A continuously adjustable integrated anti-clogging screen device

An anti-clogging and adjustable technology, applied in chemical instruments and methods, fixed filter element filters, separation methods, etc., can solve the problems of increasing auxiliary operation time, reducing repair efficiency, and reducing porosity, so as to reduce auxiliary operation time , Enhance the dynamic adaptability and improve the confining pressure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

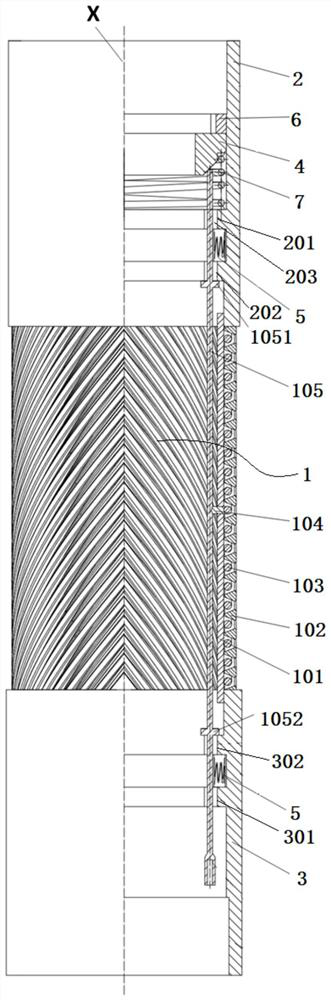

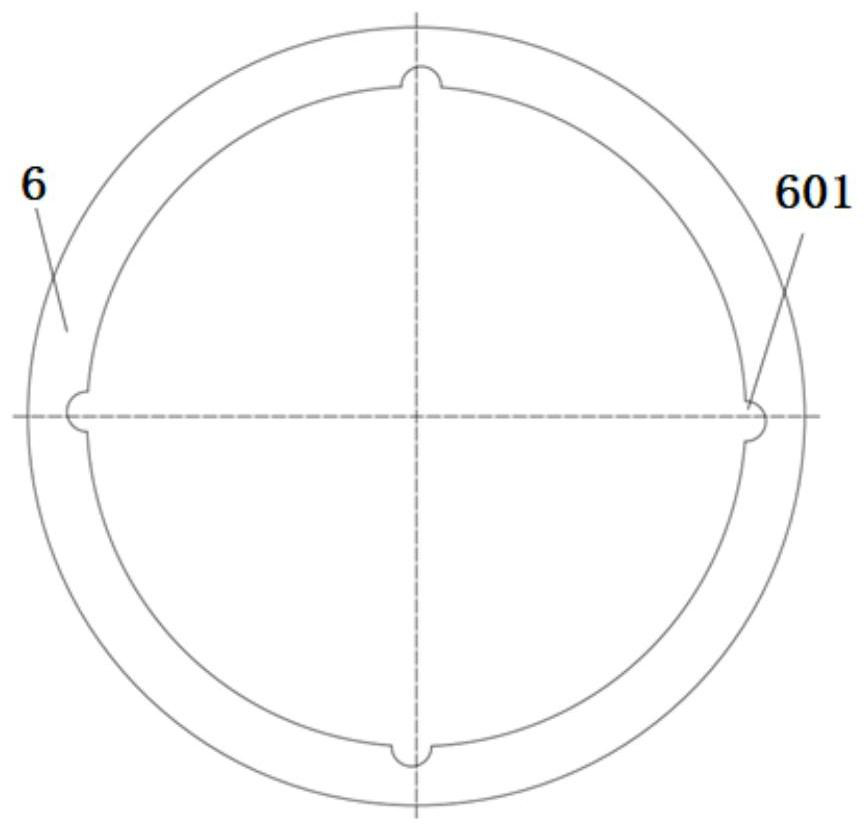

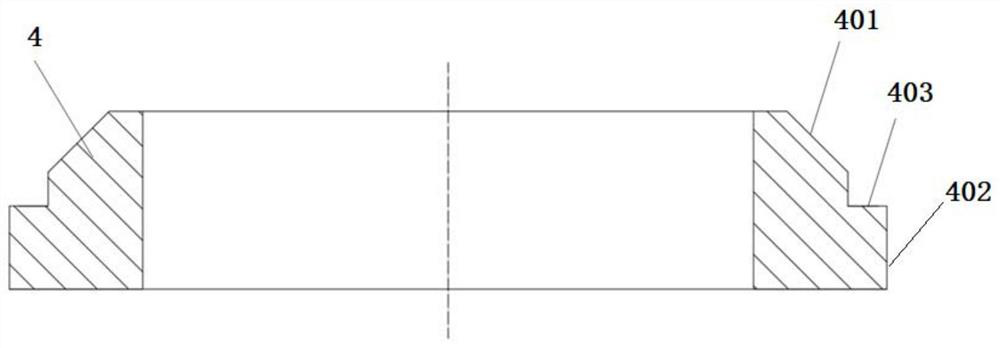

[0040] The present embodiment provides a continuously adjustable integrated anti-clogging screen device, which includes a screen frame 1 and cylindrical upper screen joints 2 and lower screen joints 3 arranged at both ends of the screen frame 1 and coaxial with each other. ; Screen skeleton 1 includes a plurality of axial skeleton lines 101, oblique skeleton lines 102 and adjustable skeleton lines 103.

[0041] The axial skeleton line 101 is connected between the upper screen joint 2 and the lower screen joint 3 and is parallel to the axes of the two, and a plurality of axial skeleton lines 101 are evenly distributed along the circumferential direction to surround the upper screen joint 2 and the lower screen joint. The screen joint 3 is a coaxial cylindrical frame; the oblique frame line 102 is connected between the upper screen joint 2 and the lower screen joint 3 and is fixed on the cylindrical frame obliquely, and the plurality of inclined frame lines 102 are uniform in the...

Embodiment 2

[0054] This embodiment provides a method for manually adjusting the porosity of a continuously adjustable integrated anti-clogging screen device. The method is implemented by the screen device in Embodiment 1. The initial state of the screen device is: under the action of a compression spring , the adjusting ring is close to the adjusting nut, and the adjusting nut is rotated to set an initial position for the adjusting ring in the axial direction. At the position of the minimum outer diameter, the axial support rod is closest to the center axis X of the screen device in the radial direction, and the adjustable skeleton line fixed with the axial support rod by welding with the radial support rod is also radially away from the center. The axis X is the closest, on the contrary, the circular section of the adjustable skeleton line is the farthest from the section of the oblique skeleton line on both sides, and the porosity of the screen device also reaches the maximum at this tim...

Embodiment 3

[0059] This embodiment provides a mechanical automatic adjustment method for the porosity of a continuously adjustable integrated anti-clogging screen device. The manual adjustment method in Embodiment 2 is suitable for determining the optimal porosity of the screen during operation according to site data and working conditions. , If it is necessary to continuously adjust the porosity of the screen in real time during the operation, it is necessary to use mechanical automatic adjustment,

[0060] The porosity mechanical automatic adjustment method includes the following steps:

[0061] Step b1, such as Figure 7 As shown, the upper screen joint of the screen device is connected with the outer pipe 8 of the upper well string, and the lower screen joint is connected with the outer pipe 9 of the lower well string and placed in the working position in the well, inside the outer pipe 8 of the upper well string. A driving rod body 10 with a central through hole is provided. The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com