A 3D printer for food processing

A 3D printer and food processing technology, applied in the field of 3D printing, can solve the problems of high cost of 3D printing equipment, unfavorable industrial production, and very high requirements, to improve the use value, avoid the phenomenon of odor, and solve the single effect of printing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

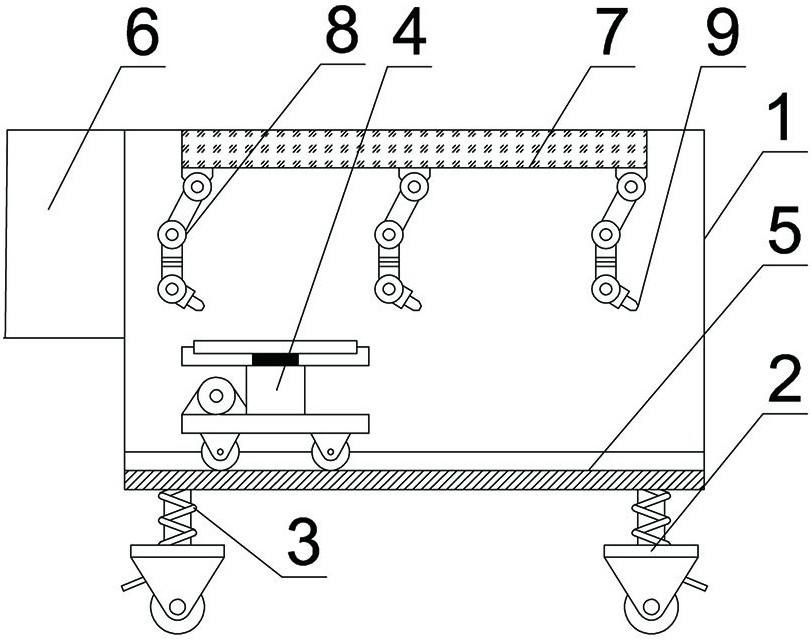

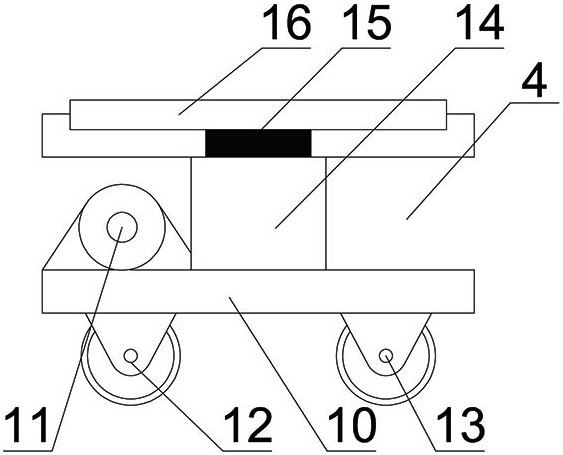

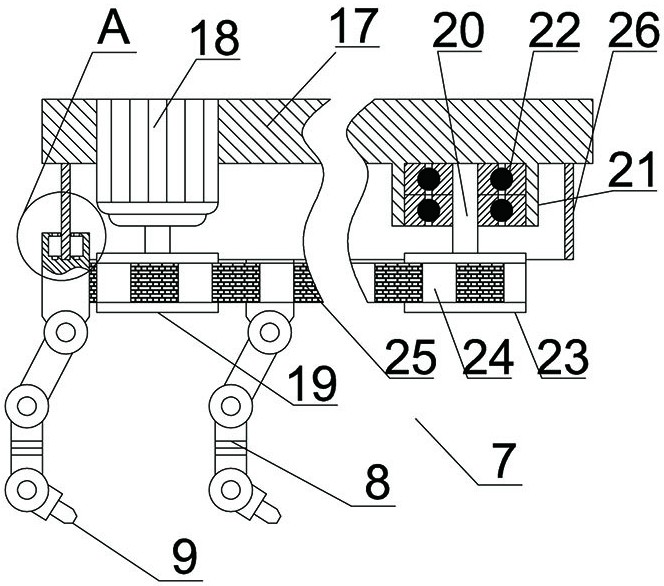

[0026] Such as Figure 1-7 As shown, this specific embodiment adopts the following technical solutions: a 3D printer for food processing, including a sealed box 1, the inner wall of the top side of the sealed box 1 is fixedly connected with a transmission frame 7, and the transmission frame 7 is connected to The bottom end of the mechanical arm 8 is fixedly connected, and the top end of the mechanical arm 8 is fixedly connected with the print head 9; Connected, the bottom of the second transmission motor 18 is rotationally connected with the driving wheel 19, the right end of the skeleton 17 is socketed with one end of the rotating shaft 20 through a rolling bearing 22, and the other end of the rotating shaft 20 is rotationally connected with the driven wheel 23, and the driving wheel 19 It is connected with the driven wheel 23 through a transmission belt 24. The outer surface of the conveyor belt 24 is uniformly fixedly connected with a plurality of second fixed blocks 25. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com