Patents

Literature

34results about How to "Cleanup impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

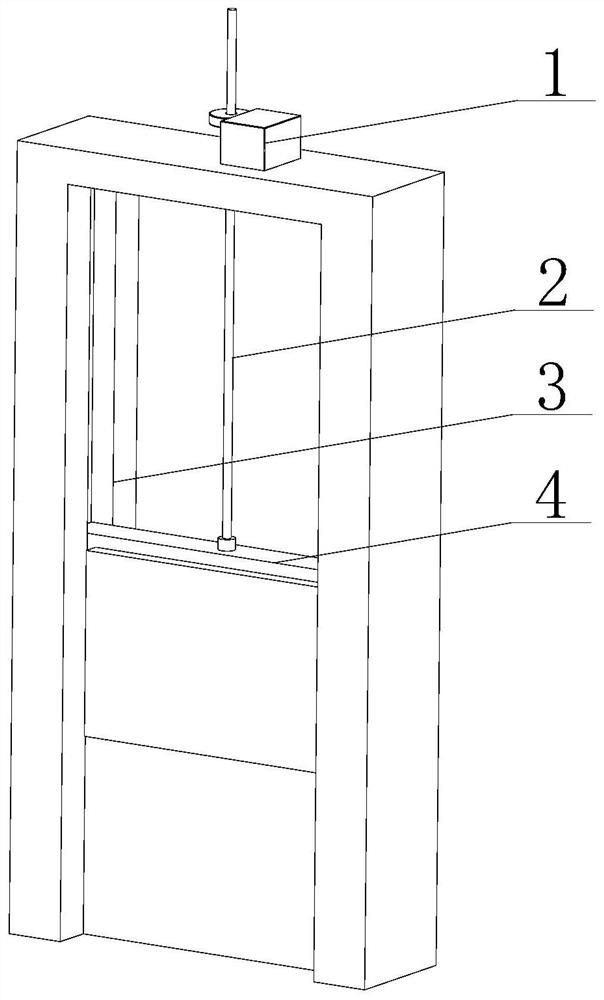

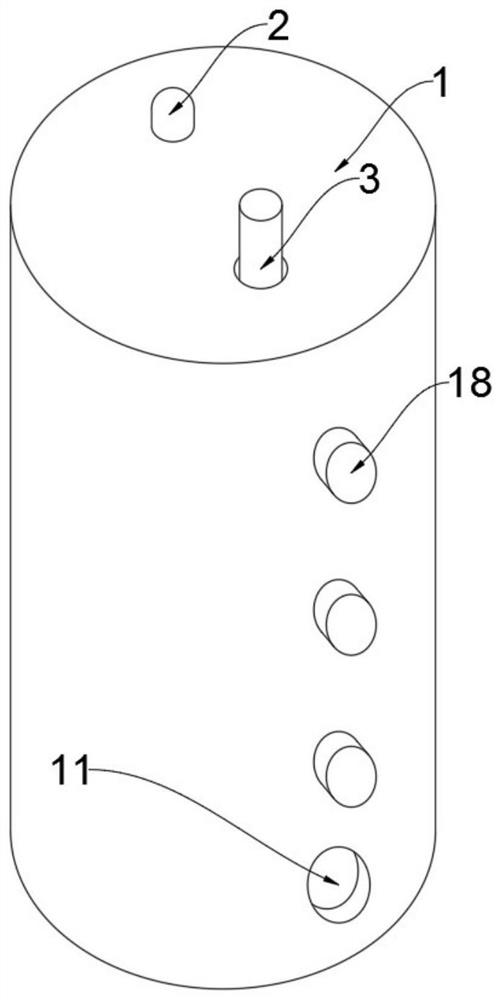

Textile fabric and yarn quick winding, coiling and uncoiling device

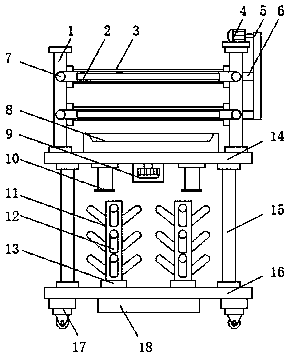

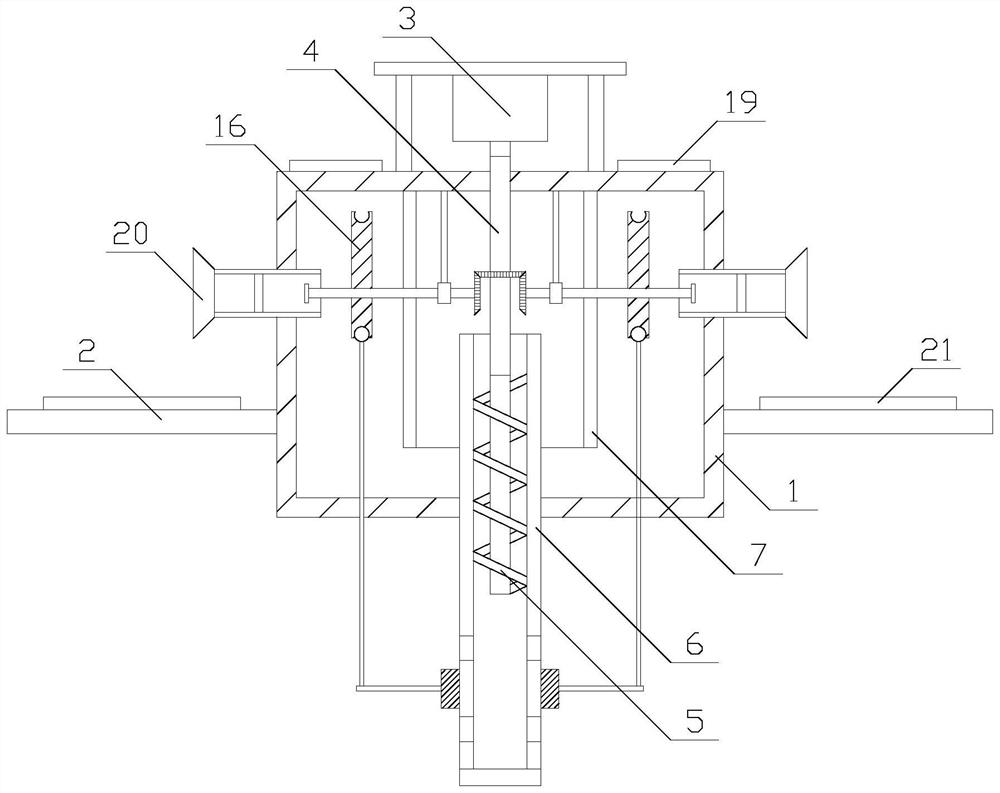

The invention discloses a textile fabric and yarn quick winding, coiling and uncoiling device. The textile fabric and yarn quick winding, coiling and uncoiling device comprises a first support plate,wherein first support columns are arranged at both ends of the surface of the first support plate; a vertical column is arranged between the two first support columns; a guide rod is arranged on the vertical column; a second support plate is arranged on the first support plate; a first motor is arranged in the middle part of the bottom surface of the second support plate; rotary sleeves are arranged at both sides of the first motor; a rotary rod is arranged in each rotary sleeve; coiling rolls are arranged between the second support columns; one side of each coiling roll penetrates through thesecond support columns and is connected with a coiling shaft; a second motor is arranged at the upper end of the second support column near the coiling shafts; a cleaning frame is arranged between frame rods; the interior of the cleaning frame is provided with an opening. The textile fabric and yarn quick winding, coiling and uncoiling device has the advantages that the structure is simple, and the convenience in use is realized; the fabrics and yarns can be quickly wound into coils, and the yarn columns can be conveniently stored; the working efficiency is improved, and the labor intensity is reduced.

Owner:湖州泰鑫无纺布有限公司

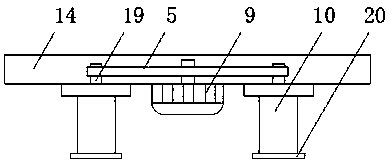

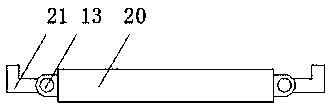

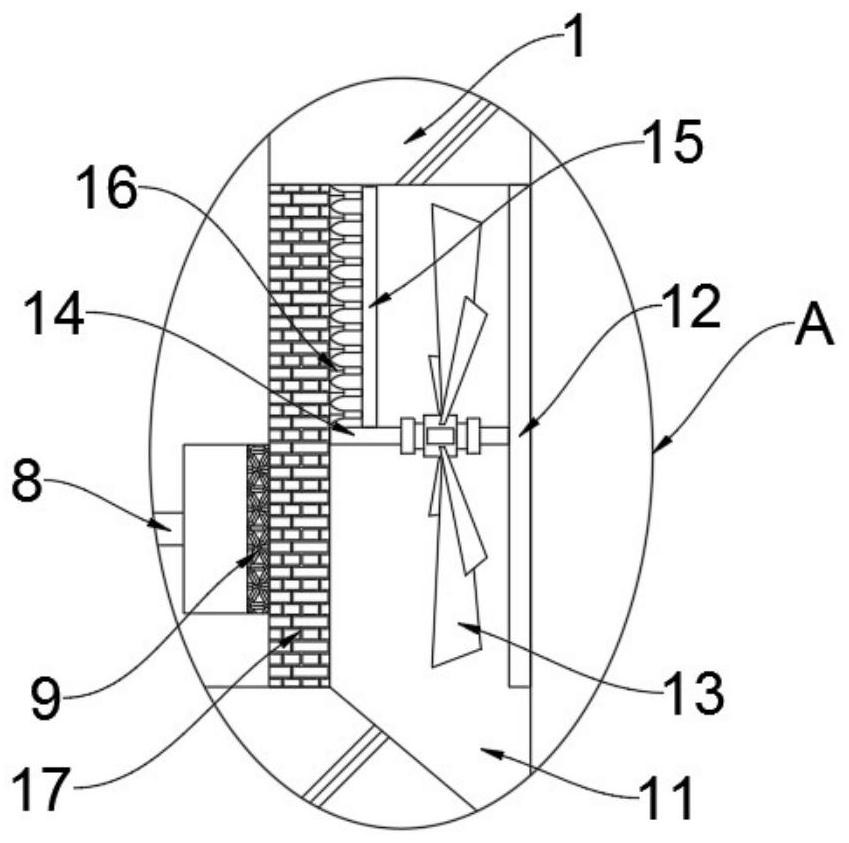

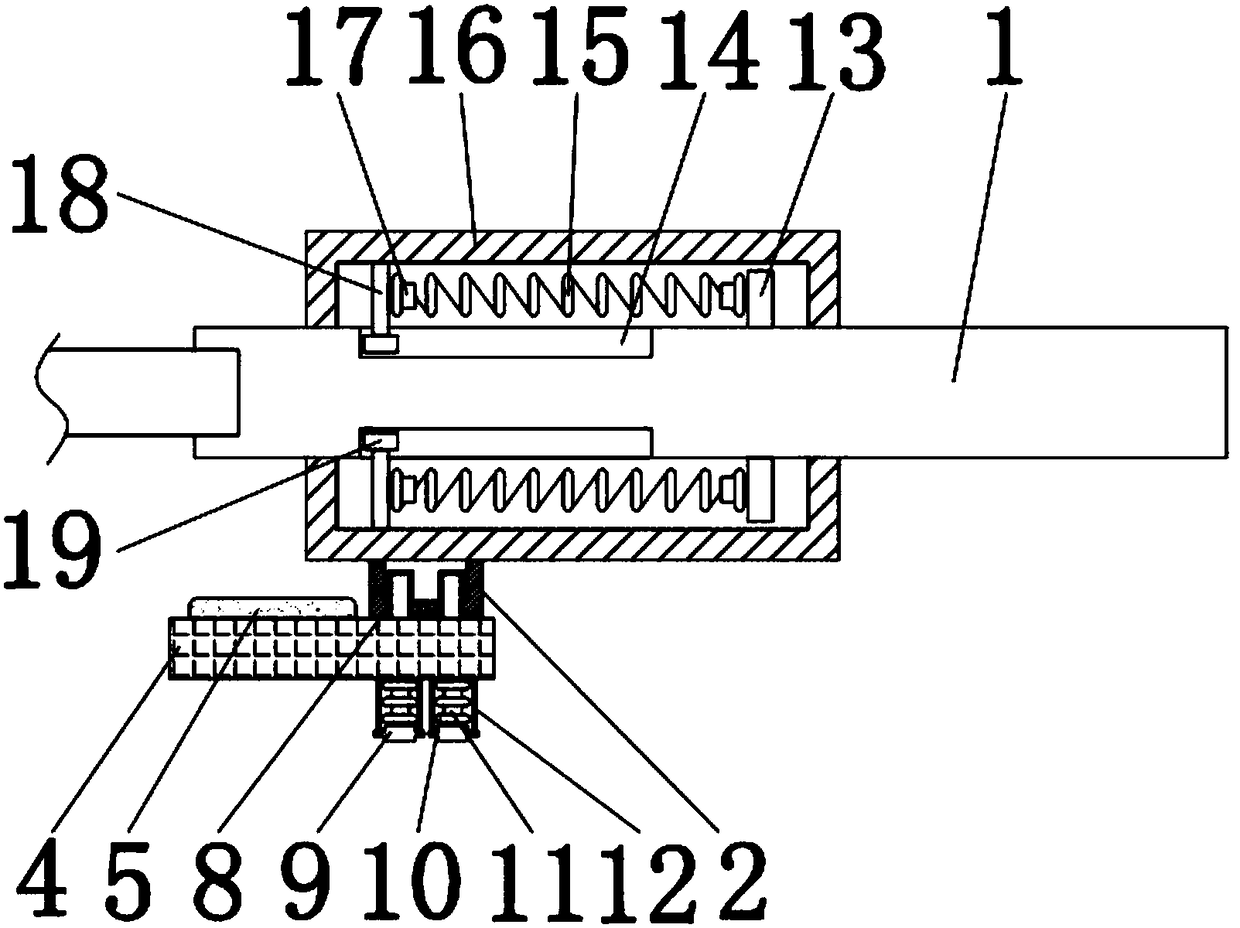

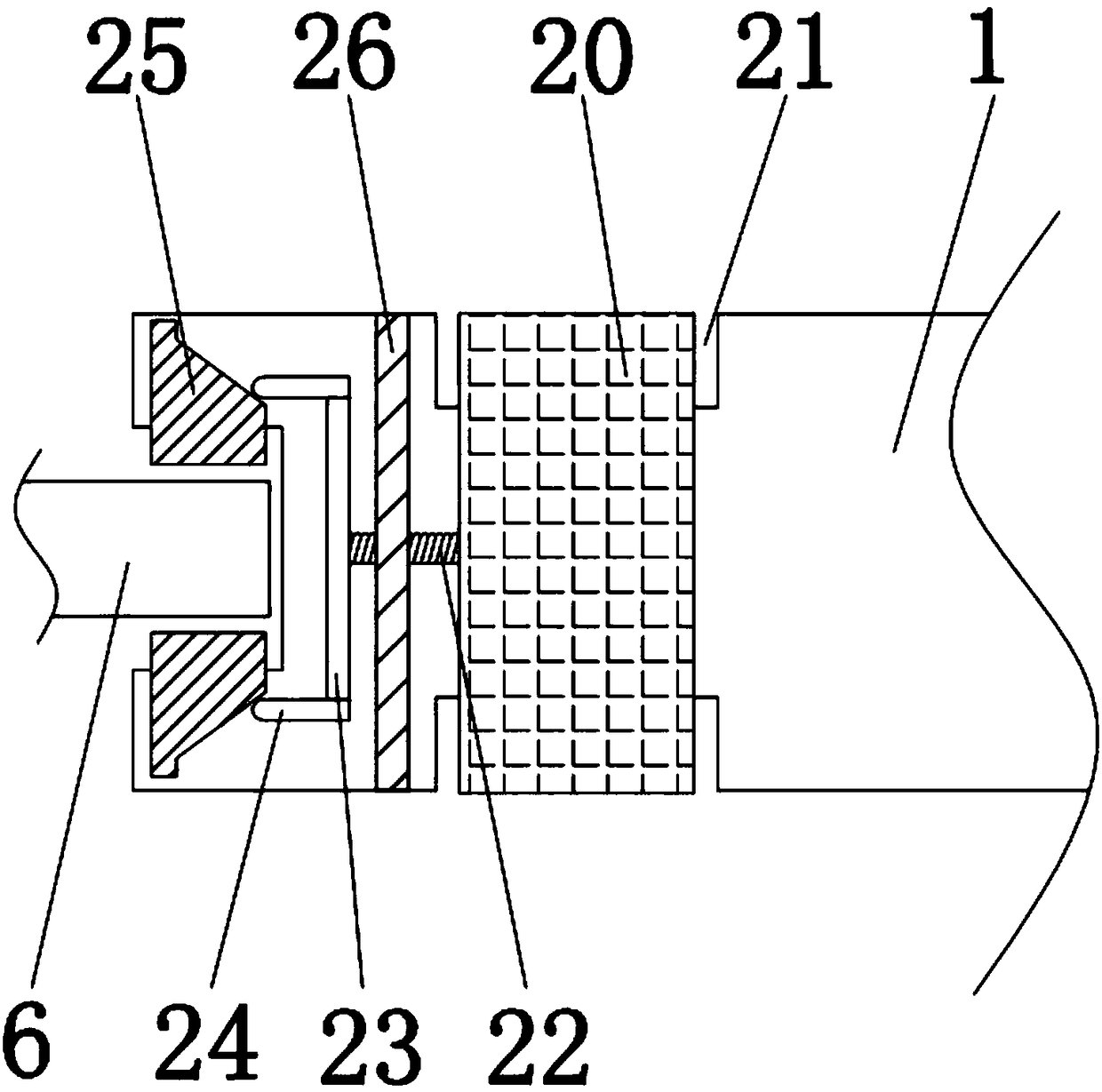

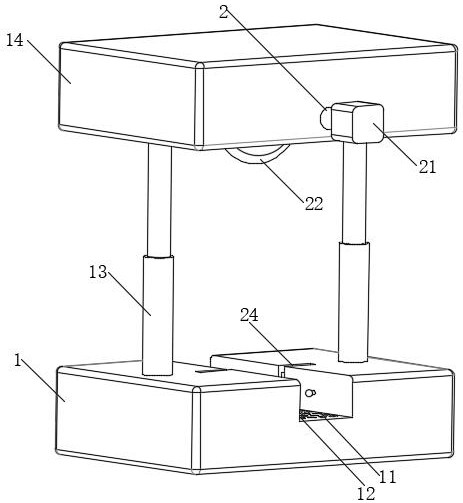

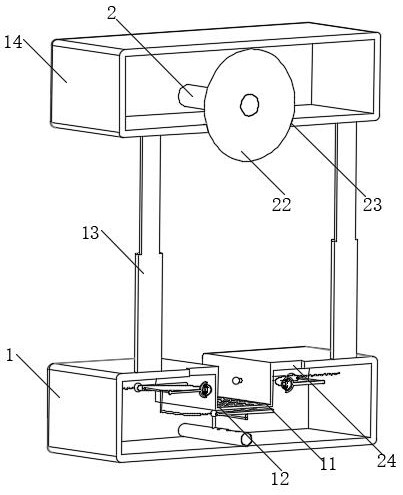

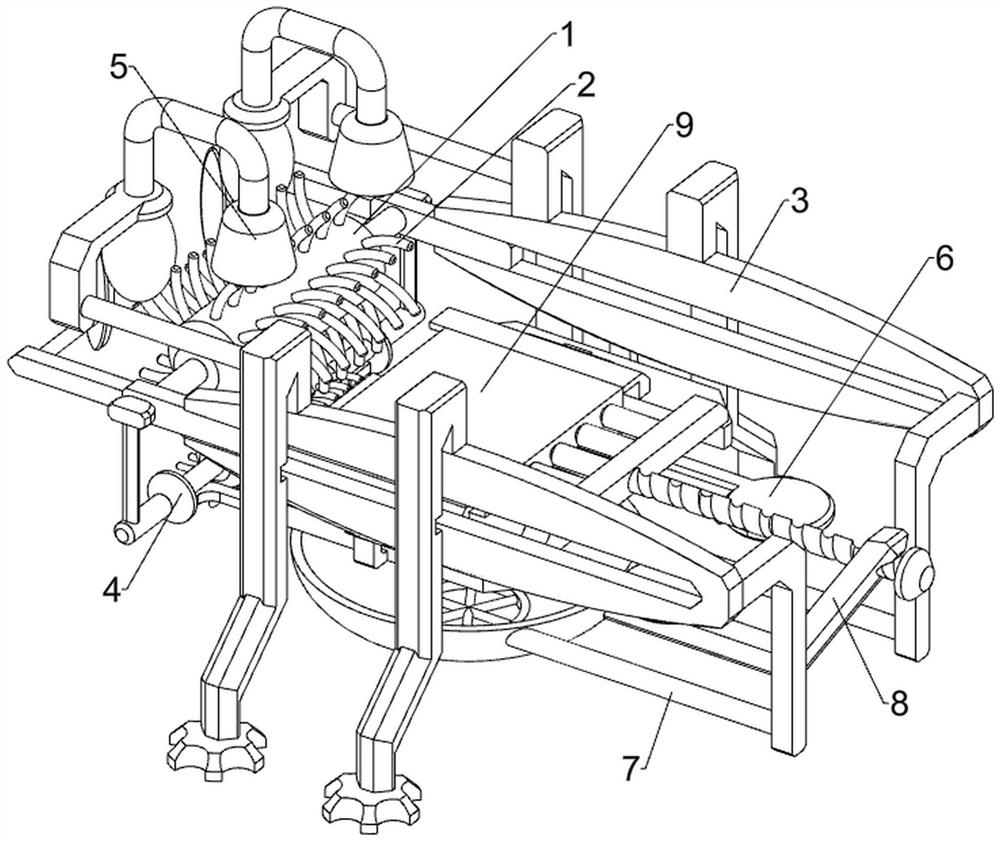

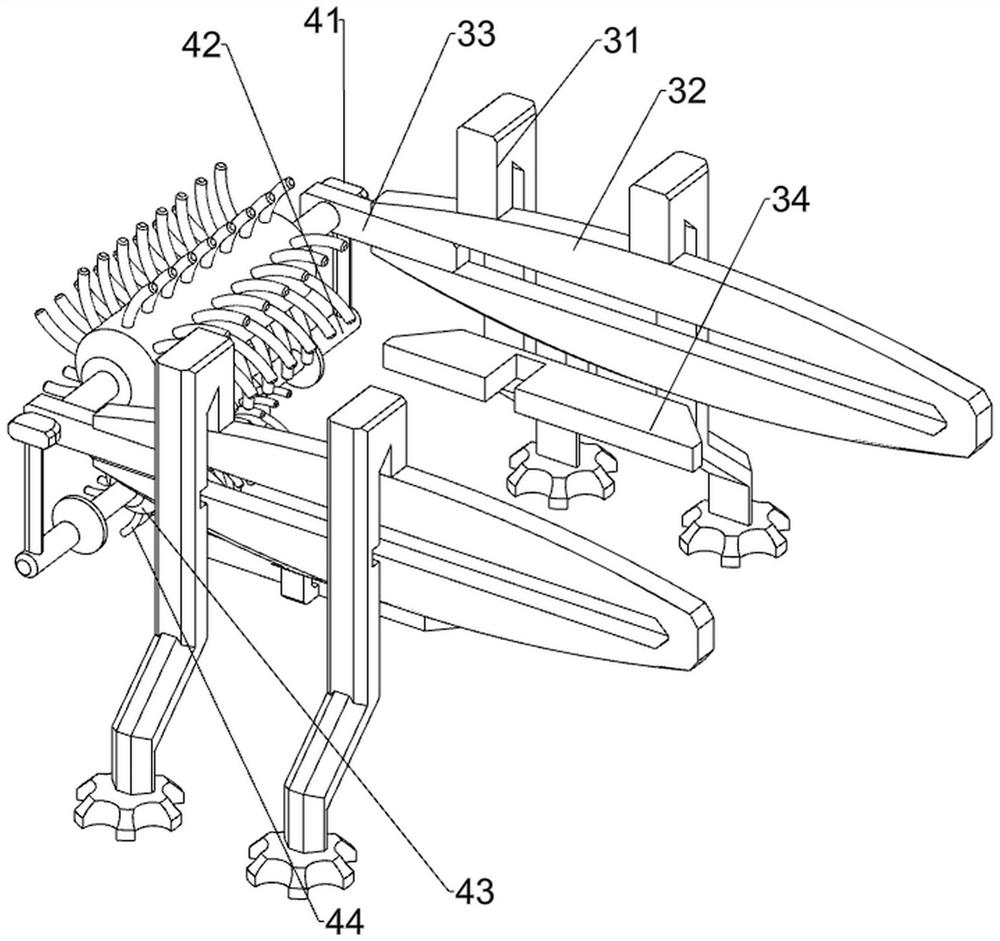

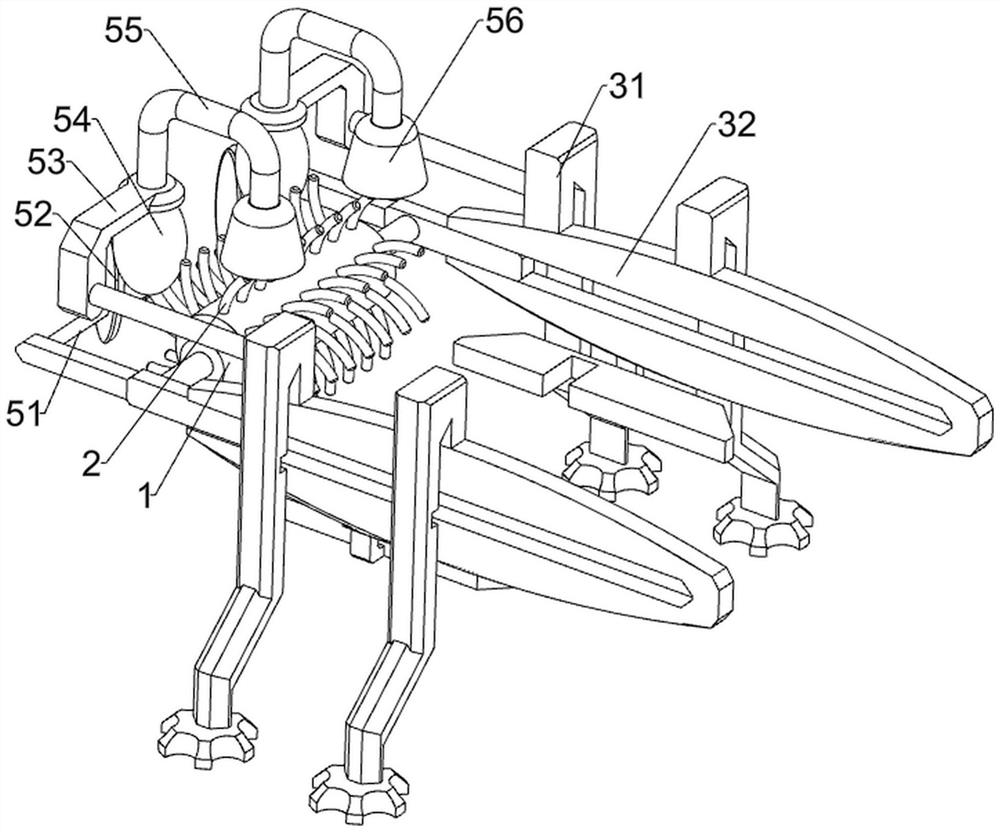

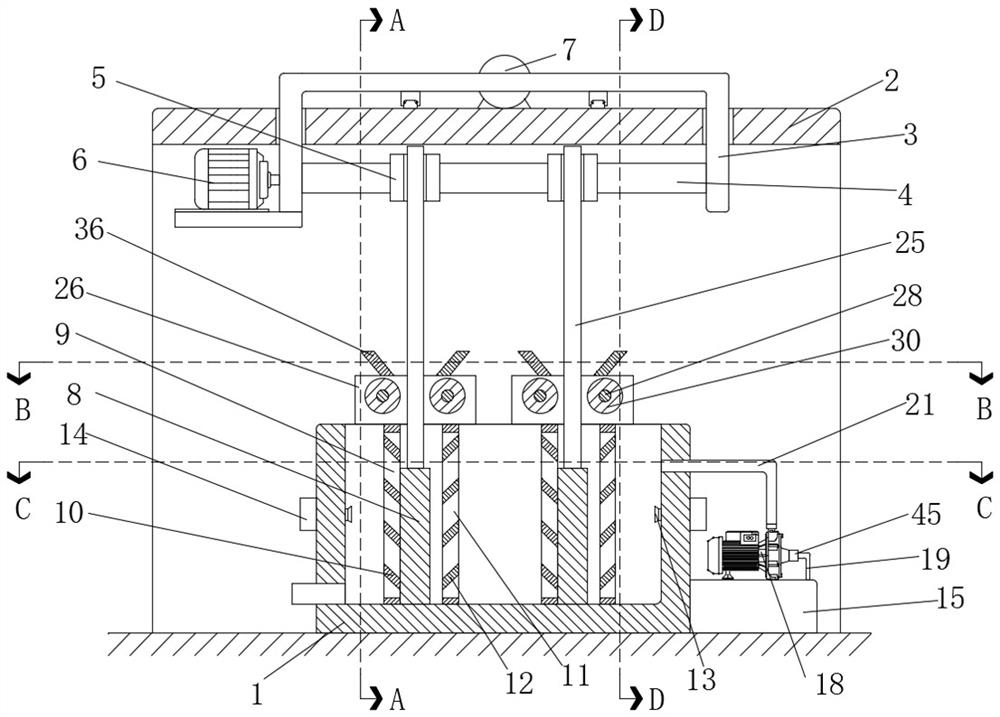

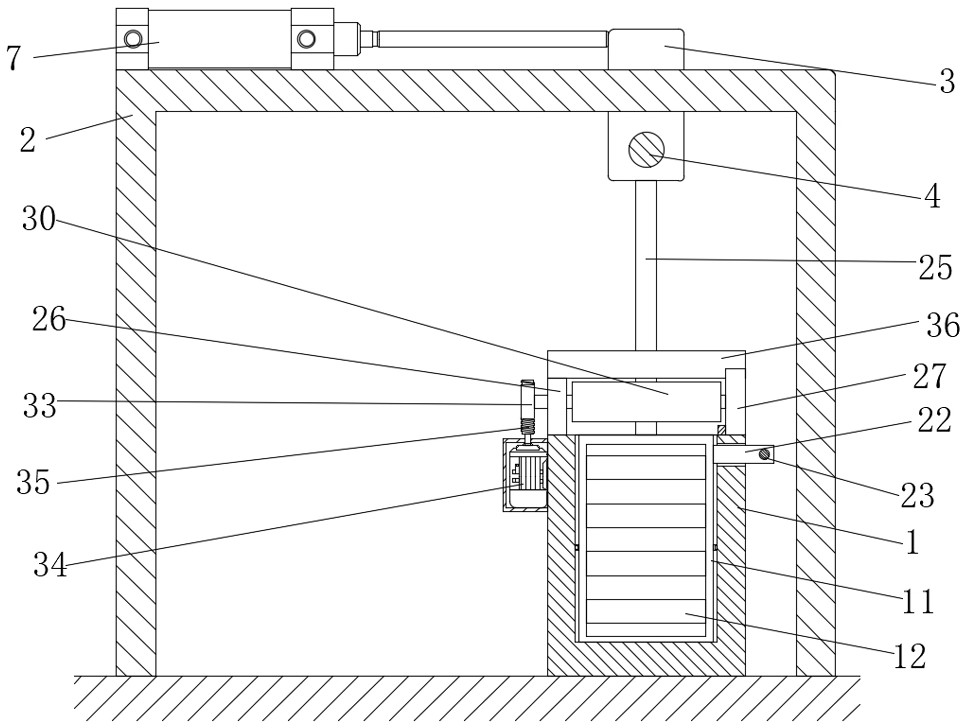

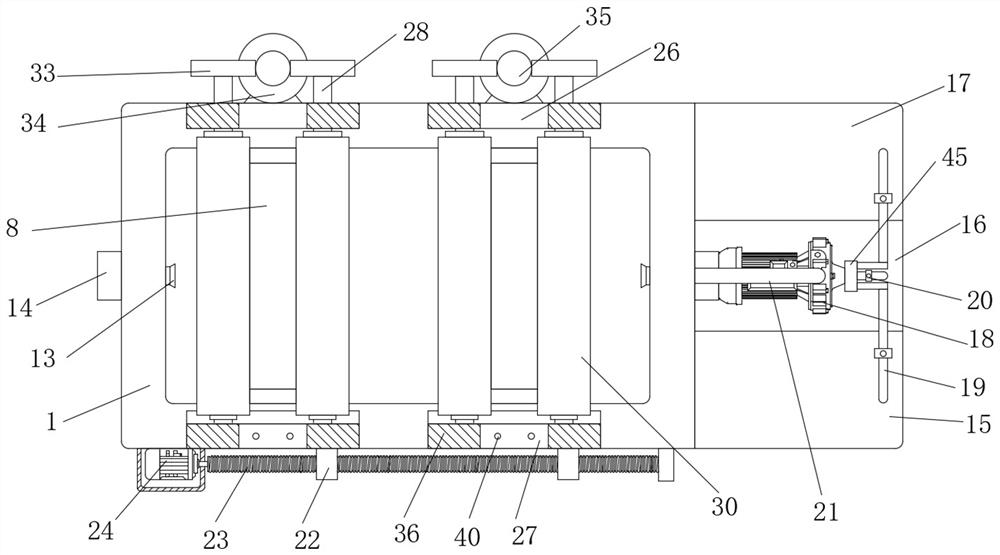

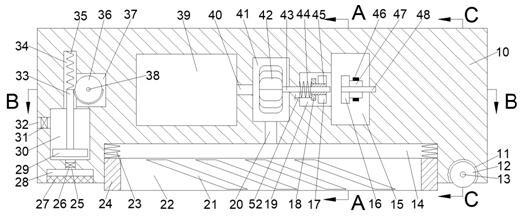

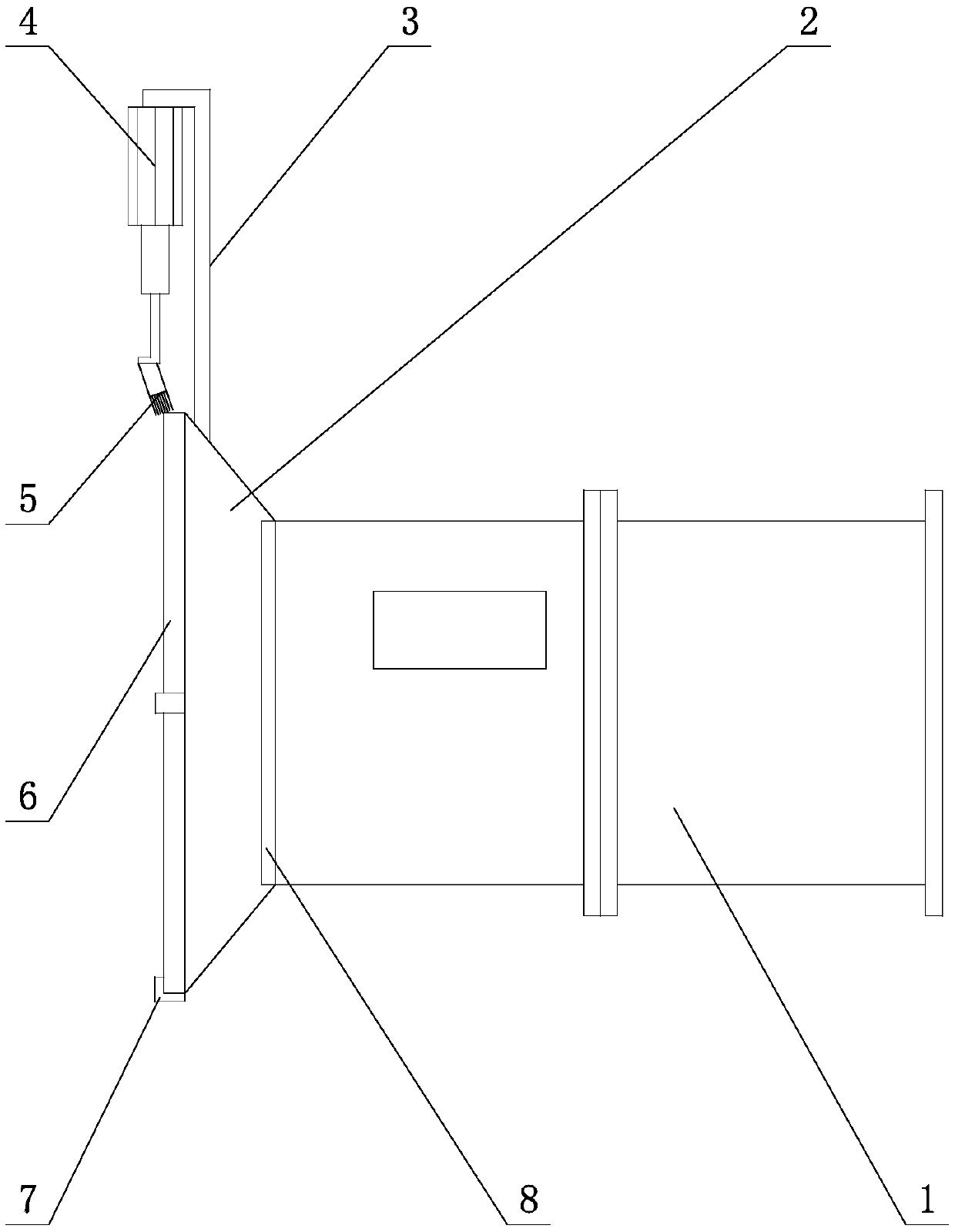

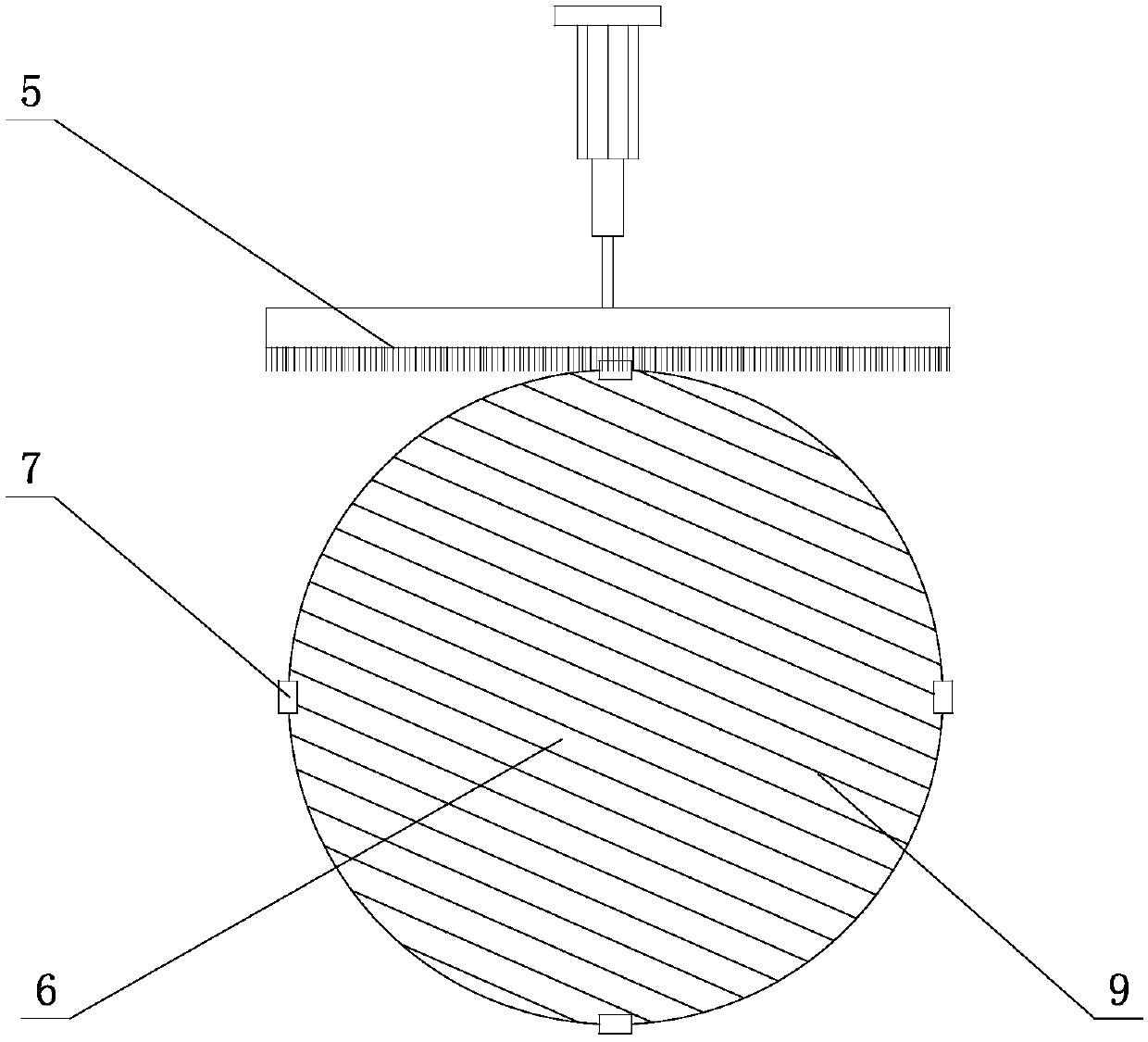

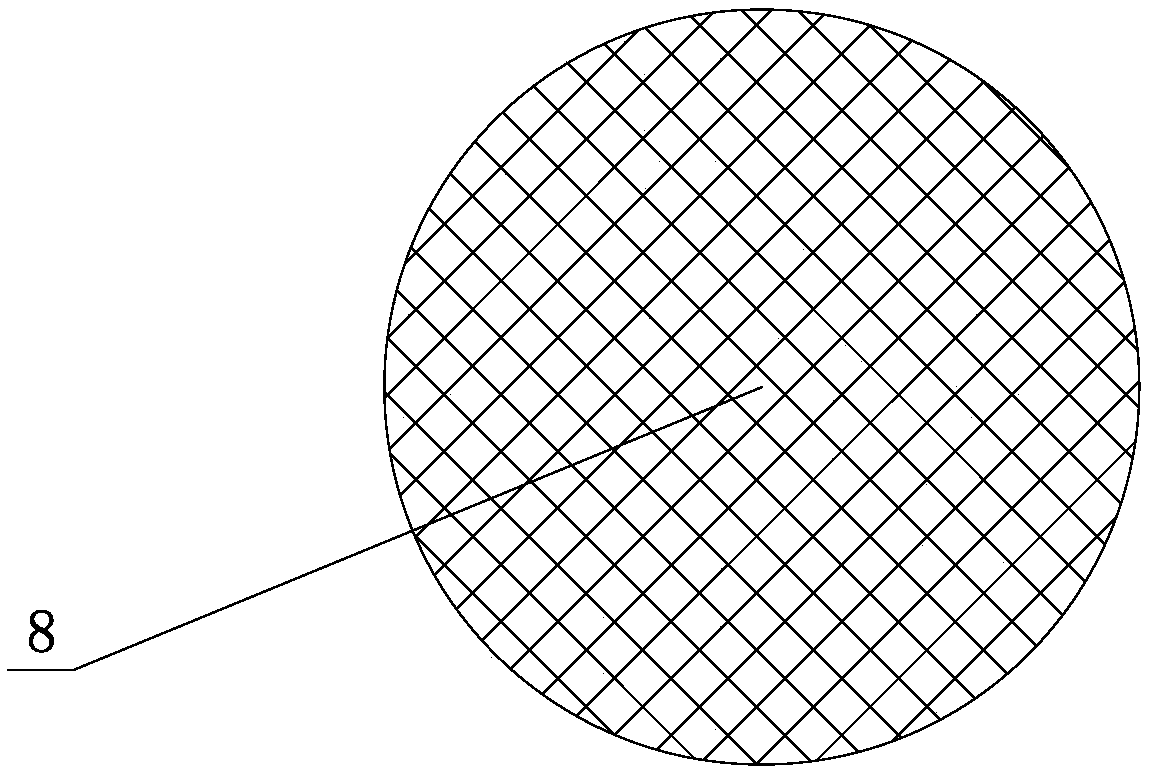

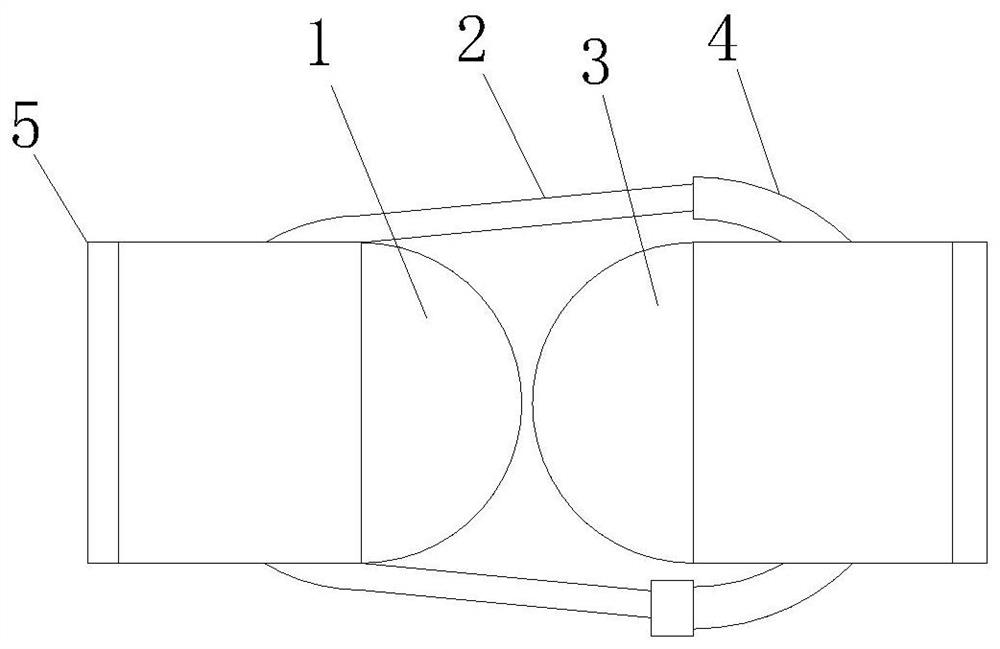

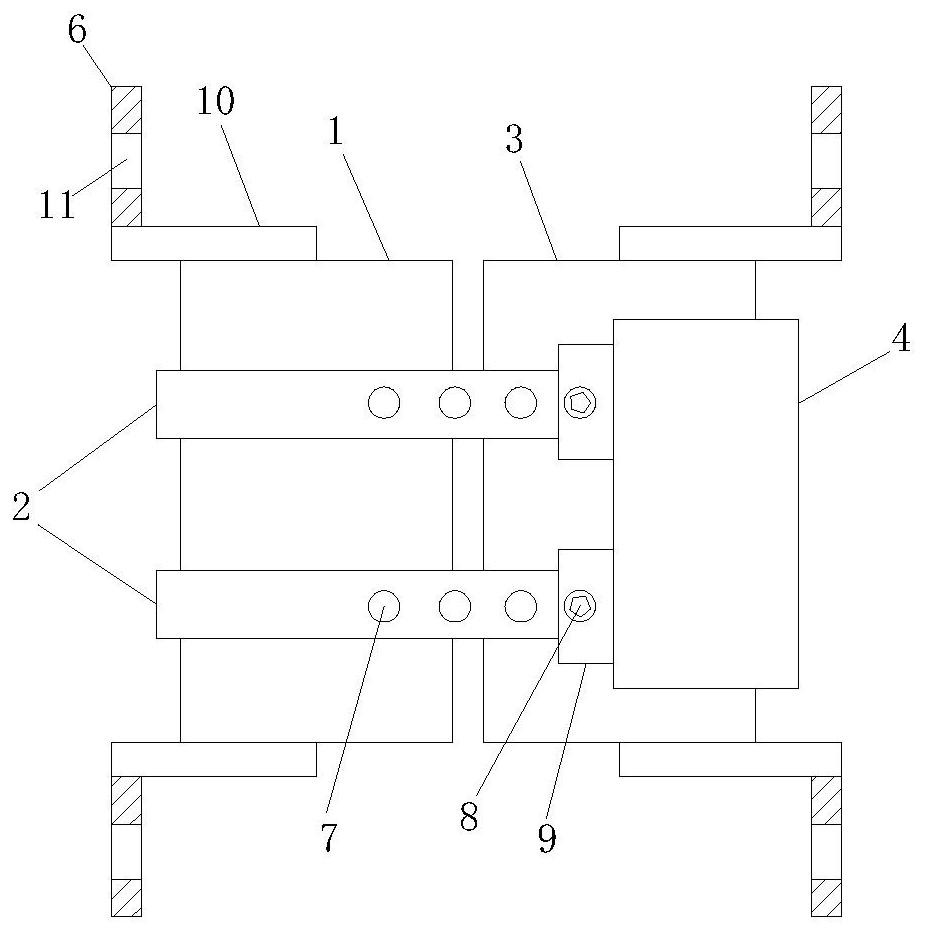

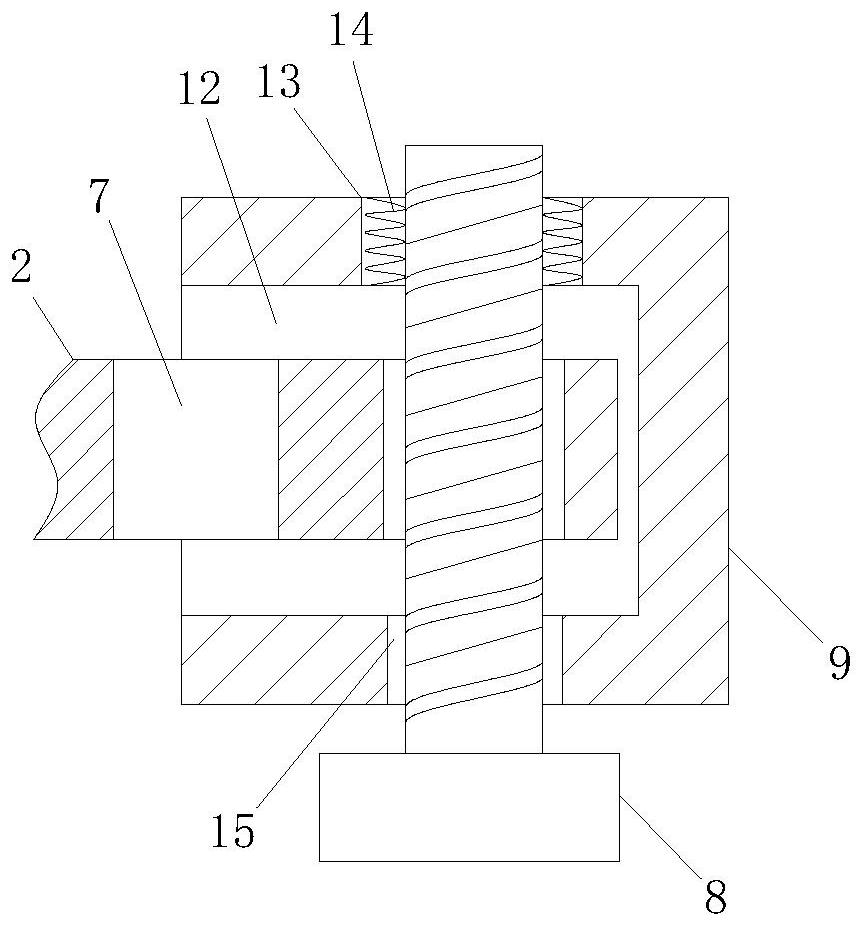

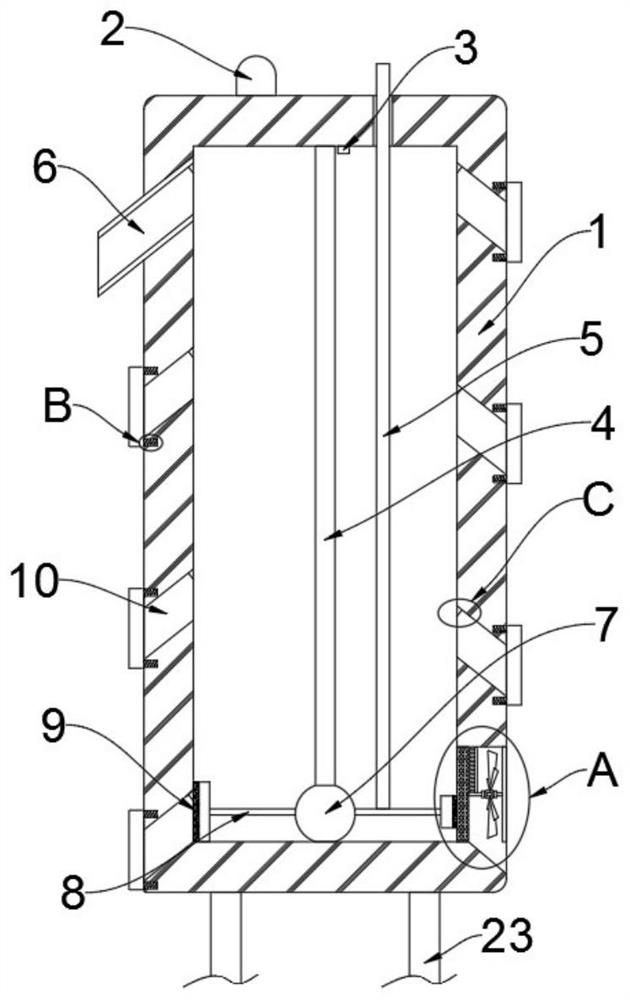

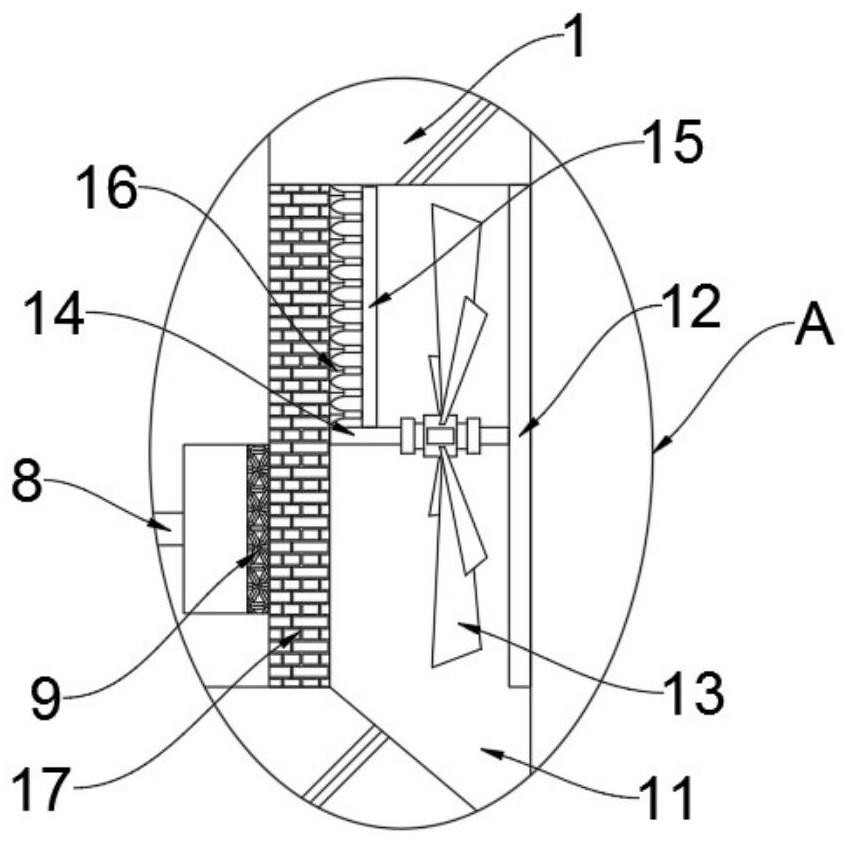

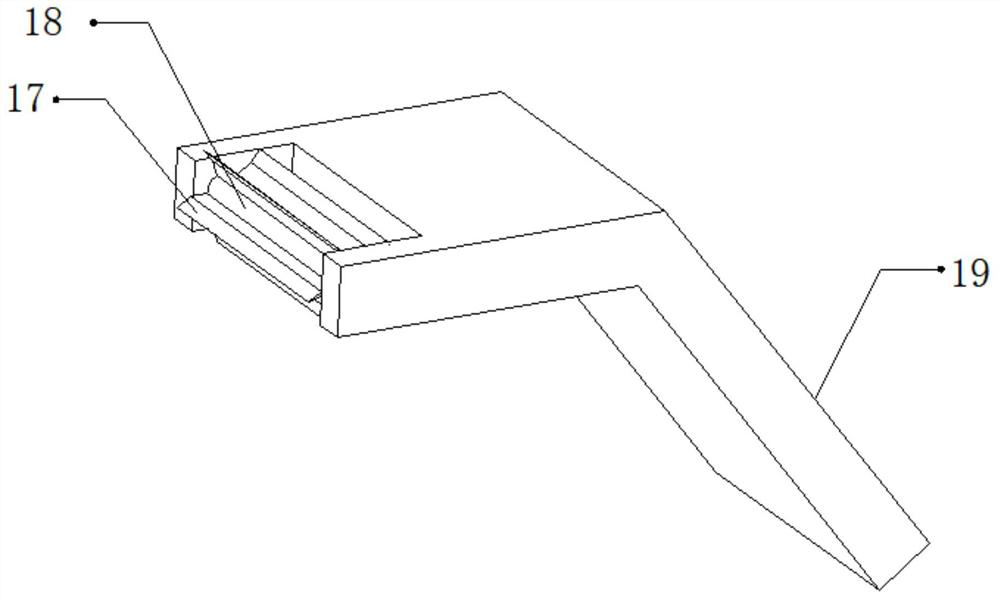

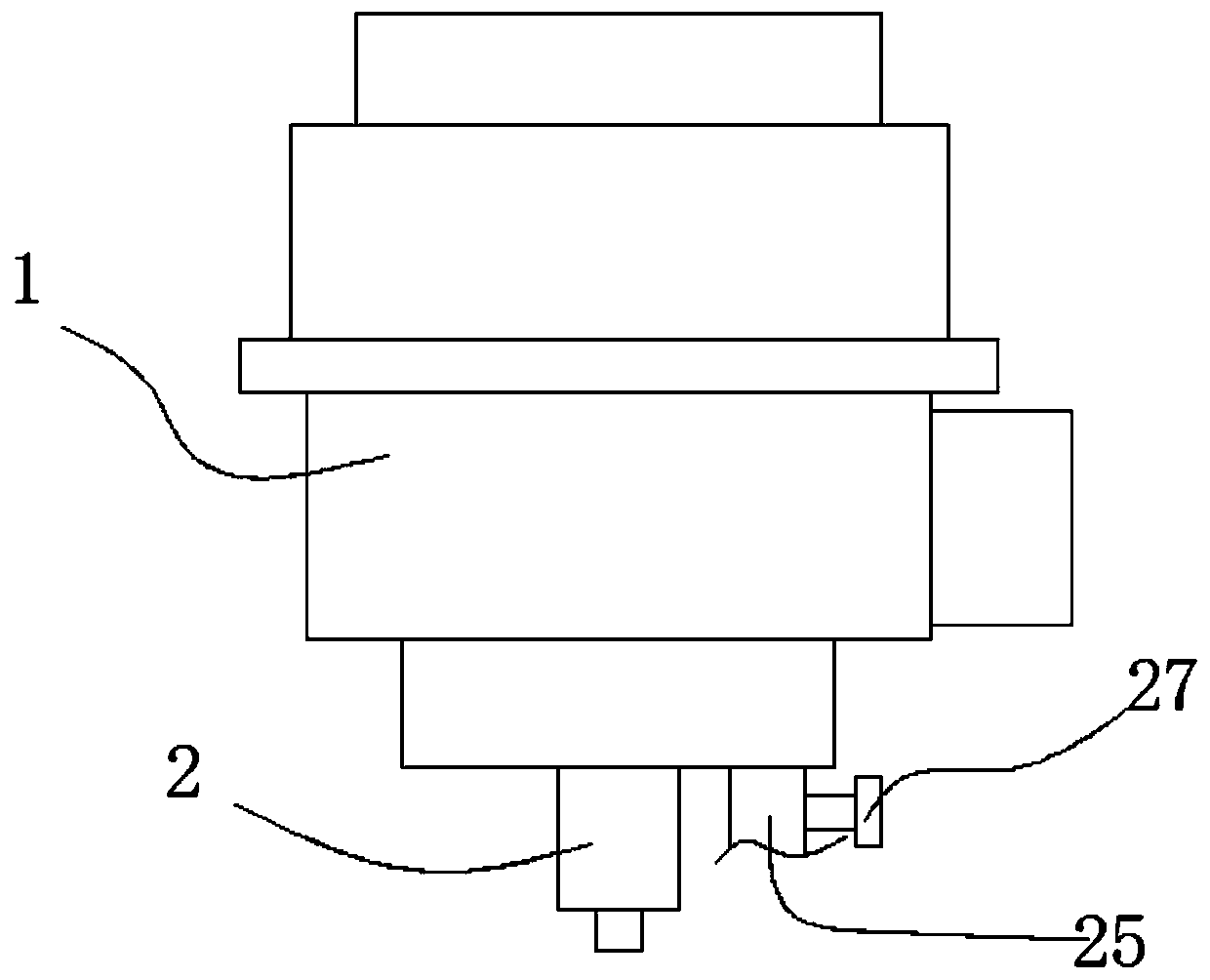

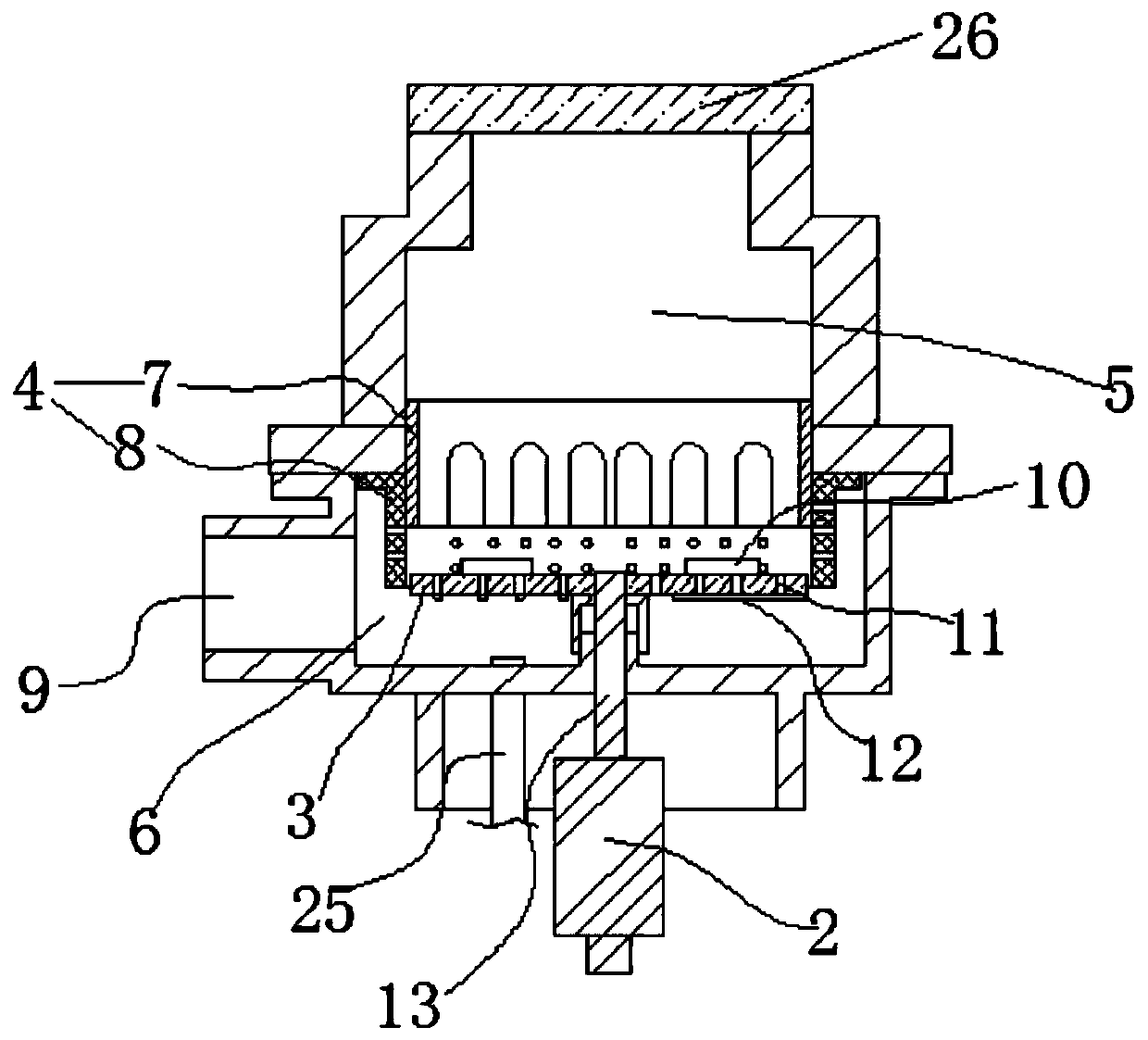

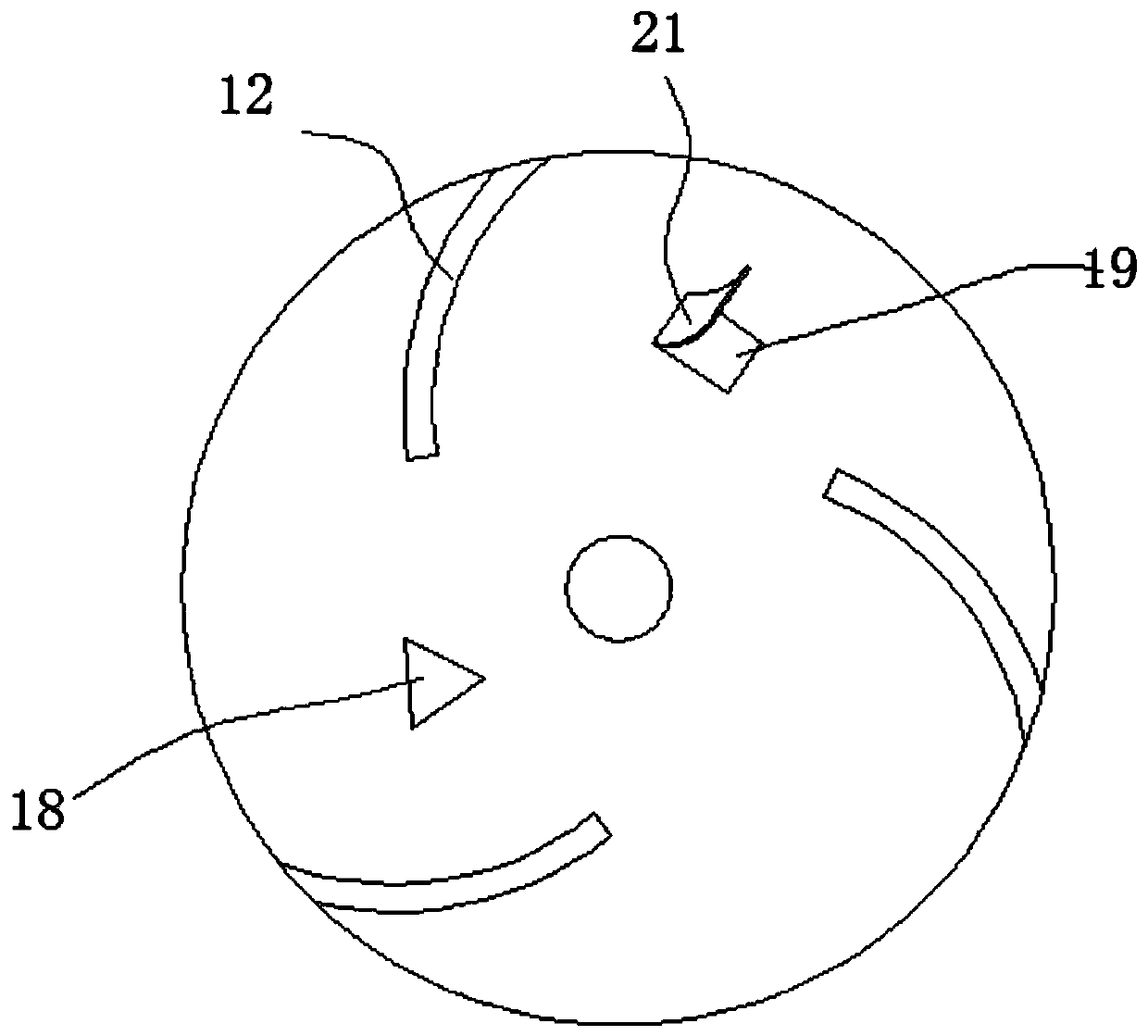

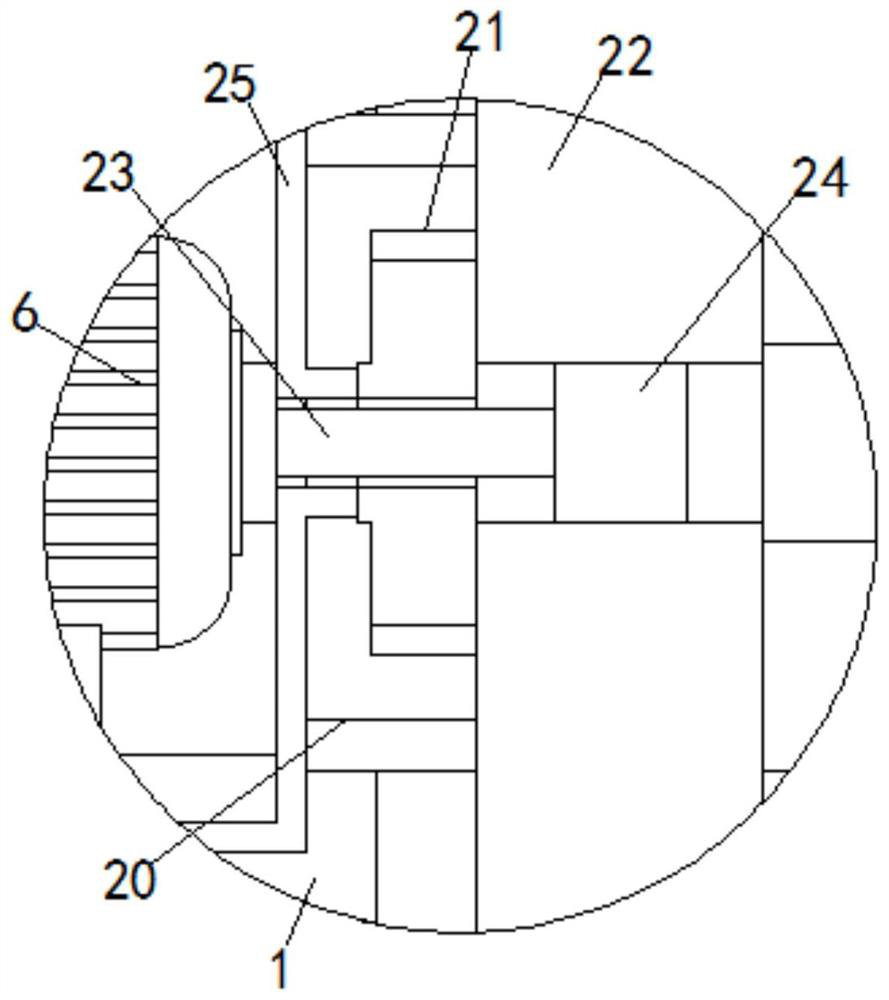

Adjustable cloth feeding hairbrush device for spinning and use method thereof

ActiveCN110790059ACleanup impactHealth hazardMechanical cleaningPressure cleaningSpinningMaterials science

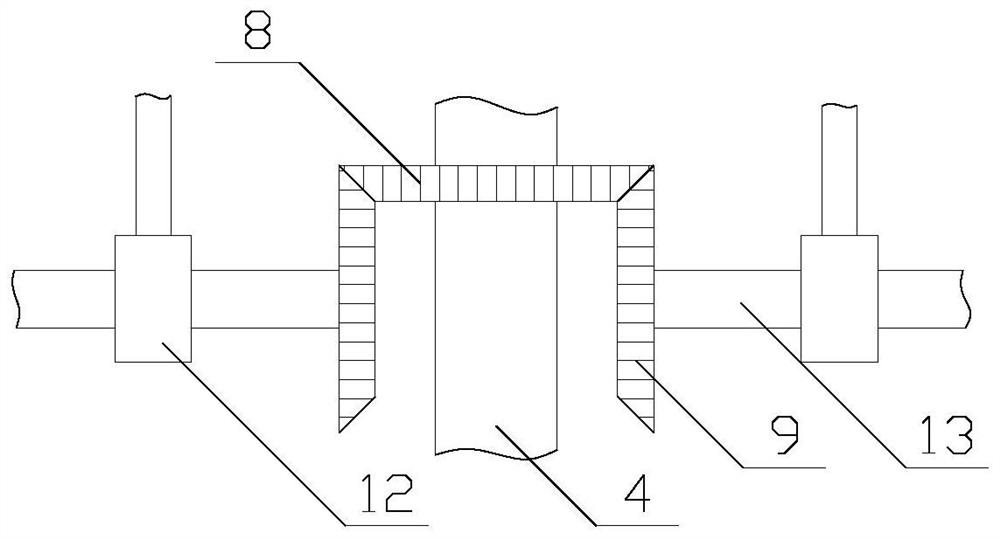

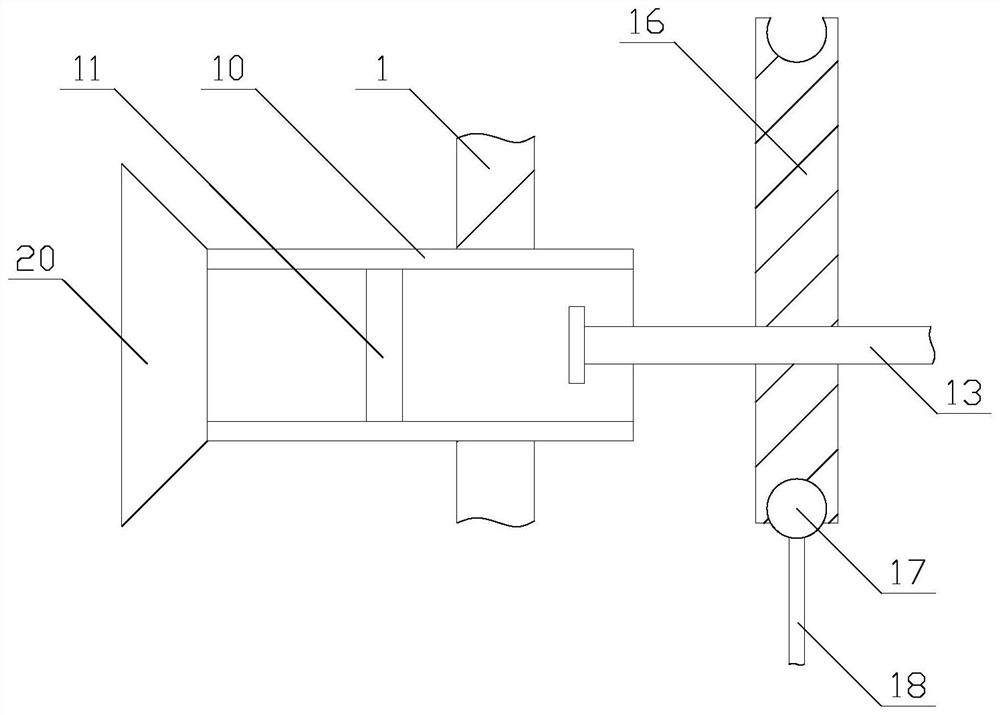

The invention discloses an adjustable cloth feeding hairbrush device for spinning and a use method thereof. The adjustable cloth feeding hairbrush device for the spinning comprises a bottom seat, a drive roller and a driven roller, wherein vertical plates are symmetrically and fixedly connected with the upper end of the bottom seat, an adjusting device used for adjusting the position of the drivenroller is installed on the bottom seat, and a first drive device used for driving the driven shaft to rotate is installed on a double-shaft motor. The invention further provides a use method of the adjustable cloth feeding hairbrush device for the spinning. The use method of the adjustable cloth feeding hairbrush device for the spinning includes the following steps: S1, checking if all device parts on the cloth feeding hairbrush device are undamaged; and S2, enabling textile cloths to pass through space between the drive roller 3 and the driven roller 4. By arranging a telescopic rod rotatably connected with the side wall of a fixing block, adjusting the telescopic rod to separate a third tapered gear from a fourth tapered gear, and then adjusting an interval between the drive roller andthe driven roller through an adjusting air cylinder, the adjustable cloth feeding hairbrush device for the spinning can perform corresponding adjustment on the thickness of the different textile cloths, and prevents the phenomena that the textile cloths are jammed and cloth feeding effects for the textile cloths are not obvious from occurring.

Owner:绍兴柯桥友和纺织品有限公司

Seed cleaning device for agricultural processing

InactiveCN111672819AAvoid breakingEasy to cleanSievingSeed and root treatmentAgricultural engineeringEngineering

The invention discloses a seed cleaning device for agricultural processing. The seed cleaning device for agricultural processing comprises a cleaning box, a drainage pipe is arranged on the outer wallof the bottom of the cleaning box, a sealing cover is arranged on the outer wall of the drainage pipe, a box cover is fixed to the outer wall of the top of the cleaning box, a filter funnel is fixedbetween the box cover and the cleaning box, a rotating rod is rotationally connected to the inner wall of the top of the box cover through a bearing, a stirring shaft is fixed to the outer wall of therotating rod, an annular groove is formed in the outer wall of the stirring shaft, the inner wall of the annular groove is sleeved with a protective sleeve, a motor is fixed to the outer wall of thetop of the box cover, and one end of an output shaft of the motor is connected with the rotating rod through a bolt. According to the seed cleaning device, the situation that the epidermis of seeds isdamaged due to large force generated during stirring can be prevented, the situation that the seeds are stacked together due to the high falling speed of the seeds, and consequently seed stirring isaffected can be prevented, and the situation that the seeds are stacked together, and the surface of a screening net is blocked can be prevented.

Owner:任静

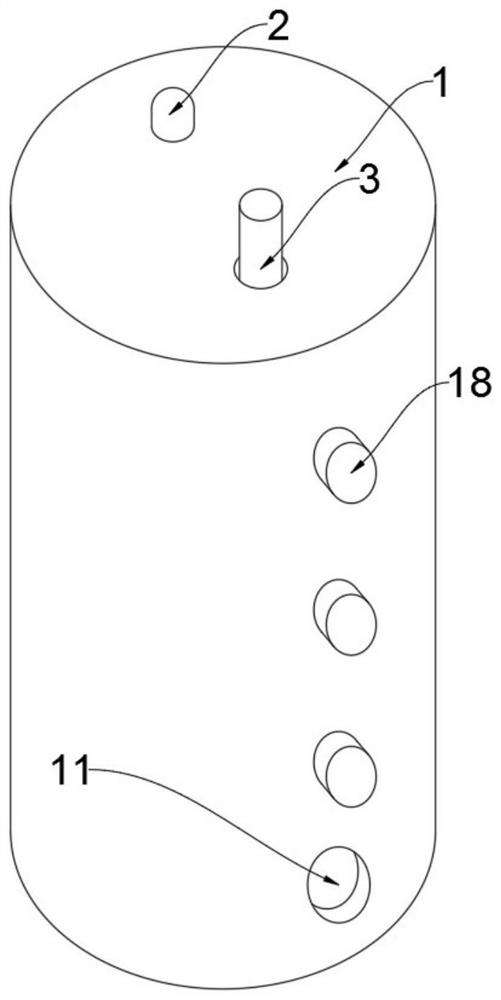

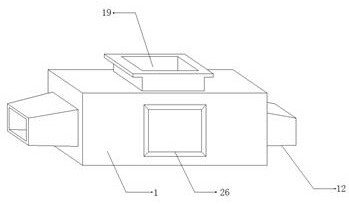

Online flood monitoring and alarming system applied to cities

ActiveCN112562269AImprove work efficiencyCleanup impactHuman health protectionFouling preventionAgricultural scienceWater flow

The invention discloses an online flood monitoring and alarming system applied to cities. The system comprises a box body and an alarm; a switch button is fixedly connected to the top of the inner side wall of the box body, a sliding rod is fixedly connected to the inner side wall of the box body, a floating ball is slidably connected to the outer side wall of the sliding rod, and a floating plateis fixedly connected to the outer side wall of the floating ball. The outer side wall of the floating plate is fixedly connected with a cleaning plate. According to the system, flood is monitored andalarmed in time through the acting force of water, the inner side wall of the device is cleaned through the buoyancy effect of the water, and the situation that in-time monitoring and controlling ofthe flood by the device is influenced due to the fact that too much dirt exists on the inner side wall of the device is prevented; the outer side wall of the filter screen is cleaned through water flowing, the situation that due to the fact that the filter screen is blocked by dirt in long-term working water of the filter screen, monitoring and alarming are not conducted in time, and the masses are threatened is prevented, resources are greatly saved, and the working efficiency and timeliness of the device are improved.

Owner:CHANGAN UNIV

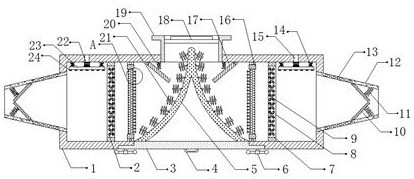

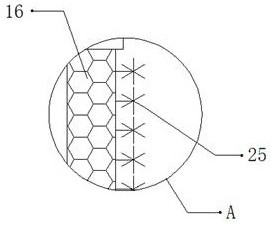

Dust removal device for cotton yarn spinning workshop

InactiveCN111974142AImprove processing efficiencyIncrease contact areaCombination devicesDirt cleaningYarnStructural engineering

The invention discloses a dust removal device for a cotton yarn spinning workshop. The device comprises a box body, exhaust ports are formed in the outer walls of the two sides of the box body, exhaust pipes are fixedly connected to the inner walls of the two exhaust ports, through openings are formed in the outer walls of the two sides of the two exhaust pipes, a filter screen is fixedly connected to the inner wall of each through hole, an air inlet is formed in the outer wall of the top of the box body, an air inlet pipe is arranged on the inner wall of the air inlet, a draught fan is fixedly connected to the inner wall of the air inlet pipe, a sinking opening is formed in the outer wall of the bottom of the box body, a fixing plate is clamped to the inner wall of the sinking opening, and threaded openings are formed in the two sides of the outer wall of the bottom of the fixing plate and the two sides of the inner wall of the top of the sinking opening. According to the device, dustand batting can be prevented from gathering together to affect the treatment efficiency of the device, batting can be prevented from falling off from the second barbs due to the fact that the flowingspeed of the dust is high, and air can be prevented from entering the device to interfere with cleaning of the dust.

Owner:杨文杰

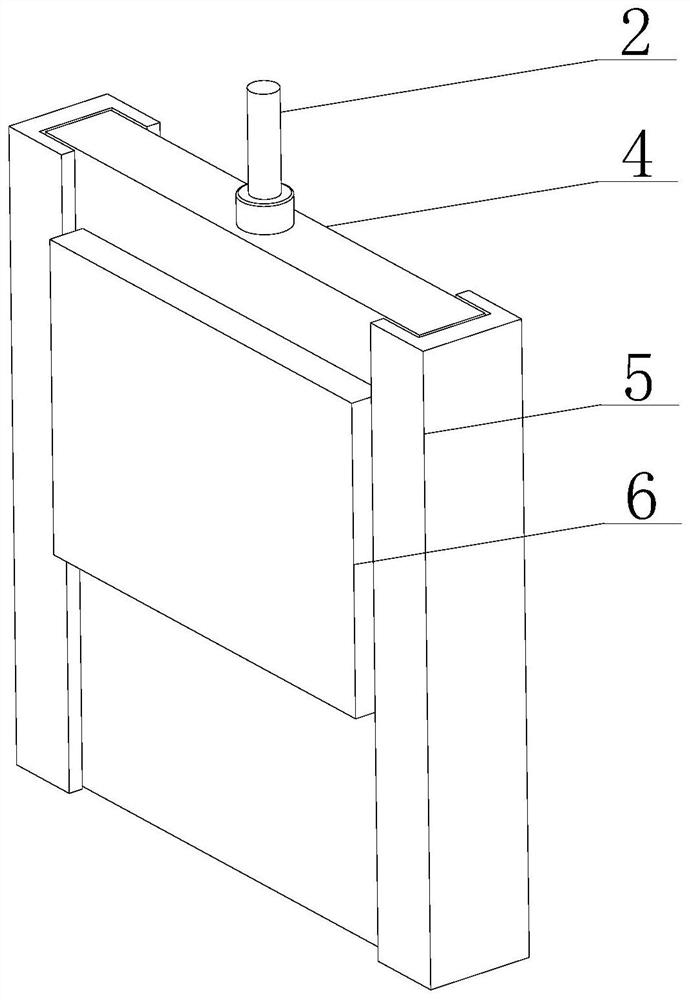

Anti-icing hydraulic engineering gate

The invention discloses an anti-icing hydraulic engineering gate, and relates to the technical field of hydraulic engineering machinery. The anti-icing hydraulic engineering gate comprises a lifting mechanism, a lifting rod, a gate frame and a gate main body, the inner wall of the gate frame is slidably connected with the gate main body, the top of the gate main body is provided with the lifting rod, the top end of the lifting rod penetrates through the top of the gate frame, a lifting mechanism is arranged on the outer wall of the lifting rod and located on the top of the gate frame, and an ice isolation mounting plate is fixedly mounted on the front face of the gate main body. By arranging a water blocking disc, a heat conduction cylinder and a friction heating rod, the water blocking disc is pushed by water flow, friction is generated between the friction heating rod and the heat conduction cylinder, so that heat is generated, by arranging a fixed interlayer plate and a heat preservation sealing frame, the heat conduction cylinder can be fixed through a fixed interlayer plate, heat on the heat conduction cylinder can be prevented from being lost, and meanwhile, the heat preservation sealing frame can further preserve the heat, so that the heat can be better transferred to a cavity plate.

Owner:段鹏鹏

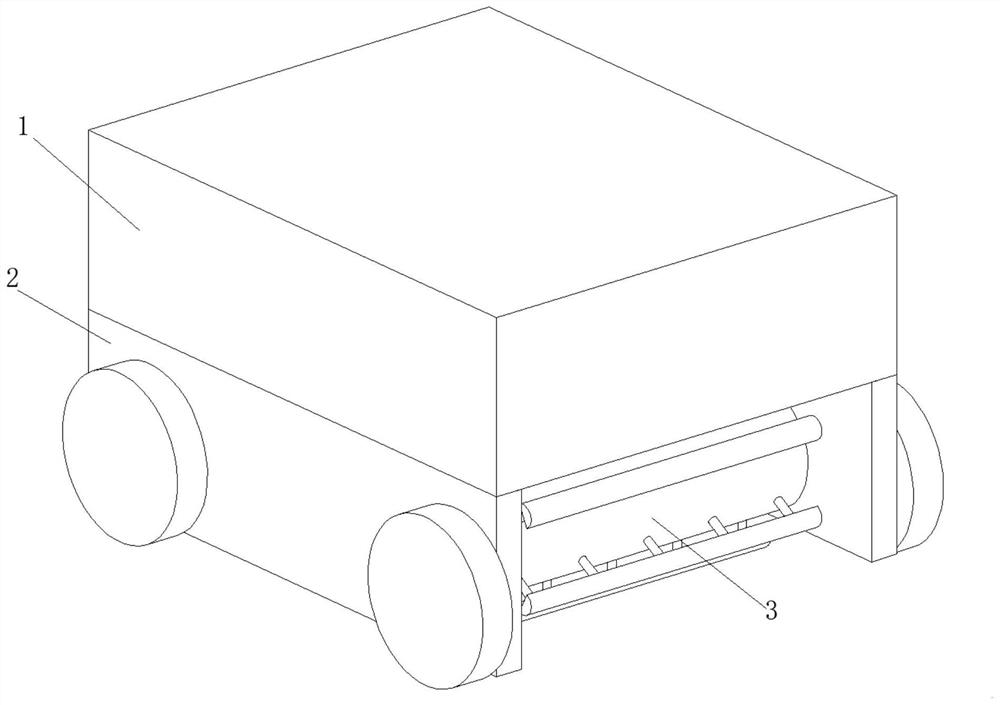

Soil cleaning device for municipal road

InactiveCN113668345APrevent slippingAvoid traffic accidentsRoad cleaningRoads maintainenceTraffic accidentSlide plate

The invention relates to the technical field of municipal gardens, and discloses a soil cleaning device for a municipal road. The device comprises a box body, two supporting plates are welded to the bottom of the box body, a cleaning mechanism, a shoveling mechanism and a collecting mechanism are arranged between the two supporting plates, and the inner wall of the box body is movably connected with a sliding plate through a spring. The cleaning mechanism comprises a roller, a limiting plate is welded to the inner wall of the roller, a transmission rod is slidably connected to the inner wall of the roller, a baffle is welded to the top end of the transmission rod, and a brush rod is welded to the bottom end of the transmission rod. According to the device, the soil tightly pressed on the ground face is scraped through the shoveling mechanism, then the cleaning mechanism is used for washing the remaining soil, so that the soil compacted by the automobile on the road can be cleaned, and then the situation that in rainy days, after rainwater makes contact with the soil, the automobile slips, and traffic accidents are caused can be prevented.

Owner:邓洁雨

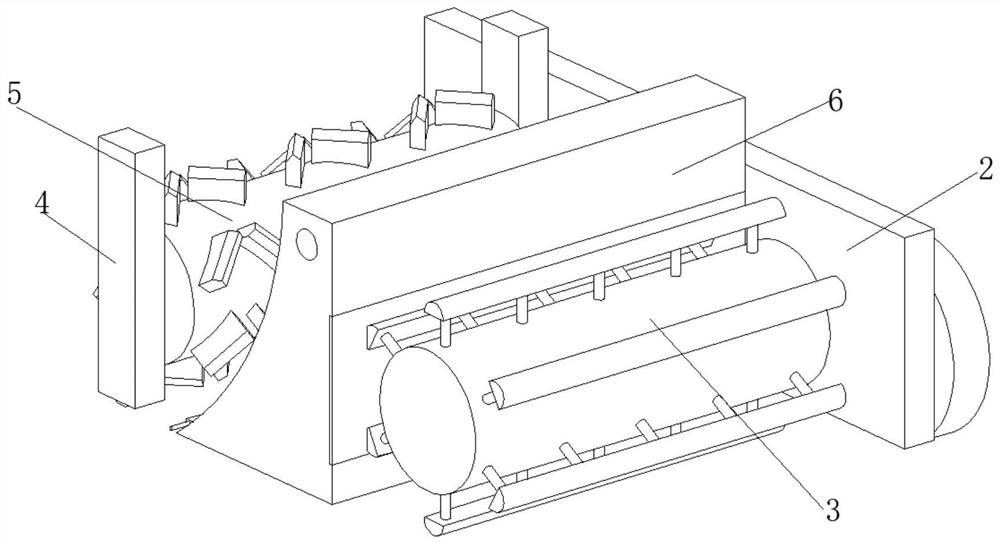

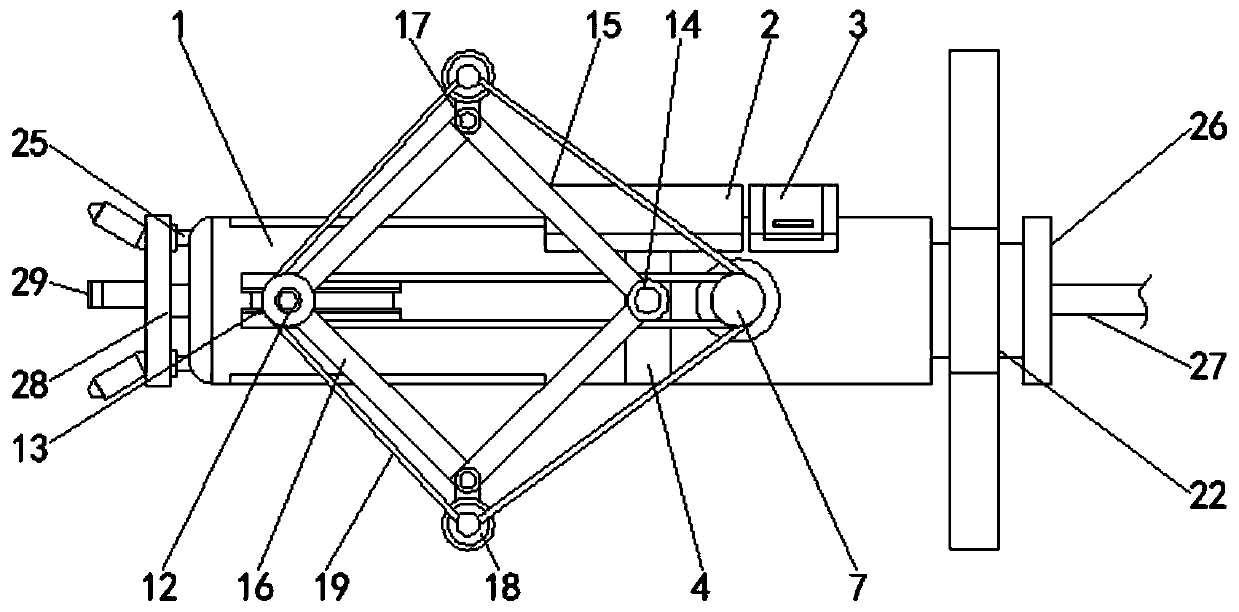

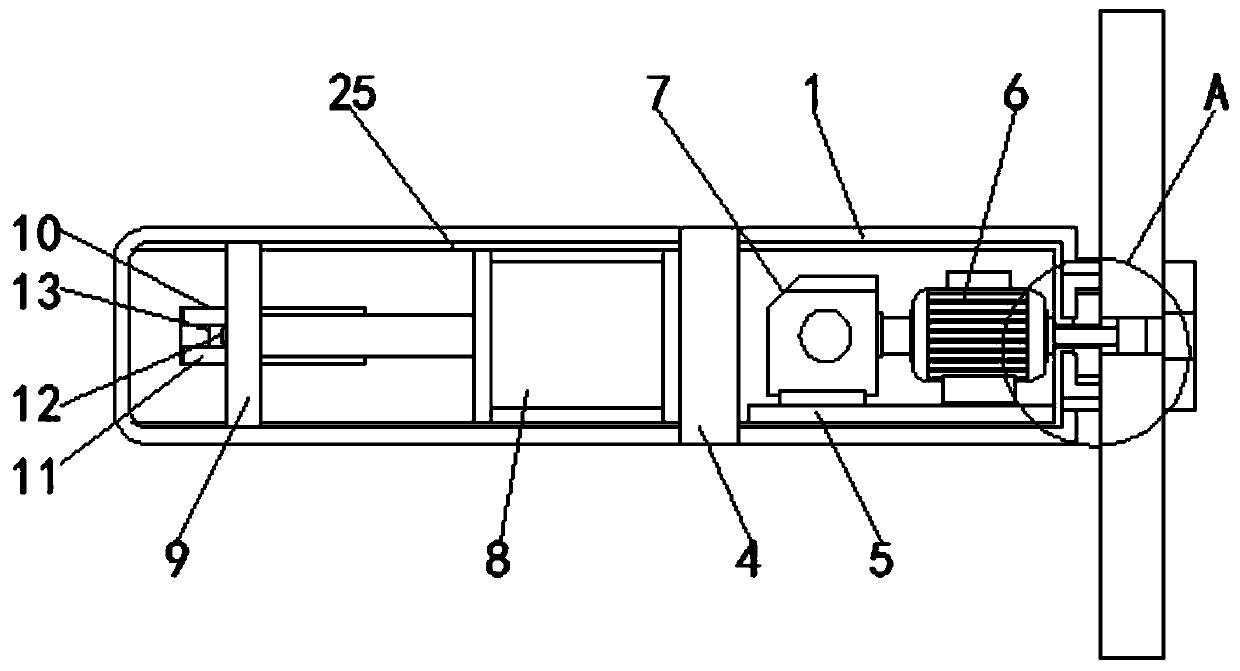

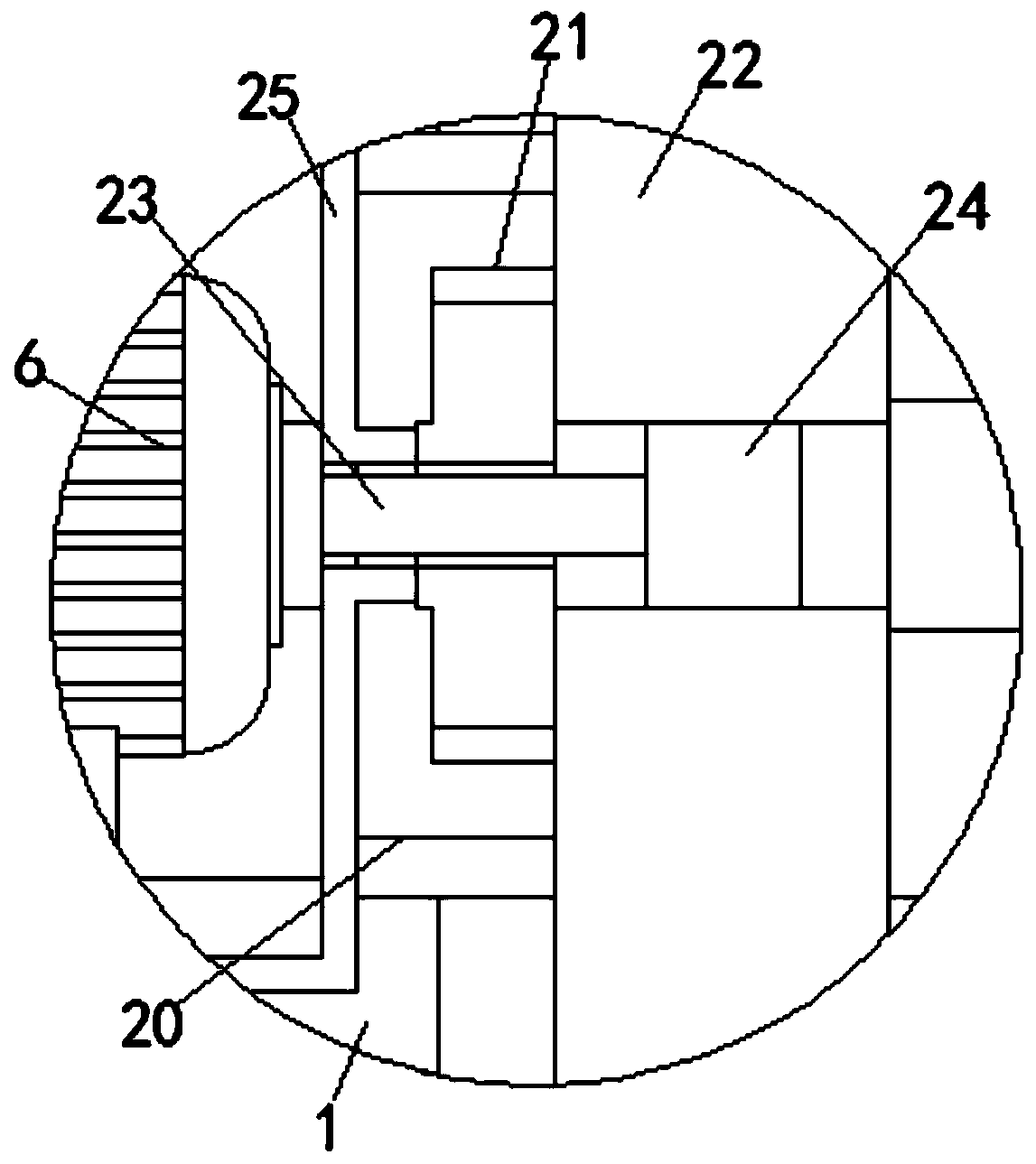

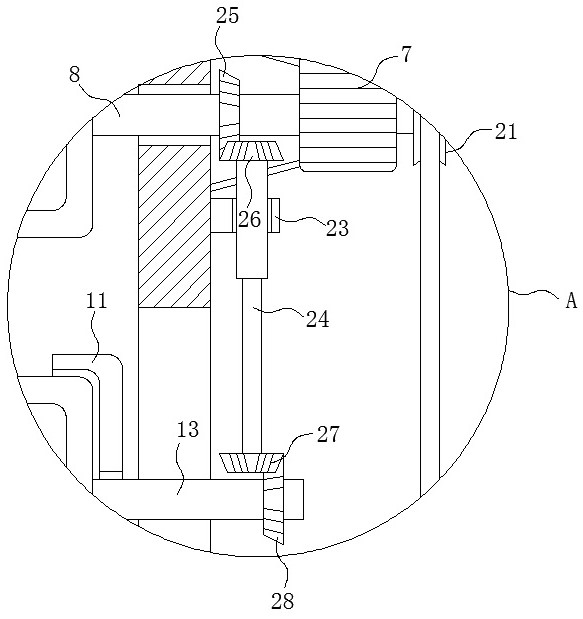

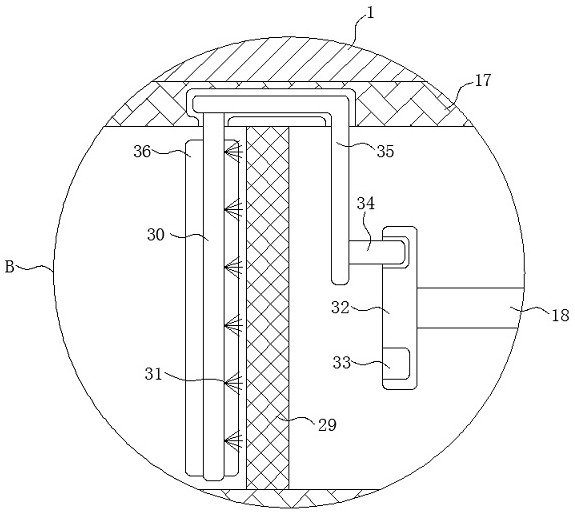

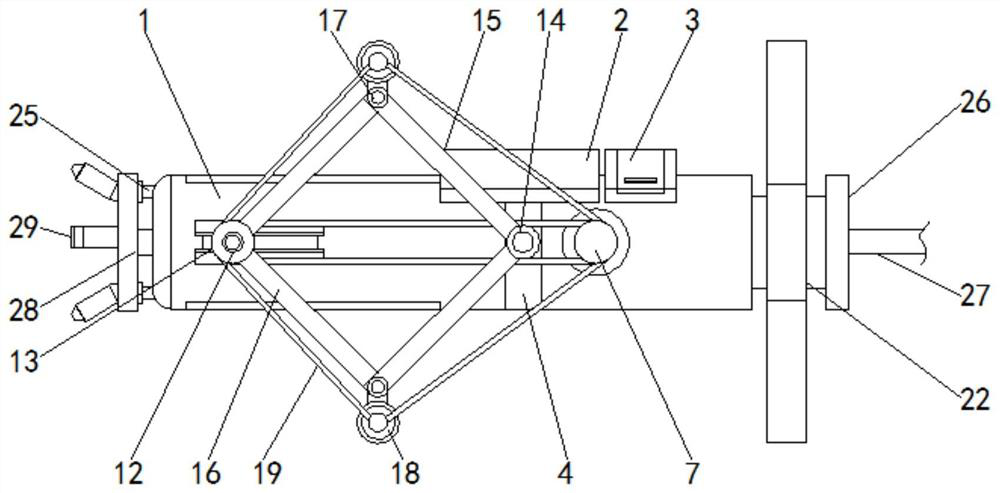

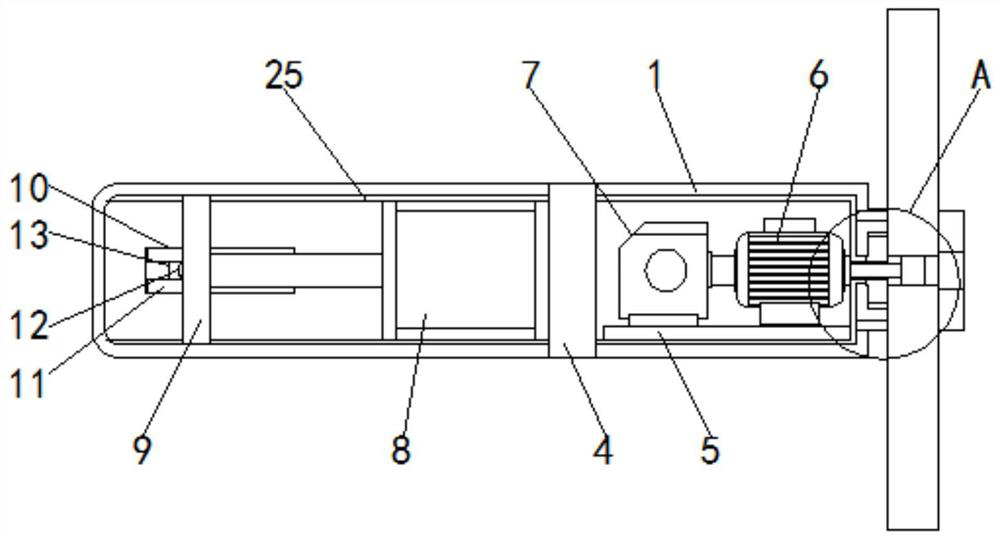

Self-spraying intelligent pipeline detecting dirt removing robot

ActiveCN111036631AReduce distanceHigh cleaning safety factorHollow article cleaningSprayerControl engineering

The invention relates to the technical field of pipeline robots, and discloses a self-spraying intelligent pipeline detecting dirt removing robot. A machine body is included. A controller is fixedly arranged on the top of the machine body. According to the self-spraying intelligent pipeline detecting dirt removing robot, an electric push rod is started corresponding to the pipeline caliber, a pushplate is pushed towards the left side of the machine body, a rotation rod is driven to move along a through hole, under the assistance of a hinge, an upper support arm and a lower support arm on theright side are pulled to get close to the middle, accordingly, the included angle between the upper support arm and the lower support arm on the upper side and the lower side is enlarged, the distancebetween two wheels is reduced, then, the wheels are attached to the pipe wall, and the machine body is plugged into a pipeline. Then, a double-output-shaft motor is started, a scraper is driven to rotate, the wheels are in transmission through a crawler belt and move along the pipe wall, a water conveying pipe is used for conveying water to a connecting disc, and the water enters an installing plate along a branch pipe and is finally sprayed to the pipe wall through a sprayer. The machine body moves the scraper to clean the sprayed and flushed pipe wall, and the purposes of pre-adjustment andthe high cleaning safety coefficient are achieved.

Owner:南通新森亚环保有限公司

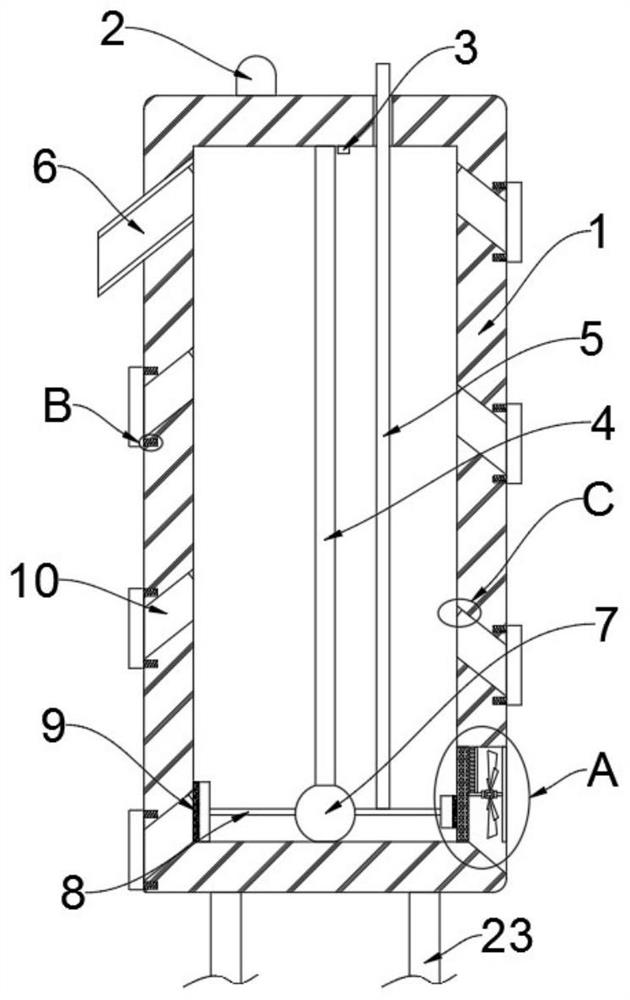

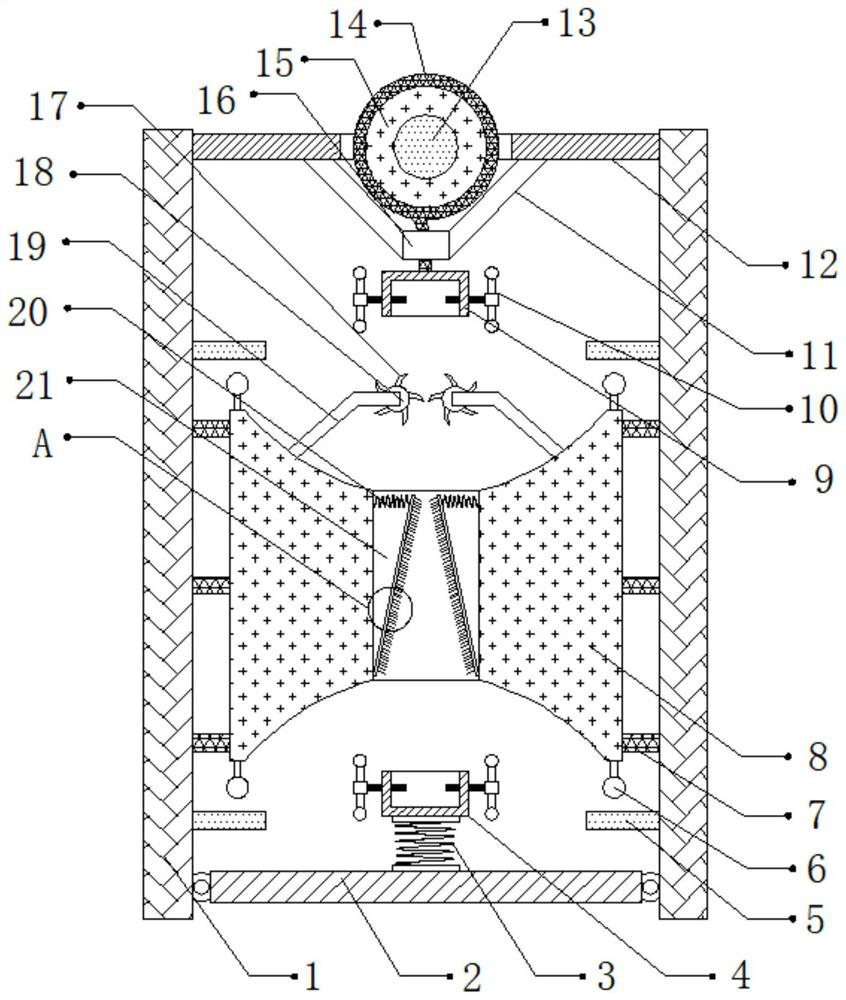

Sludge clearing equipment with anti-blocking function

InactiveCN112663712AWith anti-blocking functionCleanup impactSoil-shifting machines/dredgersFiltration separationSludgeDrive shaft

The invention relates to sludge clearing equipment with an anti-blocking function. The equipment comprises a collecting box and two floating plates, the collecting box is in a cuboid shape, the two floating plates are fixed to the two sides of the collecting box, an executing mechanism and an auxiliary mechanism are arranged on the collecting box, the executing mechanism comprises a power assembly and two executing assemblies, the power assembly comprises a driving motor, a transmission shaft, a screw rod, a fixed pipe, an auxiliary pipe and a driving bevel gear, each executing assembly comprises a driven bevel gear, a water pipe, a filter screen, a bearing, a rotating shaft, a connecting hole and a drainage hole, and the auxiliary mechanism comprises a sealing block, a moving ring, two transmission assemblies and two auxiliary assemblies. According to the sledge clearing equipment with the anti-blocking function, the sludge clearing function is achieved through the executing mechanism, in addition, the function of cutting off aquatic plants is achieved through the auxiliary mechanism, and the situation that sludge clearing is affected due to the fact that water inlet holes are blocked by the aquatic plants is prevented.

Owner:南京伊都锦环保科技有限公司

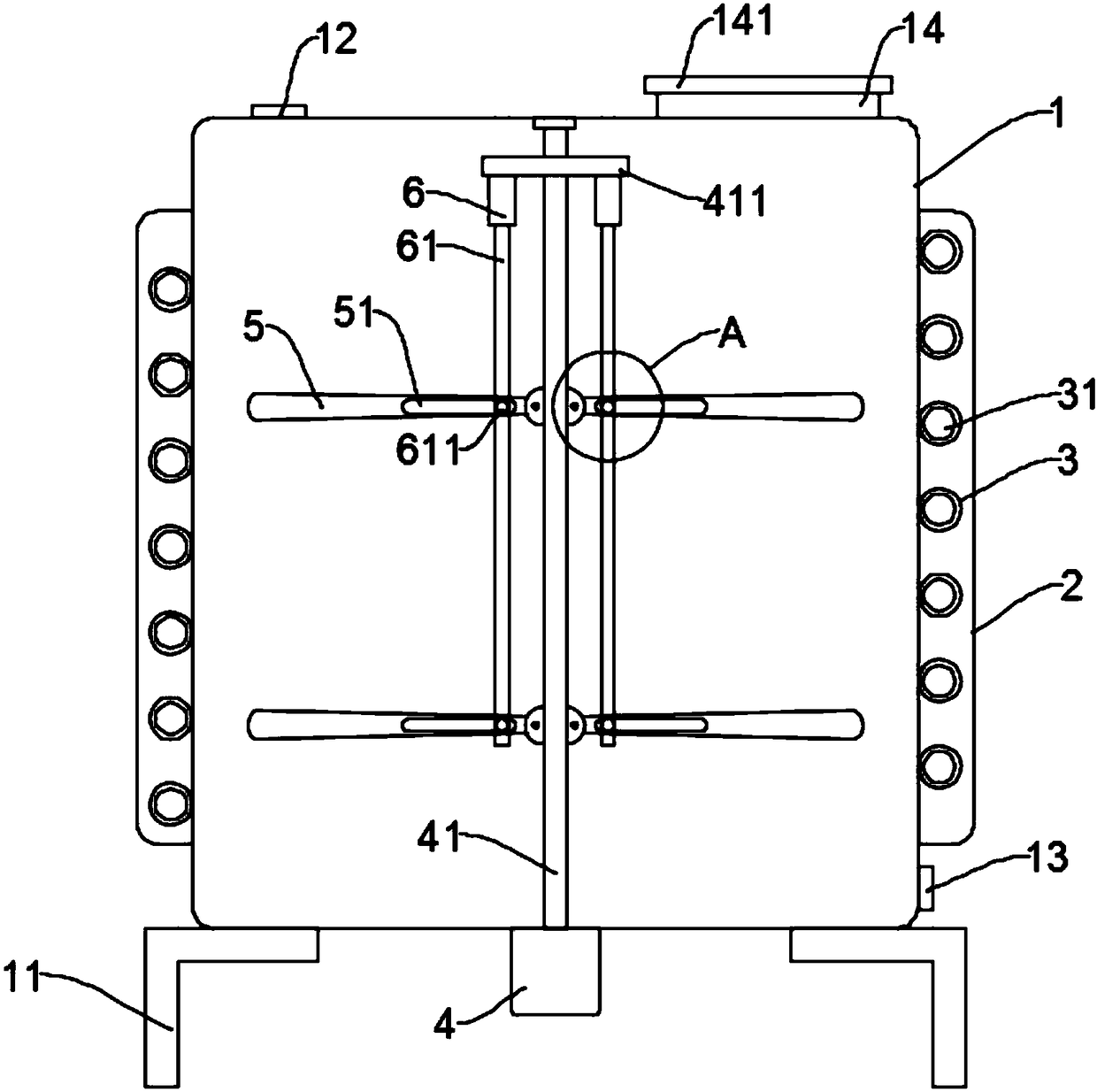

Chemical reaction tank for facilitating manual inner wall cleaning

PendingCN108212063AEvenly heatedSmall footprintChemical/physical/physico-chemical stationary reactorsChemical reactionChemical engineering

The invention discloses a chemical reaction tank for facilitating manual inner wall cleaning. The chemical reaction tank comprises a tank body, an outer cover body and a motor; the outer cover body isfixed on the periphery of the tank body, and a heating pipe is arranged in the outer cover body; the motor is installed at the center position of the bottom of the tank body, the output end of the motor is connected with a rotating shaft, the rotating shaft is provided with a plurality of sets of stirring blades, and each stirring blade is provided with a laterally-disposed waist-type hole; the periphery of the top shaft body of the rotating shaft is fixedly connected with a connecting plate, a telescopic device is installed on the bottom of the connecting plate, the movable end of the telescopic device is fixededly provided with telescopic rods, and the telescopic rods and the stirring blades are dislocated in a vertical direction. The side, near the stirring blade, of each telescopic rod is provided with a protruding column, and the protruding column is slidingly mounted in the waist-type hole in a clamping manner. The chemical reaction tank has the advantages of novel structure andconvenient operation, can effectively improve working efficiency, can retract the stirring blades to reduce the occupied space of the stirring blades, and avoids the influence of the stirring bladeson the manual inner wall cleaning.

Owner:章慧

Rapid soil removing device for earthworm breeding

InactiveCN112154978AQuick removalProcessing effectAnimal husbandryAgricultural scienceMechanical engineering

The invention relates to the technical field of earthworm breeding, and discloses a rapid soil removing device for earthworm breeding. The device comprises supporting legs, outer rods are arranged inside the supporting legs; an outer box is fixedly connected with the surfaces of the outer rods; and first leaking holes are formed in the surfaces of the outer box. According to the rapid soil removing device for earthworm breeding, a motor is started to drive a second concave gear to rotate, then a chain drives a first concave gear and a water pipe to rotate, then the water pipe is made to rotatereversely, meanwhile, a second gear drives a first gear to rotate, the outer rods and the outer box are made to rotate, and forward rotation is conducted. Therefore, earthworms can be conveniently separated from the soil, and the earthworms are processed, the soil of the earthworm processing process is reduced, so that bacterium breeding is prevented, the effect after cleaning is improved, the cleanness and tidiness of the earthworms are guaranteed, and the influence on later processing of the earthworms due to incomplete cleaning is avoided.

Owner:李延平

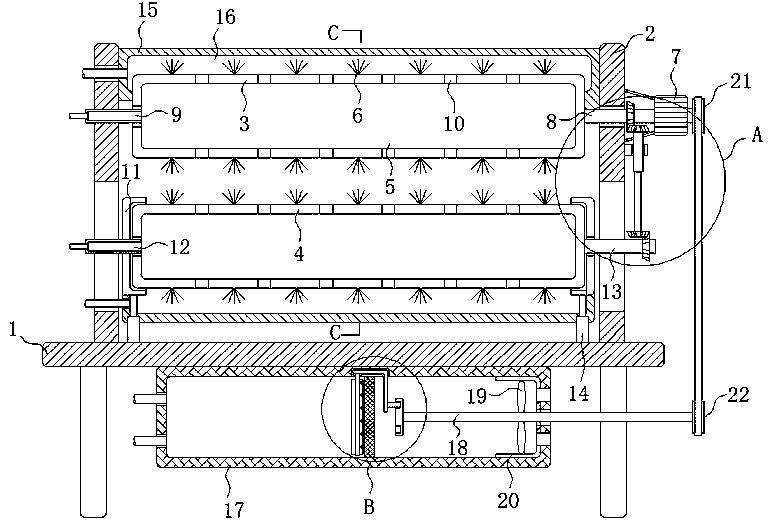

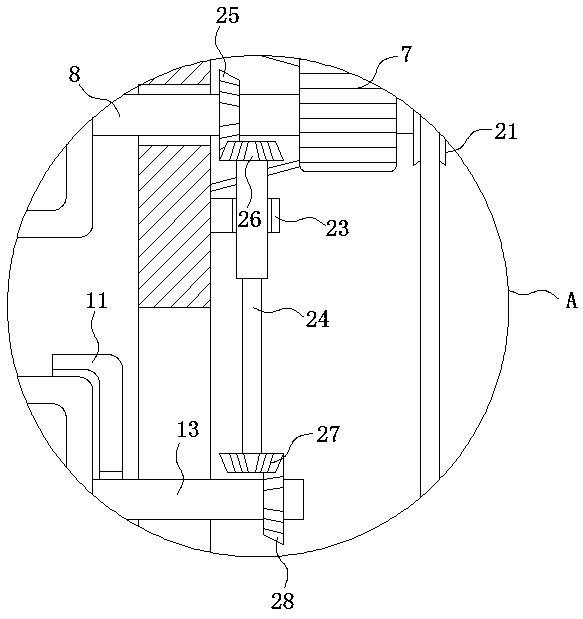

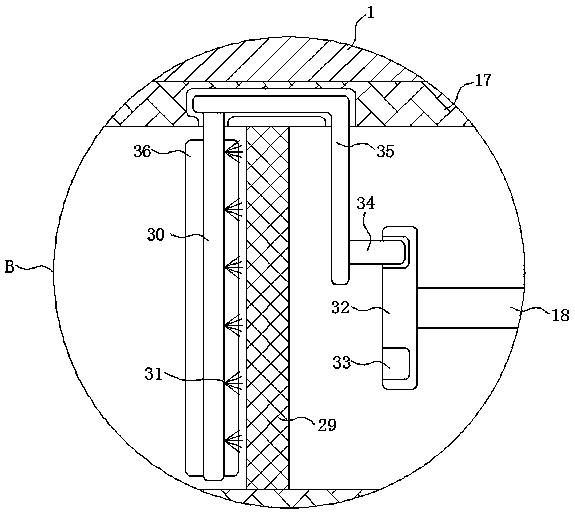

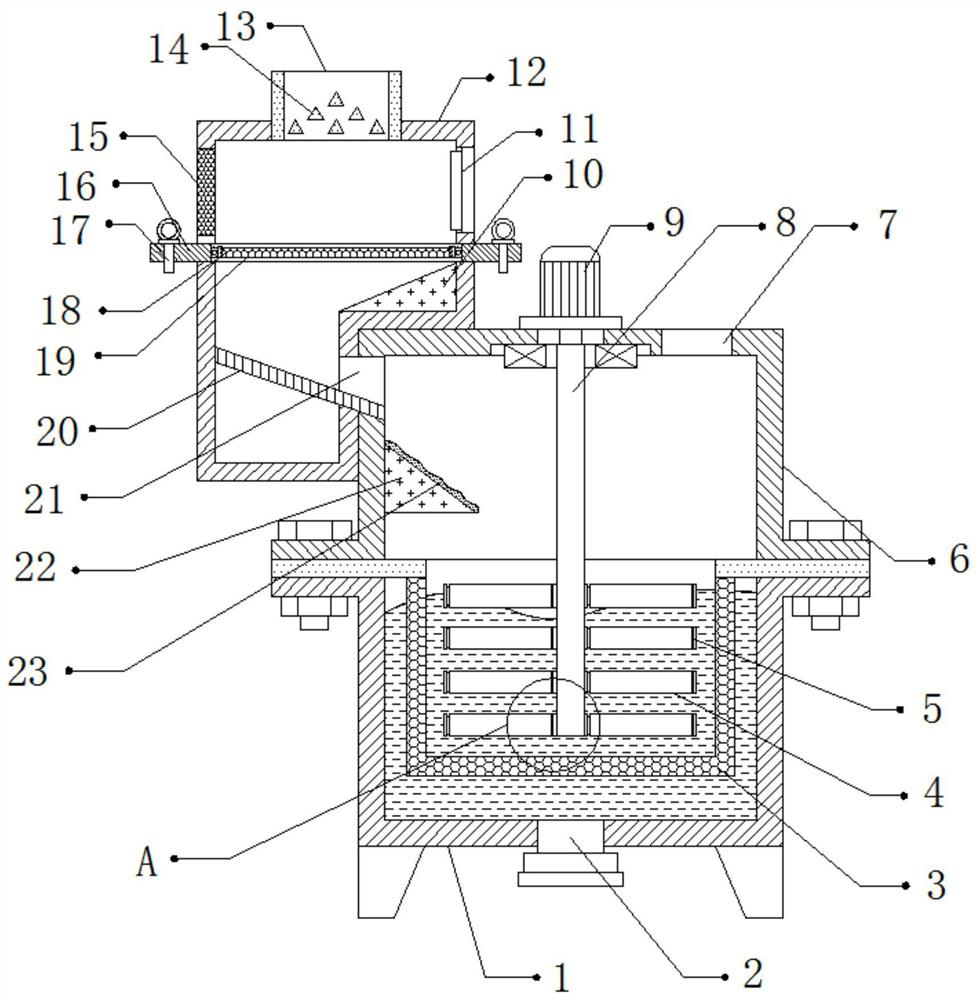

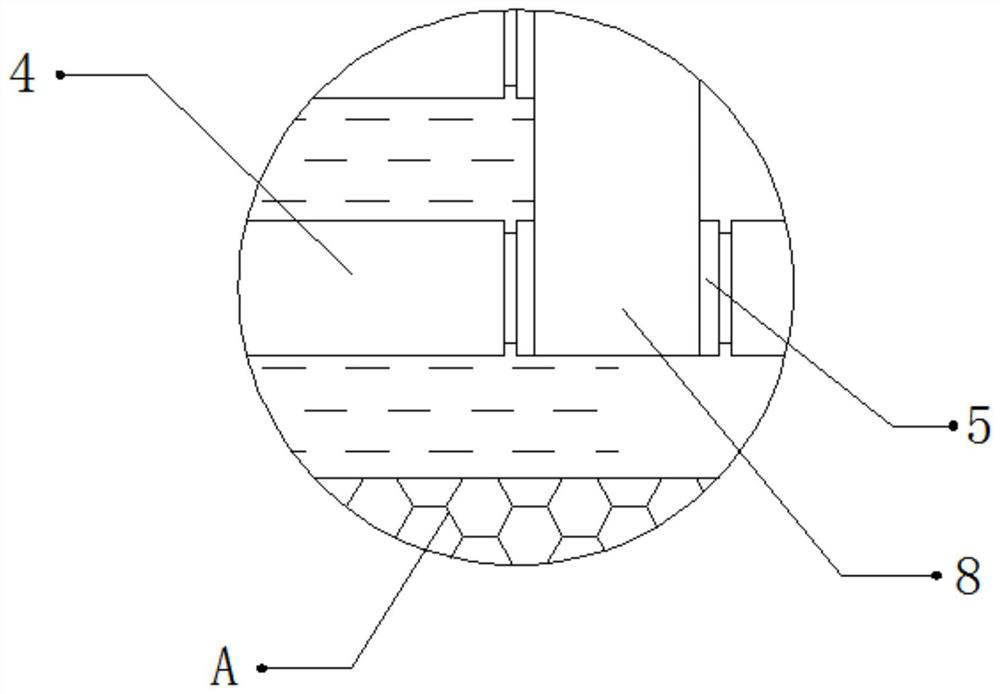

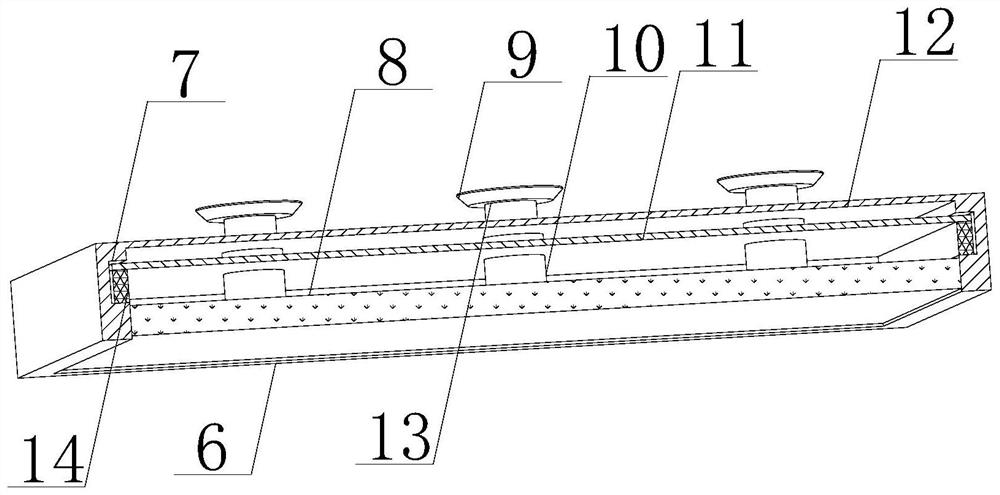

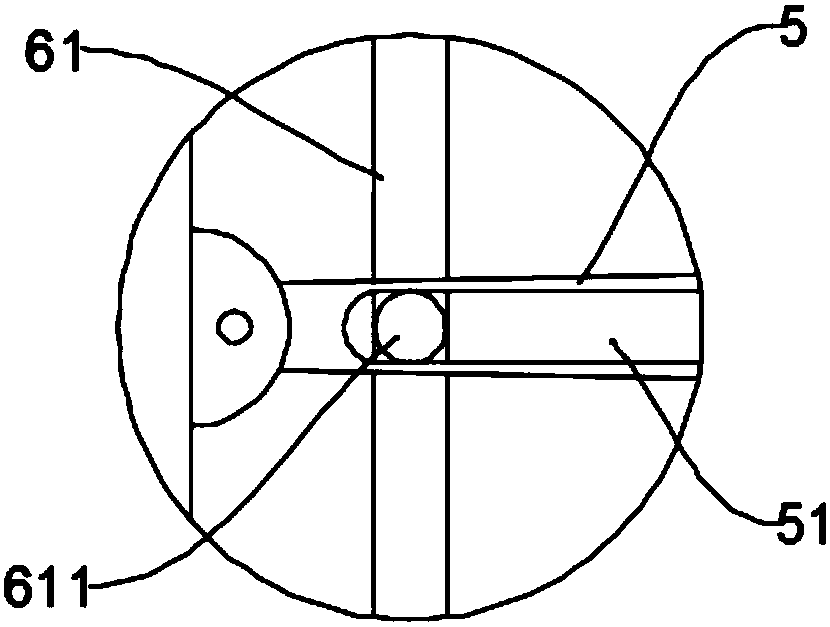

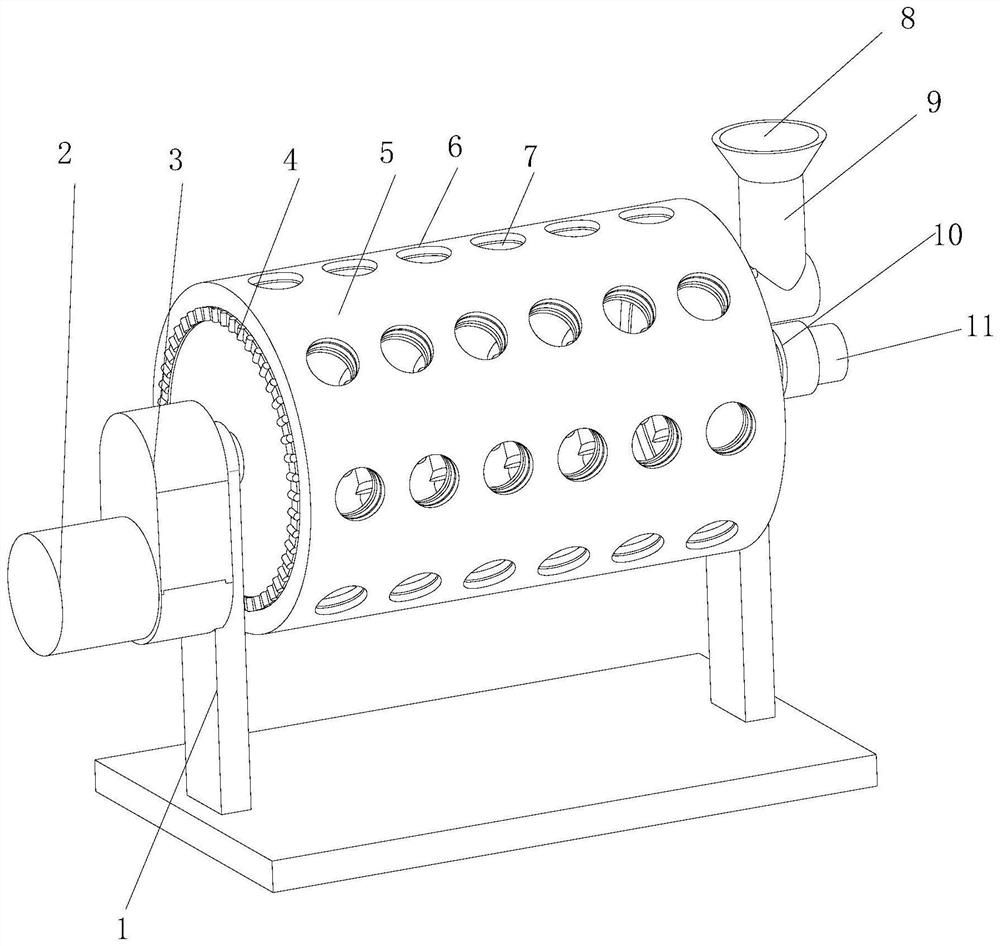

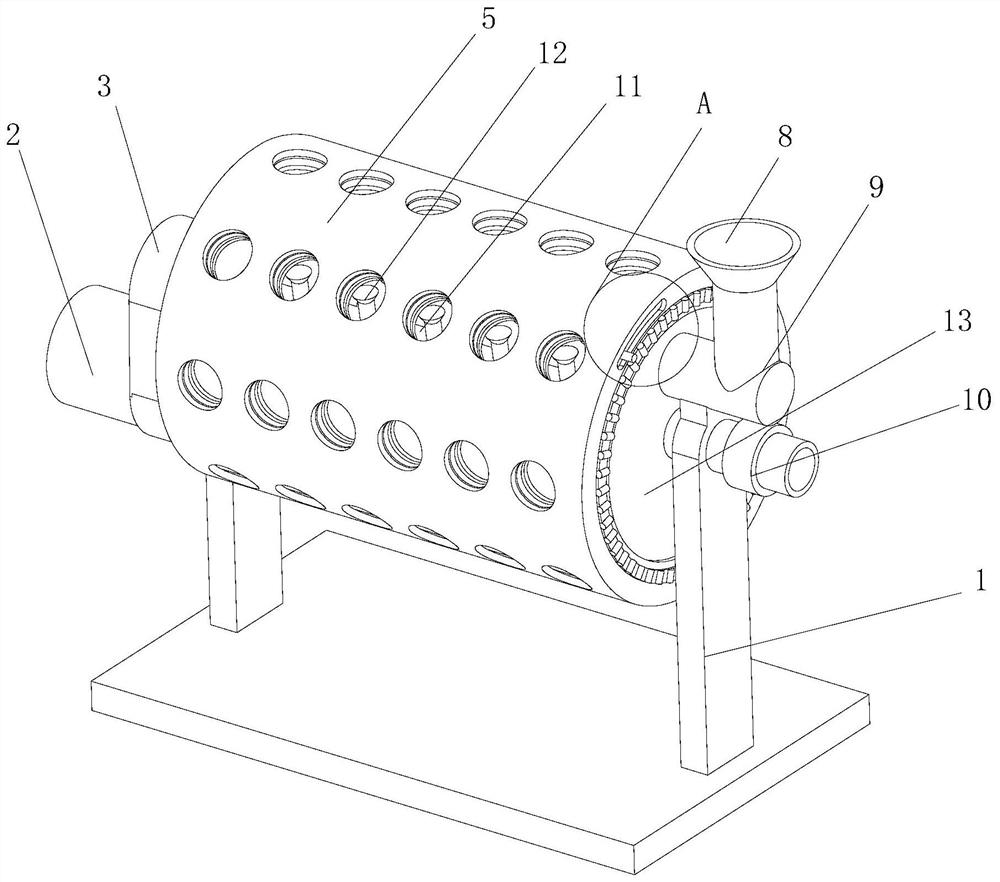

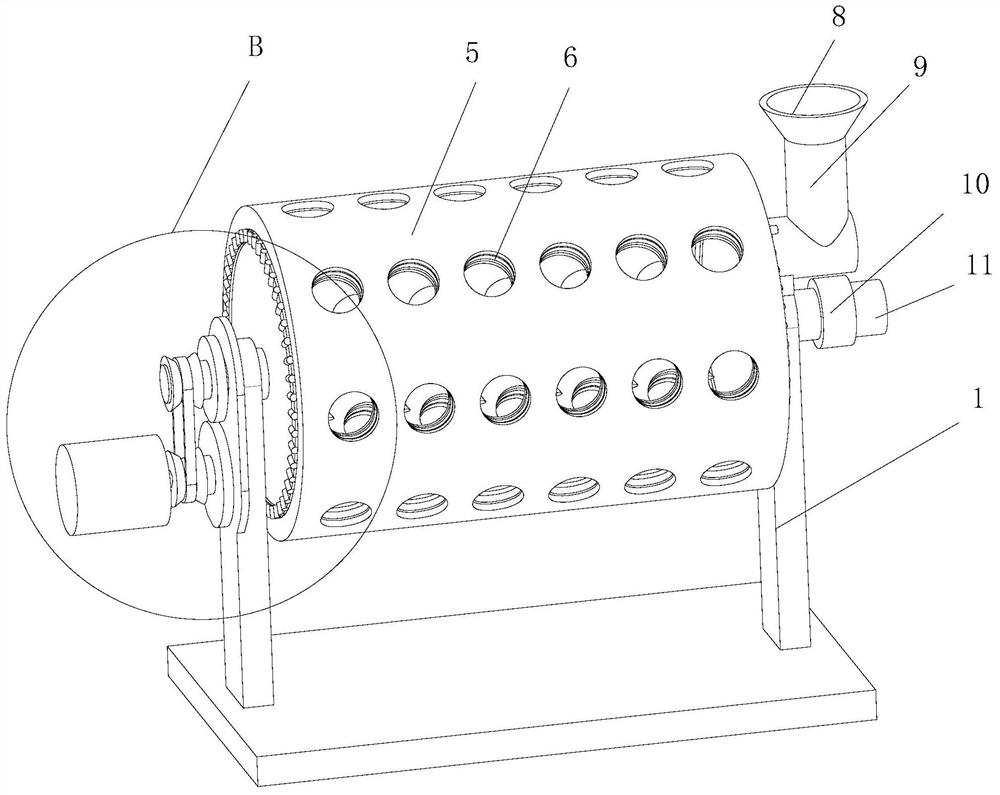

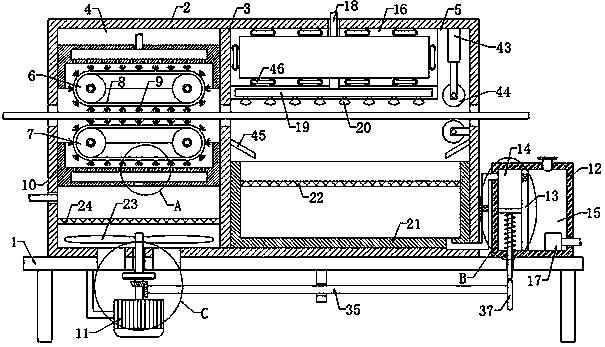

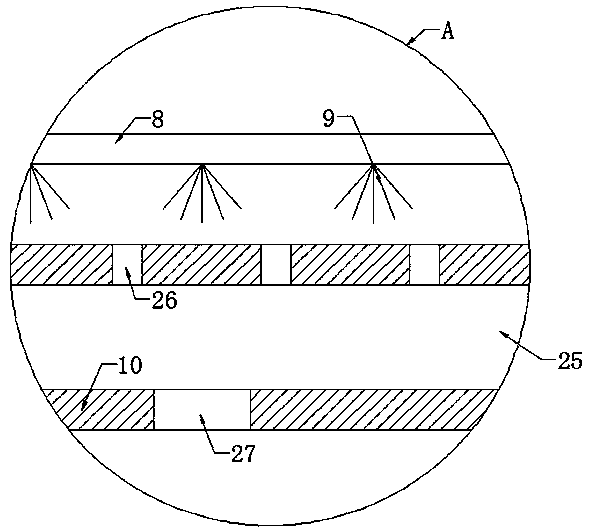

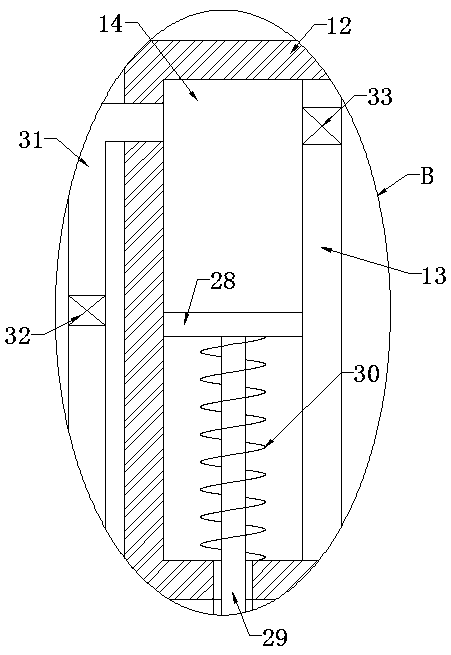

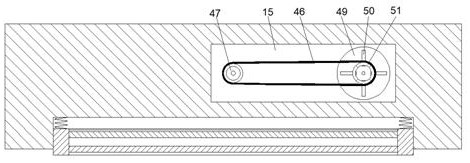

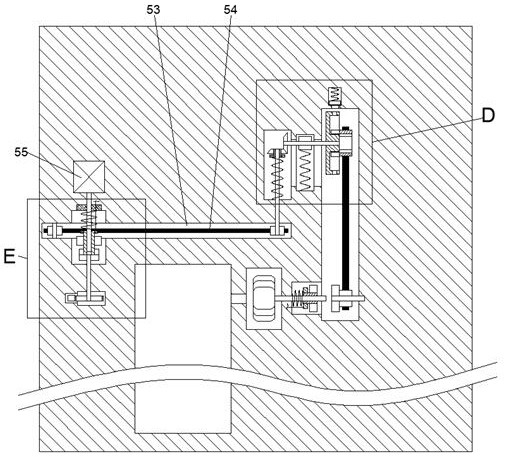

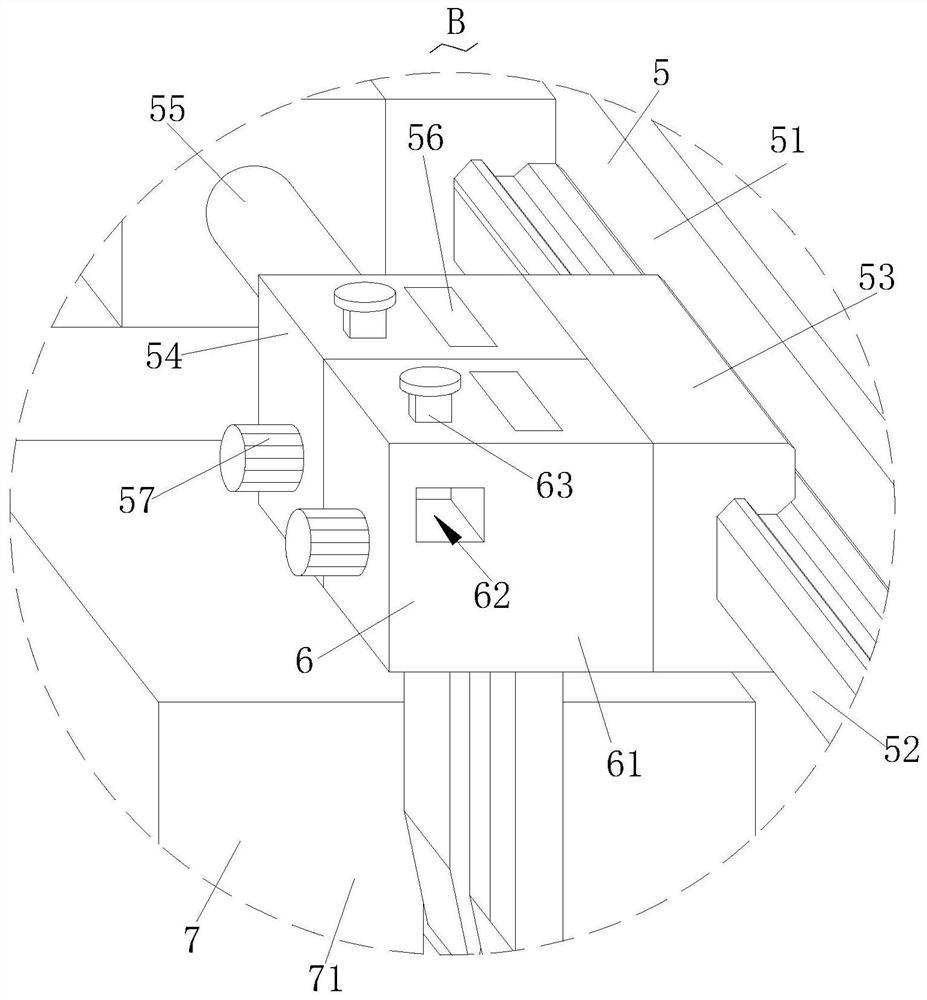

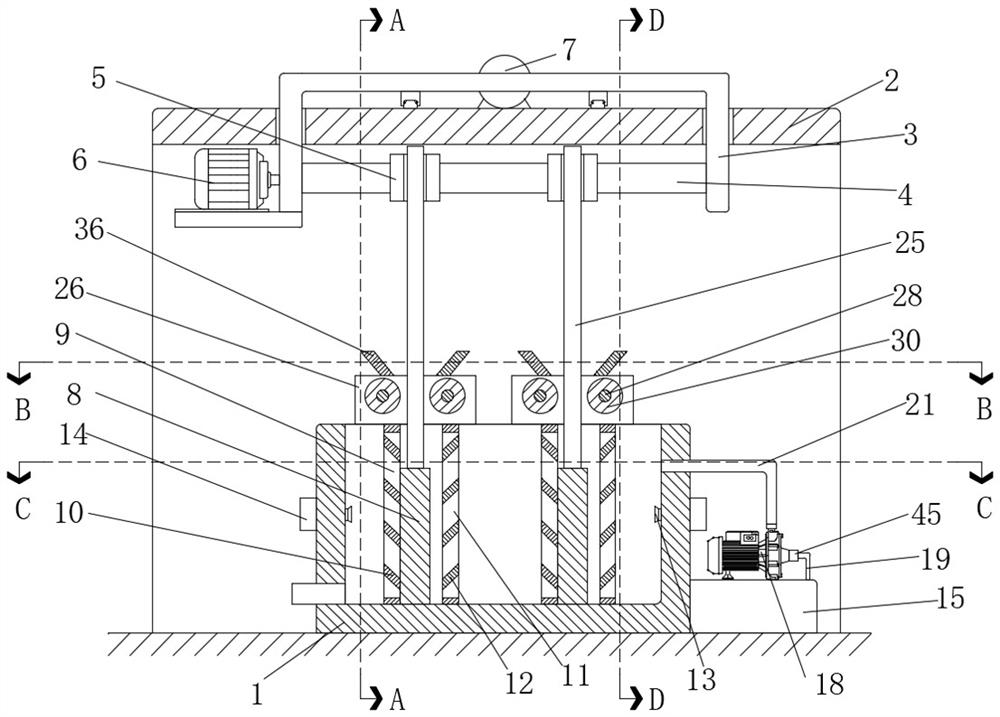

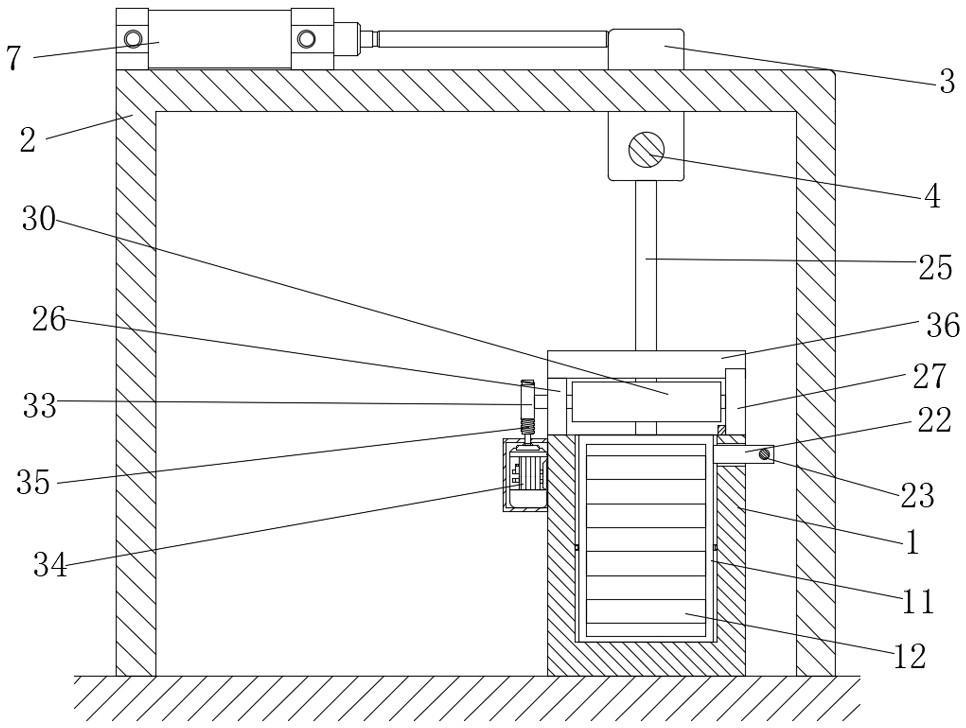

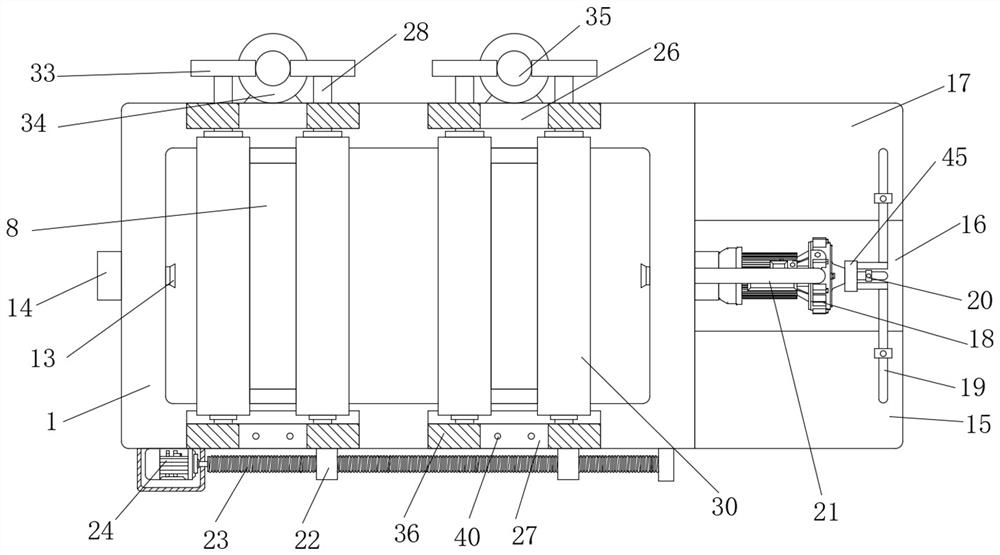

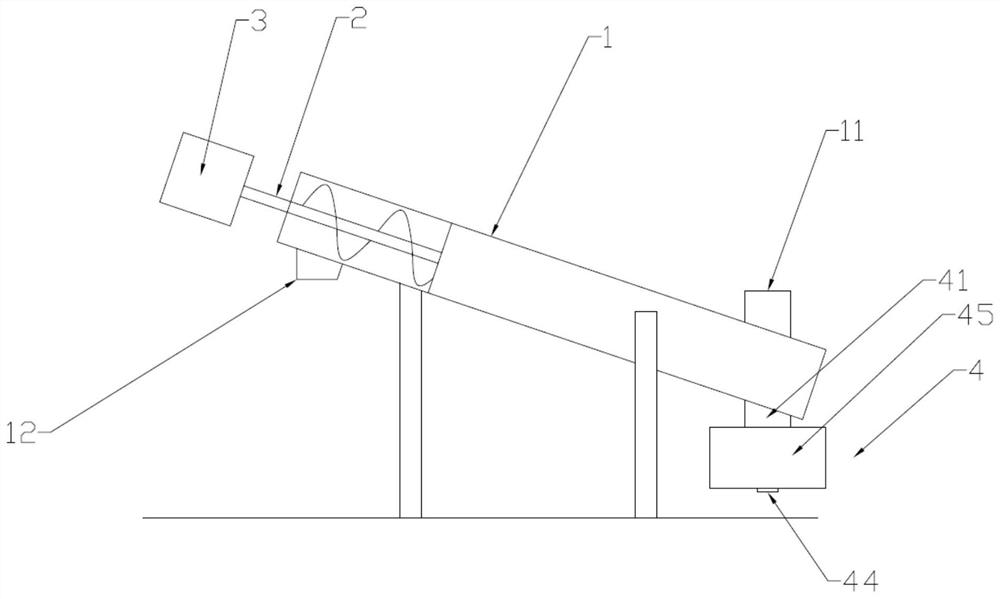

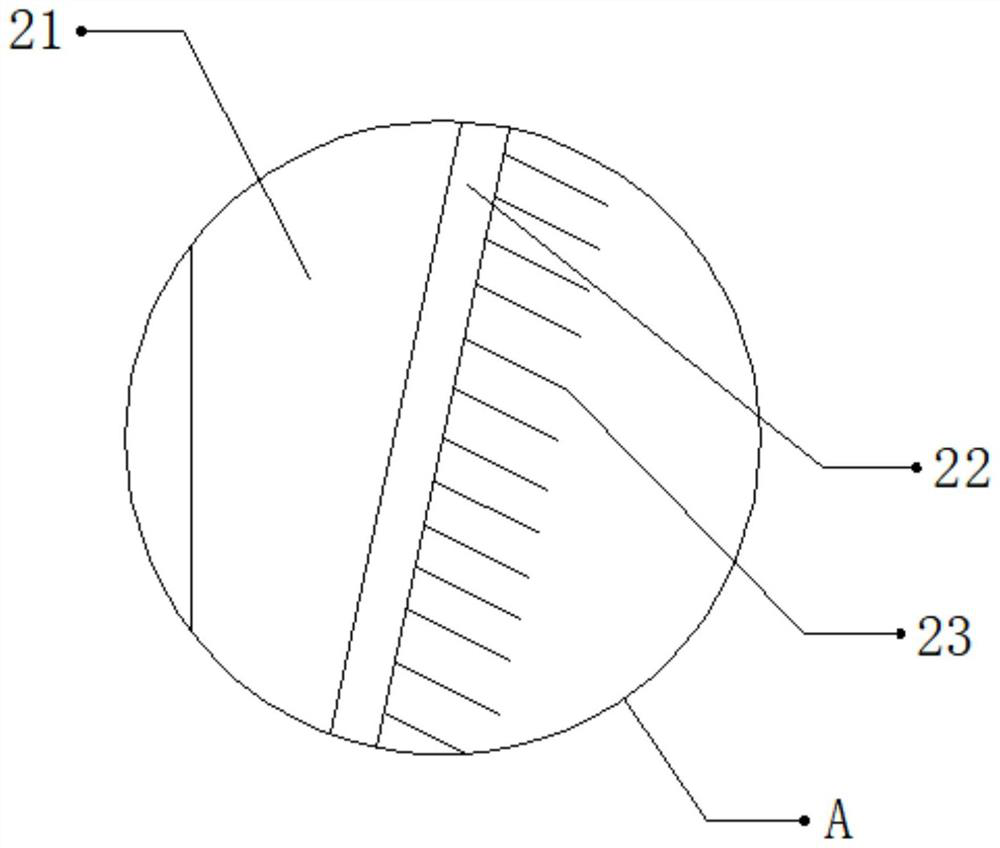

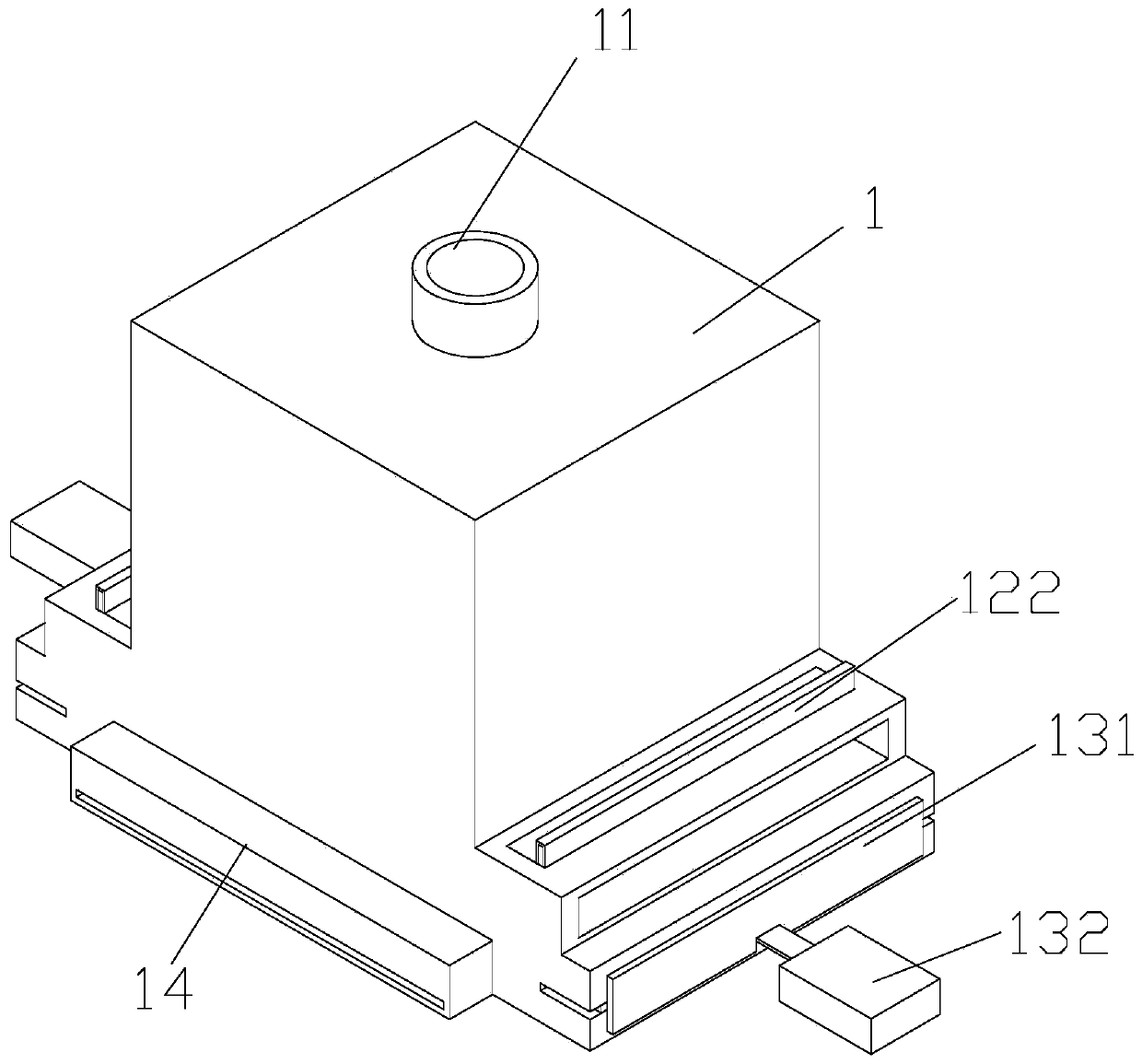

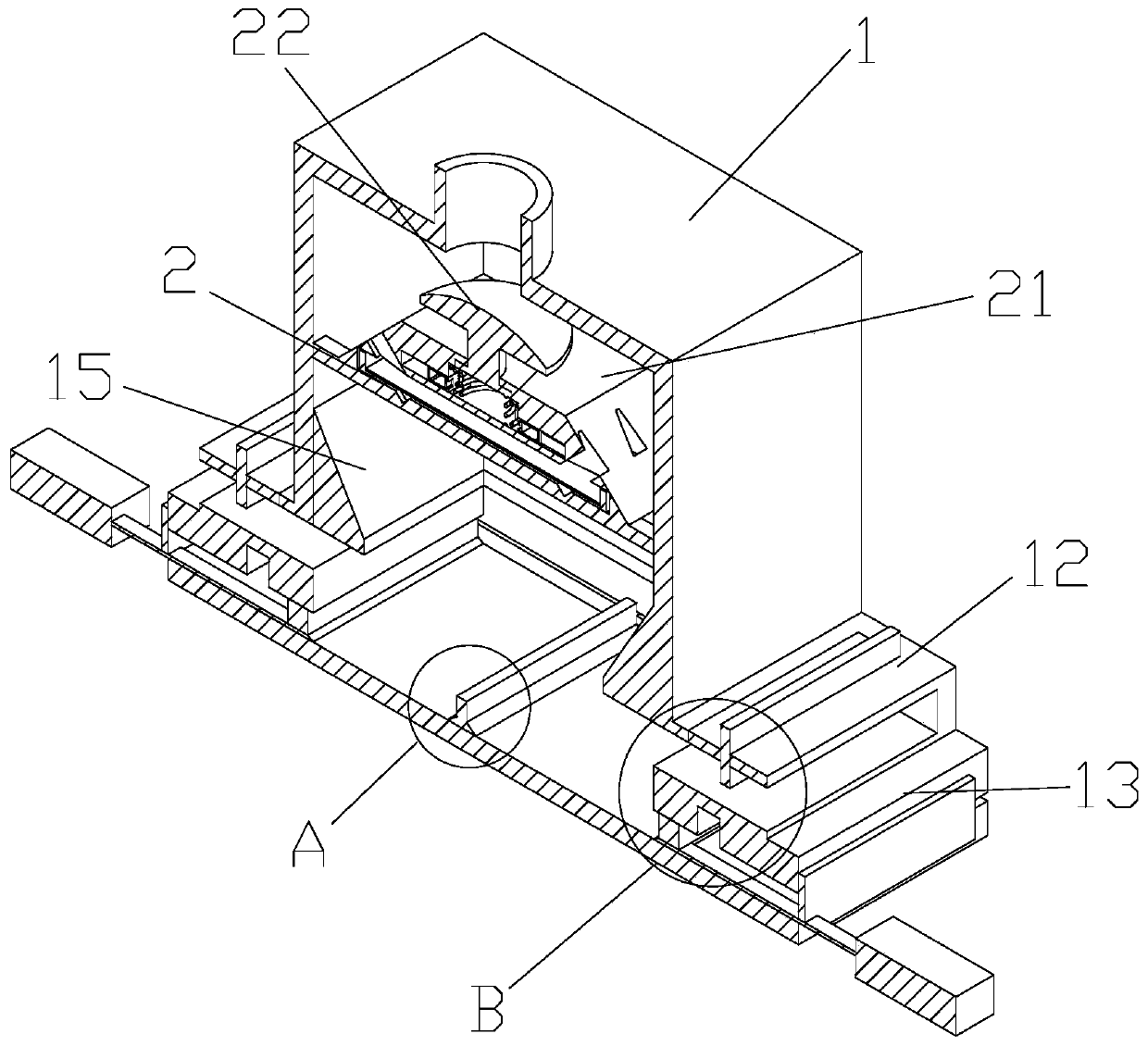

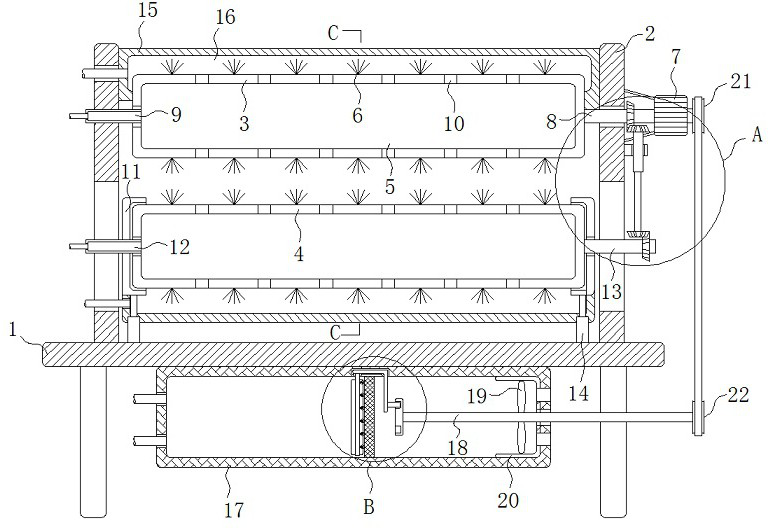

Uniform sizing and shaping equipment for textile yarns

InactiveCN111334951ACleanup impactReduce labor intensityLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingBristleTextile yarn

The invention discloses uniform sizing and shaping equipment for textile yarns. The equipment comprises a box body fixedly connected to the upper end of a base, wherein the inner wall of the box bodyis fixedly connected with a partition plate which divides the inside of the box body into a cleaning chamber and a sizing chamber; the upper end of the base is fixedly connected with a sealing box; the inner wall of the sealing box is fixedly connected with a vertical plate; the vertical plate divides the inner wall of the sealing box into a sliding plug chamber and a liquid storage chamber; the inner top of the sizing chamber is fixedly connected with a liquid discharge box; and the inner bottom of the liquid storage chamber is fixedly connected with a water pump. A negative pressure impellerrotates so that a position under the cleaning chamber is in a negative pressure state, burrs and impurities on bristles are further adsorbed through a dust collection pipe; the influence caused by contamination of the bristles on the cleaning of the impurities on the yarns is avoided; a sliding plug performs vertically reciprocating movement on the inner wall of the sliding plug chamber through the rotation of a cam and intermittent collision with the lower end of a vertical rod; a slurry in a liquid collection frame is pumped into the liquid storage chamber; and the slurry in the liquid collection frame can be recycled.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

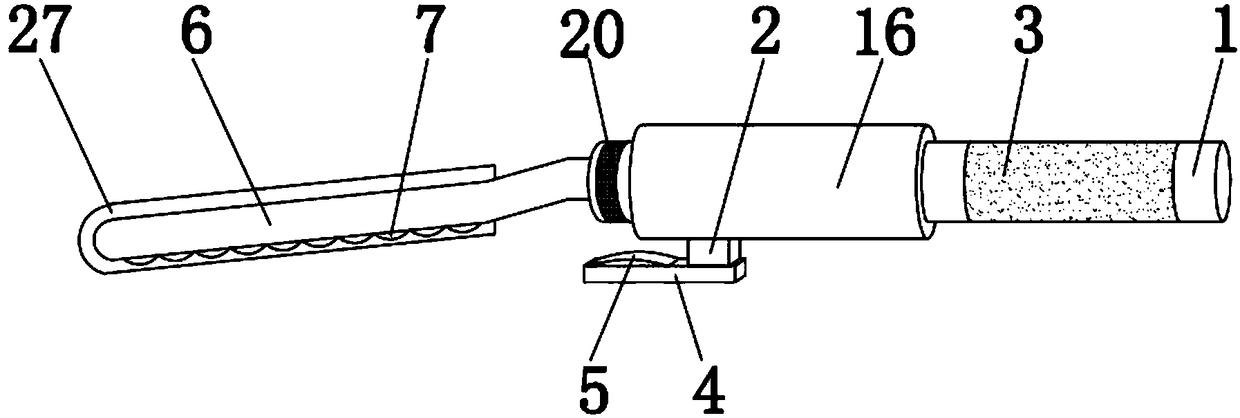

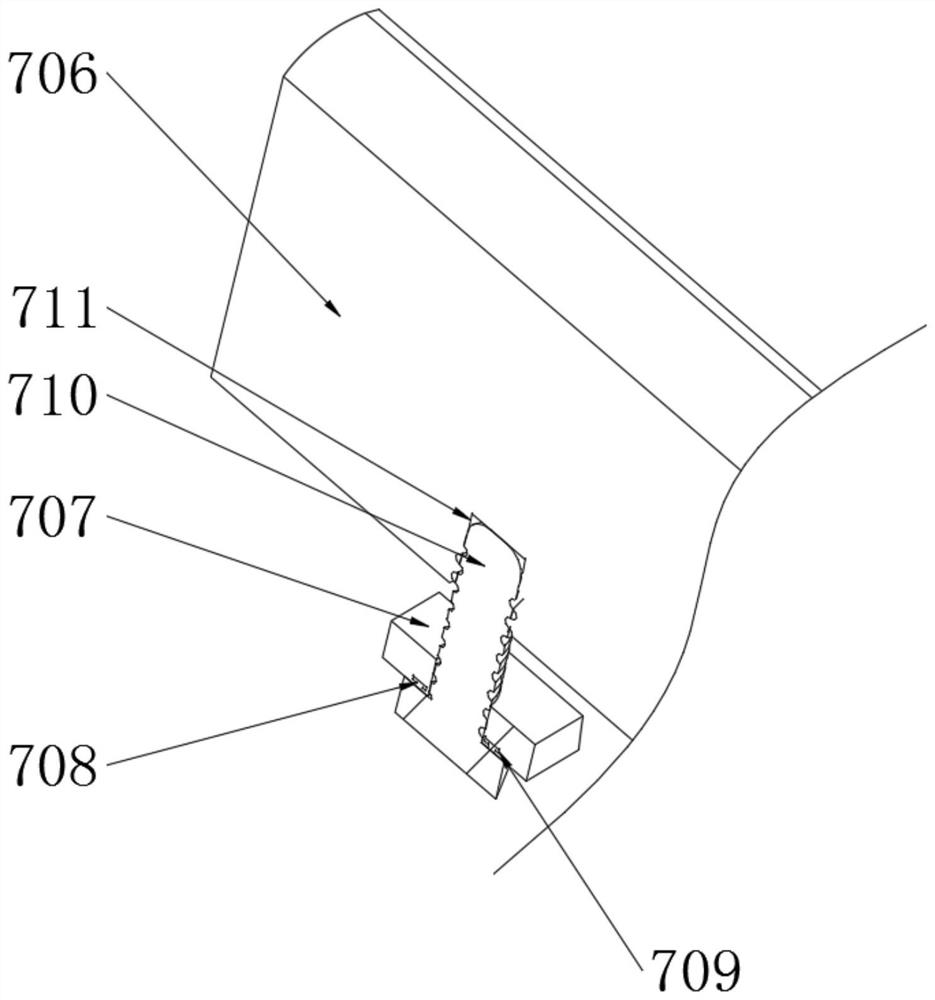

Conveniently-cleaned bone file used for orthopedics department

The invention discloses a conveniently-cleaned bone file used for the orthopedics department. The bone file comprises a transverse rod. The left side of the transverse rod is equipped with a file rod.The bottom end of the pile rod is equipped with pile teeth. The left side on the outer wall of the transverse rod is equipped with a sleeve pipe. Upper and right ends on the left side of the sleeve pipe are both provided with sliding rods. The right sides at the upper and lower ends of the outer wall of the transverse rod are equipped with baffle plates. Sliding grooves are connected with slidingrods through sliding blocks. Connection blocks are driven by carrying a pipe sleeve to move. The connection blocks move to drive a transverse plate. The pile teeth of the pile rod coincide through acotton pad so that shattered bones generated when the pile teeth pile bones are cleaned effectively. Therefore, the bone-piling effect is not affected because bones of a solid body are timely filed. Through elastic force of second compression springs, shattered bones on the pile teeth are cleaned. Additionally, the bone file is convenient to use and is simple in structure and high in practicability. The conveniently-cleaned bone file is operated in a labor-saving manner. Additionally, an application demand of a user is met.

Owner:叶忠伟

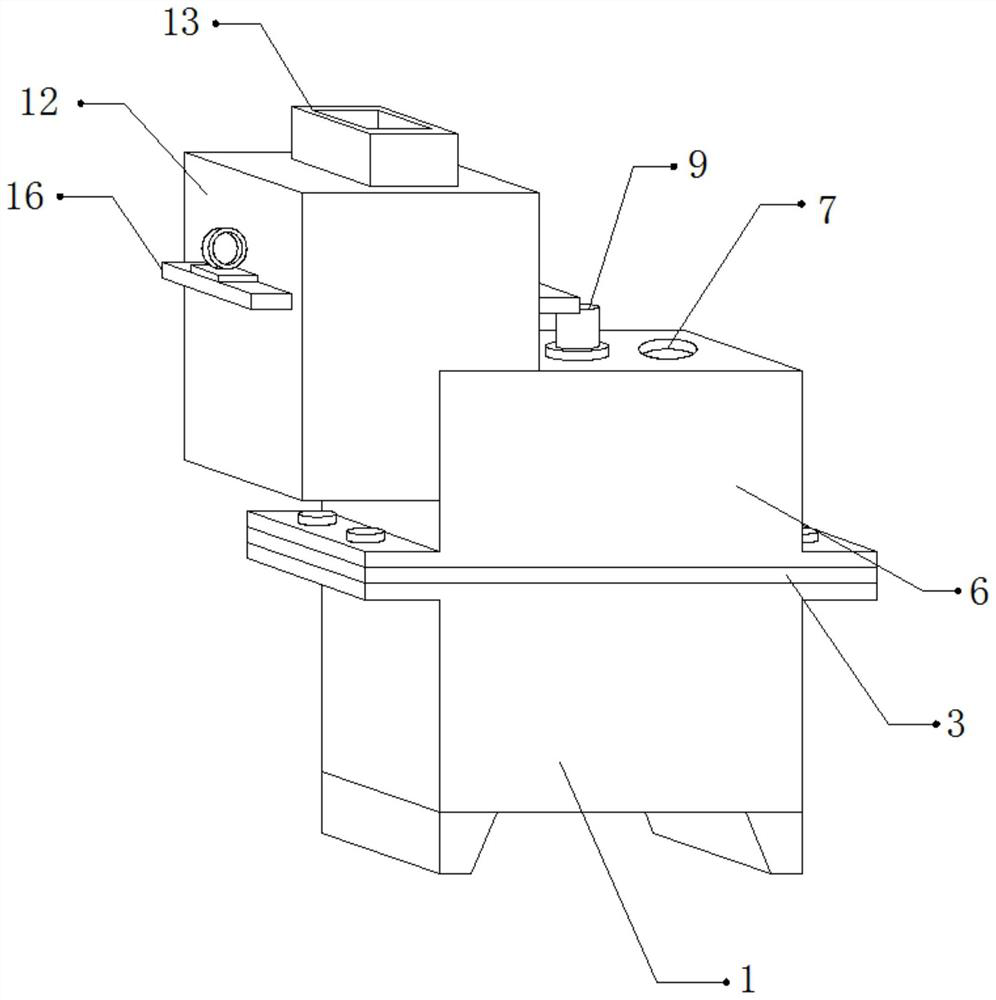

Efficient automatic cutting machine for metal square and rectangular pipes

ActiveCN114669796AAvoid damageReduce lateral frictionTube shearing machinesMaintainance and safety accessoriesStructural engineeringIndustrial engineering

The efficient metal square and rectangular pipe automatic cutting machine comprises a base, a containing groove is formed in the center axis of the top of the base, and a plurality of small holes are formed in the outer wall of the top of the containing groove. According to the efficient automatic cutting machine for the metal square and rectangular pipes, when a rectangular pipe is cut by a cutting blade, vibration can be generated, extrusion rods on the two sides can transversely move due to vibration, and an arc-shaped gas pipe can drive friction cleaning balls to transversely move back and forth under the effect of transverse movement of the extrusion rods; the friction cleaning ball is in clearance contact with the cutter face of the cutting blade in the transverse movement process, under the contact effect, waste chips adsorbed on the cutting blade can be cleaned, and the situation that a large number of waste chips are adsorbed on the cutting blade and the cutting effect is affected is prevented; in this way, the transverse friction force between the cutting blade and the friction cleaning ball can be reduced, and the cutting blade is prevented from being damaged.

Owner:博恩德智能装备(江苏)有限公司

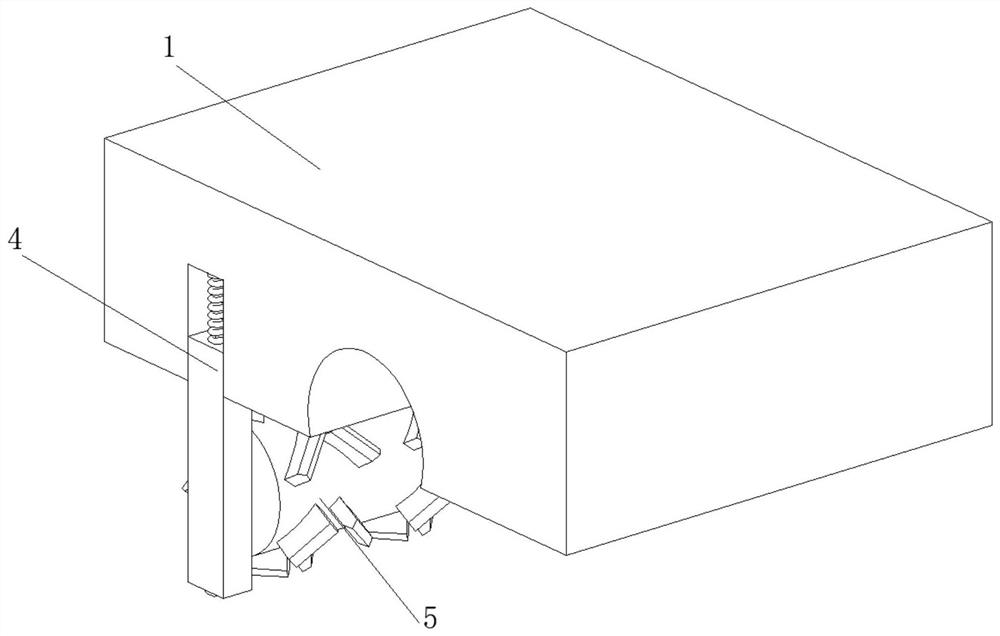

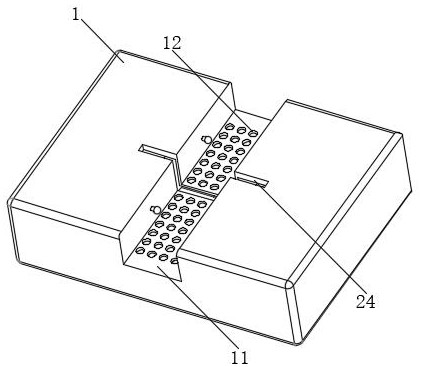

DIY toy model bottom plate cleaning equipment

InactiveCN113426733AImprove cleaning qualityCleanup impactCleaning using toolsCleaning using liquidsMechanical engineeringEngineering

Owner:JIAN CRAB KINGDOM TECH CO LTD

Q420 zinc plating degreasing and iron removing device and using method thereof

ActiveCN113275278AFixed connection releaseEasy to replaceCleaning using toolsCleaning using liquidsOil and greaseFixed frame

The invention discloses a Q420 zinc plating degreasing and iron removing device and a using method thereof. The Q420 zinc plating degreasing and iron removing device provides the following scheme that the Q420 zinc plating degreasing and iron removing device comprises a cleaning box, two symmetrical plates are arranged in the cleaning box, a moving assembly used for moving the plates is arranged above the cleaning box, the top of the cleaning box is provided with two sets of symmetrical cleaning assemblies used for conducting preliminary cleaning on the surface layers of the plates, and the interior of the cleaning box is provided with two sets of symmetrical scraping assemblies used for conducting oil stain and iron powder scraping on the surface layers of the plates. The Q420 zinc plating degreasing and iron removing device is simple in structure and convenient to operate, through mutual cooperation of a fixed frame and a sliding plate, oil stains and iron powder on the surface layers of the plates can be scraped away, the surface layers of the plates can be cleaned in advance through a steel brush wheel before the plates enter the cleaning box, degreasing and iron removal can be conveniently conducted on the plates in the later period, in addition, the steel brush wheel can be replaced regularly, and the influence of excessive grease and iron powder accumulated in the steel brush wheel on later-stage pre-cleaning of the plates is prevented.

Owner:宜兴大平杆塔制造有限公司

Self-cleaning hair scraping device

The invention relates to the related field of cosmetic instruments, and discloses a self-cleaning hair scraping device which comprises a main box body, a scraper base sliding cavity with a downward opening is formed in the main box body, a scraper base is connected into the scraper base sliding cavity in a sliding fit mode, and a blade cavity penetrating up and down is formed in the scraper base; scraper base springs in bilateral symmetry are fixedly connected between the upper end face of the scraper base and the upper end wall of the scraper base sliding cavity, in the hair scraping process of the device, suction force generated on the surface of a filter screen can adsorb scraped hair, the subsequent cleaning process is reduced, great convenience is brought to use of a user, and meanwhile, a water pump is rotated to enable water flow to flush a blade cavity from inside to outside after being pressurized, hair in the blade cavity can be quickly and cleanly cleaned, the situation that the next use is affected due to the fact that the hair and scurf remaining on the scraper blade breed bacteria is avoided, and moreover, the water consumption in a water storage cavity can be automatically adjusted according to the hair scraping amount, so that consumption of water resources is reduced.

Owner:义乌市鼎程贸易有限公司

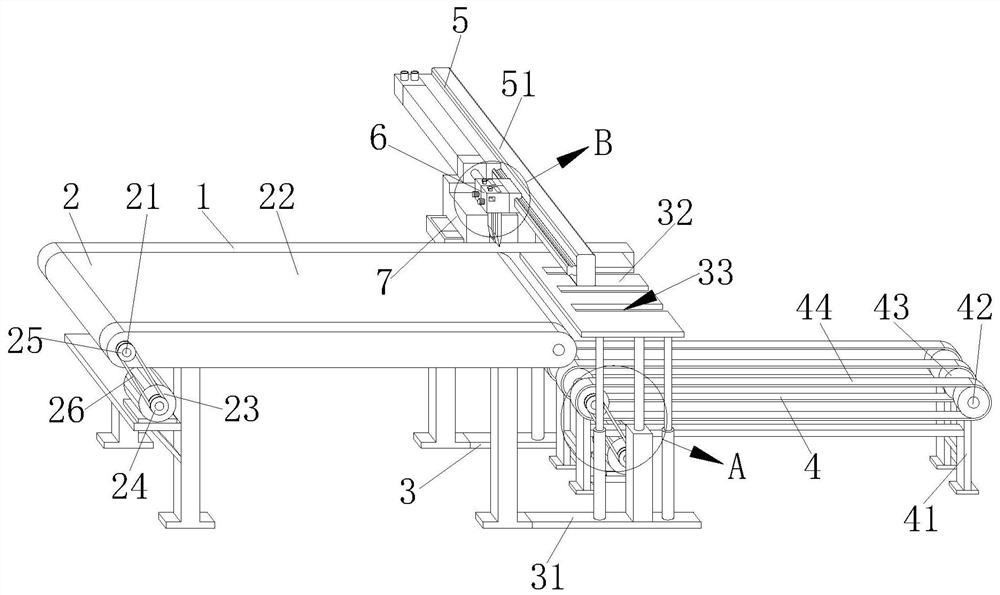

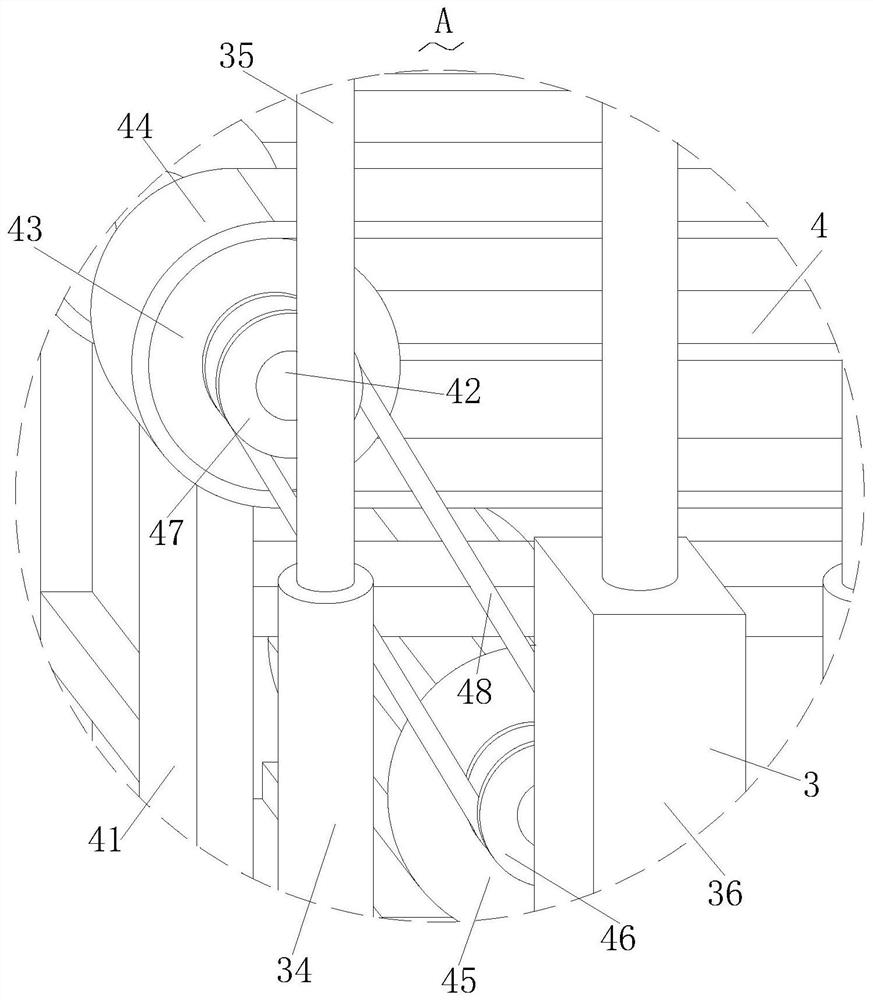

Glass tape production device

InactiveCN112723730AImprove feeding efficiency and safetyImprove unloading efficiencyGlass severing apparatusFixed frameTool bit

The invention relates to the field of glass tape production devices, and particularly discloses a glass tape production device. The device comprises a fixing frame, a first conveying structure, a material receiving structure, a second conveying structure, a cutting structure, a slitting structure and a cleaning structure. The arrangement of the first conveying structure can automatically and continuously convey the glass tape, manual feeding is not needed, the feeding efficiency and safety can be greatly improved, the arrangement of the material receiving structure is matched, automatic discharging is conducted after the glass tape is cut into small pieces of glass, manual discharging is not needed, the discharging efficiency can be improved, and the discharging safety is improved. The second conveying structure is arranged, so that the glass on the material receiving structure can be automatically conveyed after the material receiving structure automatically descends, the automatic conveying efficiency can be improved, the distances between the pieces of placed glass can be equal, subsequent processing of the blocky glass is facilitated, and the production efficiency is improved. And through the cutting structure, the glass cutting tool bit can be quickly mounted and replaced.

Owner:秦志千

A q420 galvanized degreasing and iron removal device and its application method

ActiveCN113275278BFixed connection releaseEasy to replaceCleaning using toolsCleaning using liquidsIron powderIron removal

The invention discloses a Q420 galvanized degreasing and iron removal device and its use method. The following scheme is proposed now, which includes a cleaning box. Two symmetrical plates are arranged in the cleaning box. As for the moving assembly of the moving plate, two sets of symmetrical cleaning components for preliminary cleaning of the surface of the plate are arranged on the top of the cleaning box, and two sets of symmetrical cleaning components for cleaning the surface of the plate are arranged inside the cleaning box. Scraping assembly for scraping off oil stains and iron powder. The invention has simple structure and convenient operation. The oil stain and iron powder on the surface of the plate can be scraped off through the cooperation of the fixed frame and the sliding plate, and the steel brush passes through the plate before entering the cleaning box The wheel can pre-clean the surface of the plate, which is convenient for degreasing and iron removal of the plate in the later stage. In addition, the steel brush wheel can be replaced regularly to prevent excessive grease and iron powder accumulated in the steel brush wheel from affecting the pre-cleaning of the plate in the later stage.

Owner:宜兴大平杆塔制造有限公司

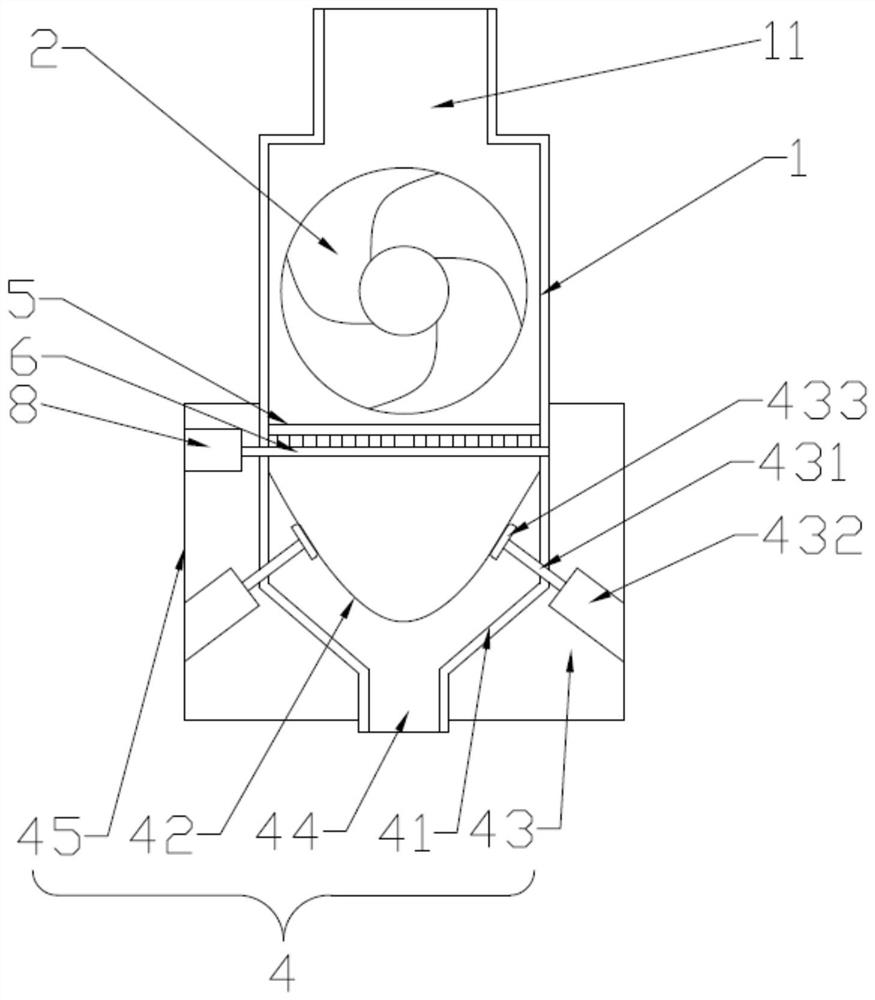

Cleanable ventilator protective net

InactiveCN110296108AAvoid enteringClean up in timePump componentsTunnel/mines ventillationBristleEngineering

The invention belongs to the field of ventilation equipment for mining, and relates to a cleanable ventilator protective net. The cleanable ventilator protective net comprises a ventilator body. A horn-shaped opening is formed in an air inlet of the ventilator body. A primary protective net is arranged at the end of the horn-shaped opening, a support is arranged at the upper end of the horn-shapedopening, a pneumatic cylinder is fixed to the support, the pneumatic cylinder is connected with a time relay, a cleaning brush is connected to the end of a piston rod of the pneumatic cylinder, bristles of the cleaning brush make contact with the primary protective net, and the cleaning brush is obliquely arranged; the primary protective net is a long-strip type net. The protective net is reasonable in structural design, impurities can be prevented from entering a ventilator, normal work of the ventilator is effectively ensured, fresh air is supplied under the shaft in time, the ventilator body is protected, and the service life of the ventilator is prolonged.

Owner:ZIBO HUAYUAN MINING CO LTD

A quick release hinge

The invention discloses a quick-detachable hinge, which comprises a first cylinder, a second cylinder is arranged on the right side of the first cylinder, and the upper and lower sides of the first cylinder and the second cylinder are respectively equipped with fixed mechanism, the fixing mechanism includes a connecting rod connected with the first cylinder and the second cylinder, a fixing plate is installed on the connecting rod, a fixing hole is opened on the fixing plate, and a fixing hole is installed on the right side of the second cylinder. ring, and limit braces are installed on the fixed ring. The invention provides a quick-detachable hinge with ingenious structure and reasonable layout. The design of the ball reduces the friction force when the first cylinder and the second cylinder contact and rotate, so that the door rotates more smoothly and smoothly. Convenient, the first cylinder and the second cylinder made of metal are always in contact with each other through the magnet, so as to avoid the situation that the gap fixed by the limit brace is too large, causing the overturned object such as the door to be displaced and affecting the normal use.

Owner:安徽华安六和家居科技有限公司

An energy-saving and environment-friendly heat exchanger with high thermal efficiency

ActiveCN111609737BEasy to useEasy maintenanceCorrosion preventionHeat exhanger sealing arrangementMechanical engineeringThermal efficiency

The invention discloses an energy-saving and environment-friendly heat exchanger with high thermal efficiency. The top is bonded with a sealing rubber rod, the two ends of the top surface of the shell are provided with corresponding circular arc grooves corresponding to the circular arc plates, the front of the shell cover is provided with corresponding baffle grooves corresponding to the deflector baffles, and the outer two ends of the shell are at the bottom of the tension plate Both ends are welded with mounting blocks, and the bottom surface of the mounting block is provided with a snap-in arc groove. Through the cooperation of the shell cover, shell, handle and tensioning screw, it is convenient for the staff to check and repair the original parts inside the shell, without the need for the staff to carry out the entire heat exchange. Disassembly of the device improves the working efficiency of the staff and improves the safety factor of the staff, saving maintenance time. Through the use of the arc plate, the arc rubber rod, the rubber rod and the sealing groove, the gap between the shell and the shell cover Sealed and fixed, convenient for users to use.

Owner:荣成市鹏达电子有限公司

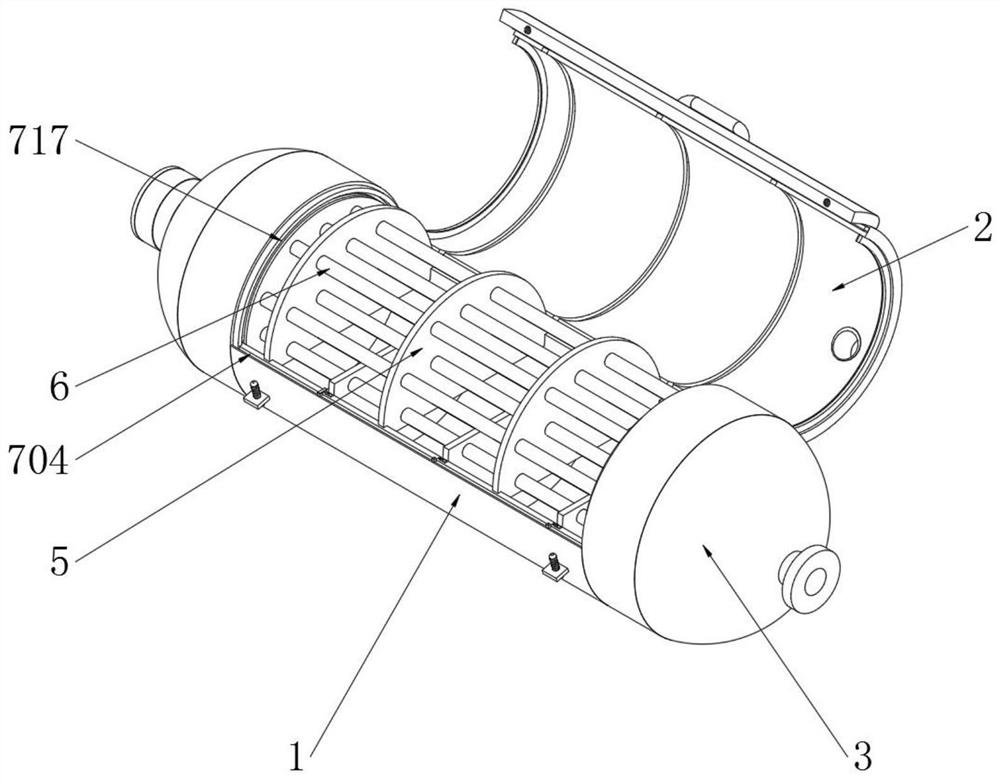

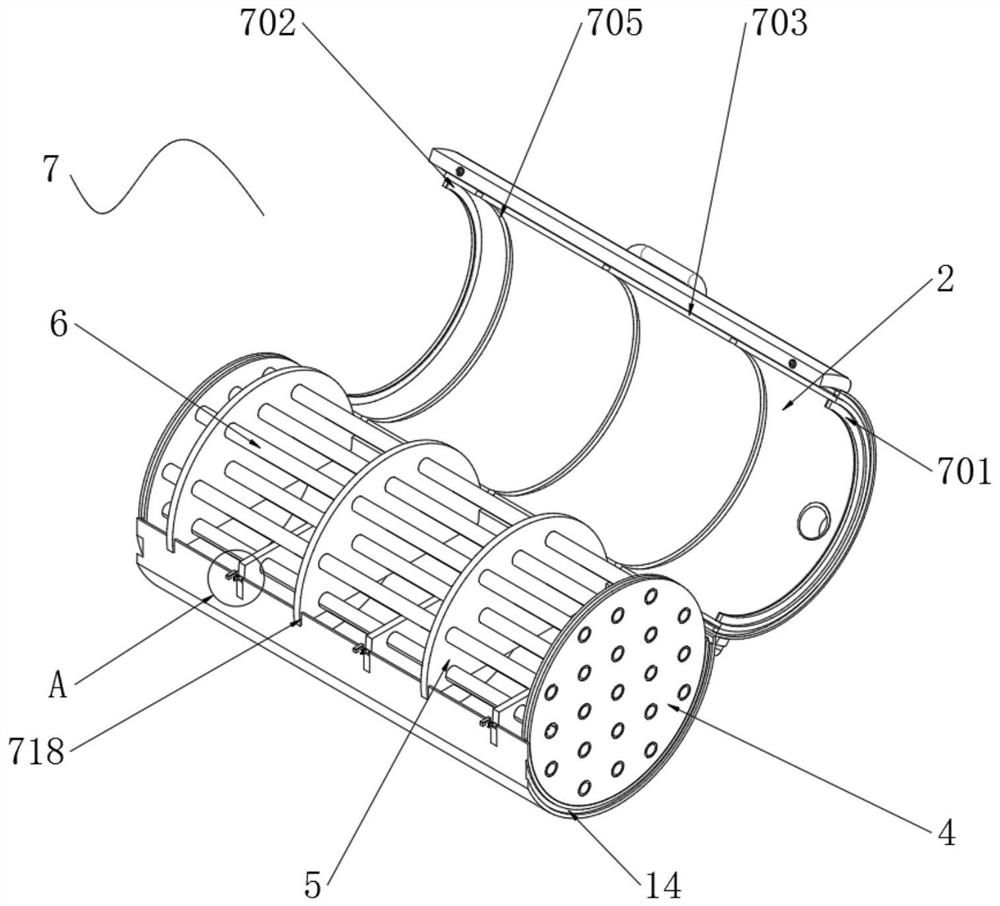

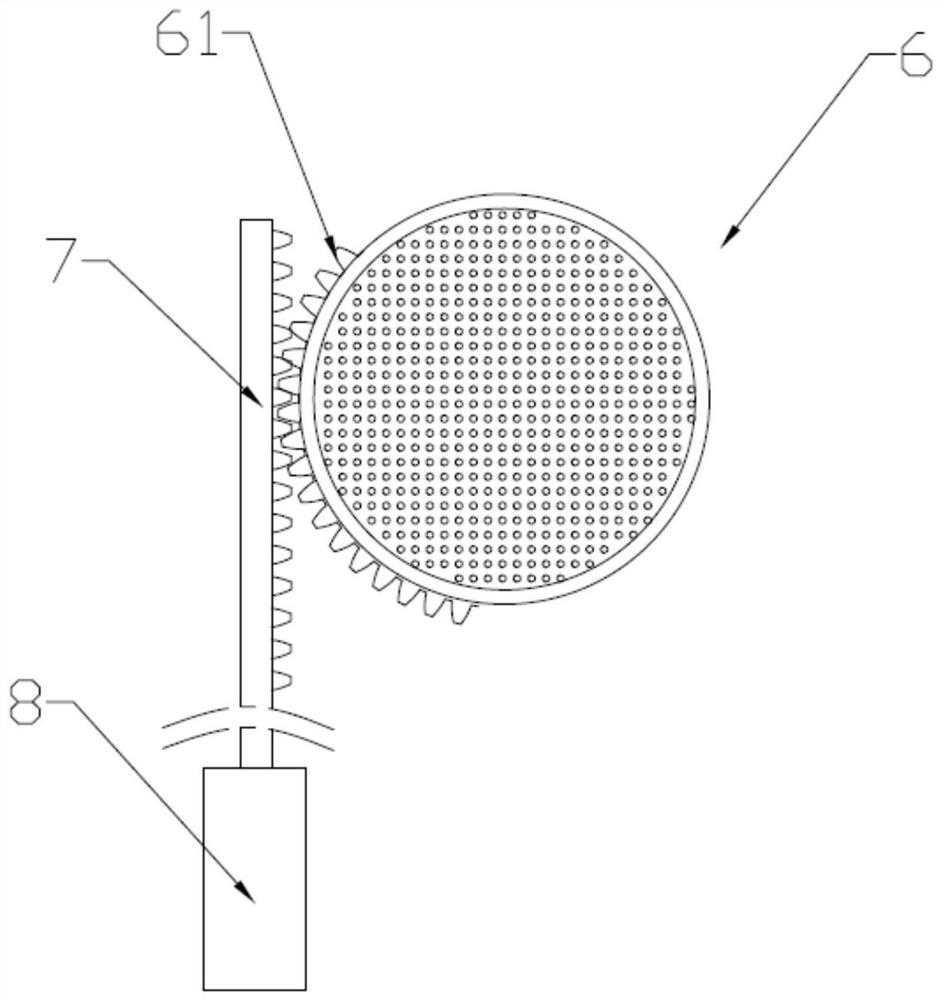

a screw conveyor

ActiveCN109647025BCleanup impactAvoid accumulationStationary filtering element filtersSewage treatmentScrew conveyor

Owner:佛山市高明区浩辉水处理有限公司

A Flood Online Monitoring and Alarming System Applied in Cities

ActiveCN112562269BImprove work efficiencyCleanup impactHuman health protectionFouling preventionAlarm deviceScreen filter

The invention discloses an on-line flood monitoring and alarm system applied to cities, which includes a box body and an alarm device. A switch button is fixedly connected to the top of the inner side wall of the box body, and a slide bar is fixedly connected to the inner side wall of the box body. The outer wall of the slide bar is slidably connected with a floating ball, the outer wall of the floating ball is fixedly connected with a floating plate, and the outer wall of the floating plate is fixedly connected with a cleaning plate. Timely monitoring and alarming, and through the buoyancy of water, the cleaning of the inner wall of the device is realized to prevent excessive dirt on the inner wall of the device from affecting the timely monitoring and monitoring of floods, and the cleaning of the outer wall of the filter is realized through the flow of water, preventing It eliminates the blockage of the filter caused by the dirt in the long-term working water of the filter, and the threat to the people caused by the untimely monitoring and alarm, which greatly saves resources and improves the working efficiency and timeliness of the device.

Owner:CHANGAN UNIV

Surface cleaning device for metal recovery

InactiveCN111921926AEasy to cleanAvoid interferenceCleaning using toolsSurface cleaningStructural engineering

The invention discloses a surface cleaning device for metal recovery. The device comprises two fixing plates, the outer walls of the opposite sides of the two fixing plates are fixedly connected withiron chains, the outer walls of one sides of the iron chains are fixedly connected with cleaning plates, the outer wall of the top of each cleaning plate is provided with a cleaning opening, the innerwall of the bottom of each cleaning opening is connected with a cleaning brush through a hinge, and the cleaning brushes are distributed in a funnel shape. A plurality of barbs are arranged on the outer wall of one side of each cleaning brush, the outer walls of the opposite sides of the two fixing plates are each fixedly connected with two fixing blocks, and the two sides of the outer walls of the tops and the two sides of the outer walls of the bottoms of the cleaning plates are fixedly connected with balls. The interference caused to cleaning of a metal rod by the fact that large impurities are bonded to the surface of the metal rod can be prevented, the influence caused on the cleaning of the metal rod by the fact that stubborn impurities are bonded to the surface of the metal rod andare not easy to remove can be prevented, and the metal rod can be effectively cleaned according to the size of the metal rod.

Owner:邱洁

Kitchen waste disposer

PendingCN110424502AReduce crushImprove crushing efficiencyDomestic plumbingTriangular prismEngineering

The invention discloses a kitchen waste disposer, belongs to the technical field of waste cleaning devices and aims to provide a kitchen waste disposer which has good waste crushing effect, good crushed waste cleaning effect and convenient cleaning and dredging of water leakage holes. The kitchen waste disposer comprises a shell, a motor, a cutter disc and a crushing ring, wherein the shell comprises a processing cavity and a cleaning cavity which mutually communicates with one another, a sewage discharge pipe communicating with the cleaning cavity is arranged on the shell, a crushing cutter head rotationally connected with the cutter disc is arranged on the cutter disc, a plurality of water leakage holes are arranged on the cutter disc, three blades which surround a shaft lever and are uniformly distributed are arranged on the cutter disc, the blades are all arranged in the cleaning cavity, the blades are bent in the axial radial direction of the cutter disc, a first positioning headand a second positioning head for limiting the crushing cutter head are arranged on the cutter disc, the crushing cutter head comprises a cutter plate rotationally connected with the cutter disc and acrushing head connected with the cutter plate, the crushing head is in a triangular prism shape, and the section of the crushing head is in a step shape.

Owner:沈春良

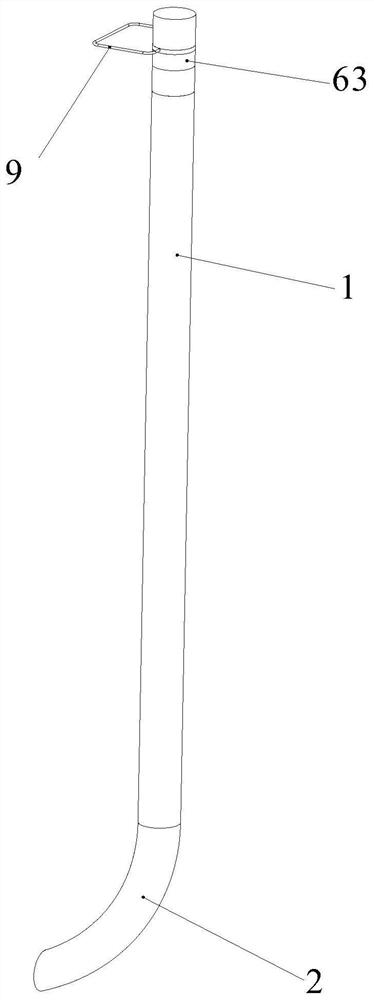

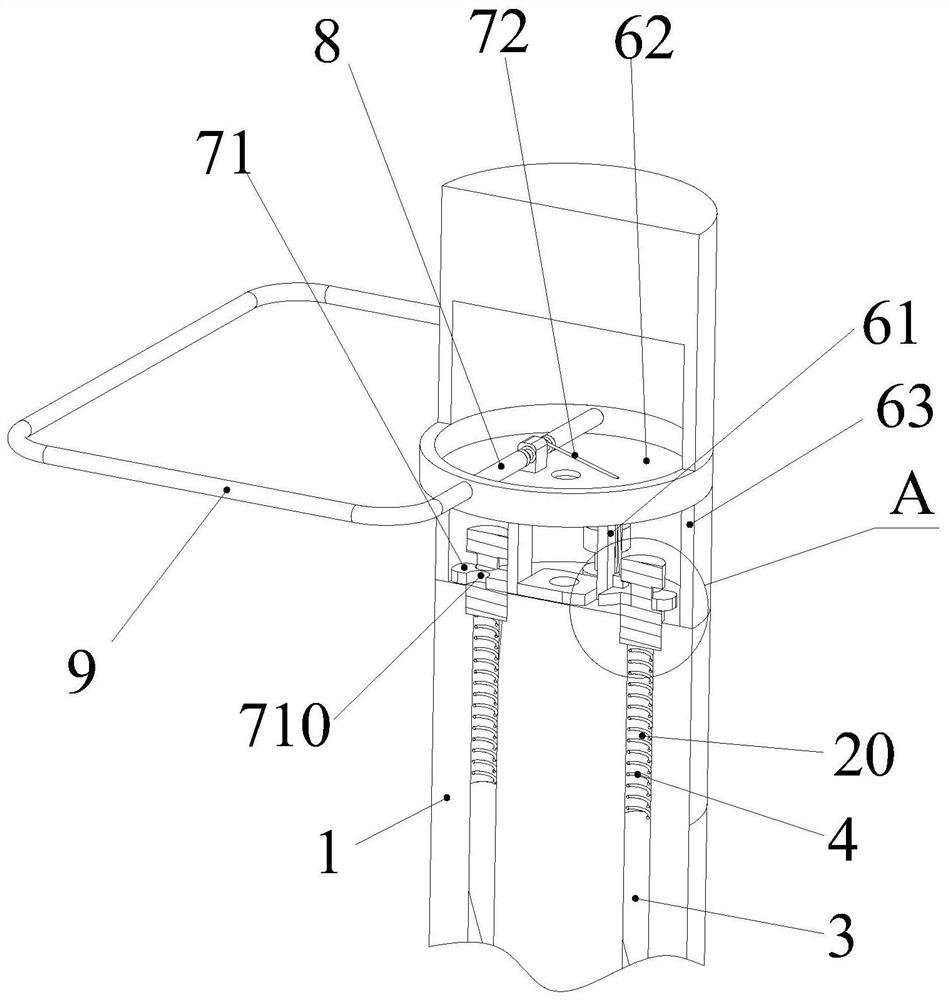

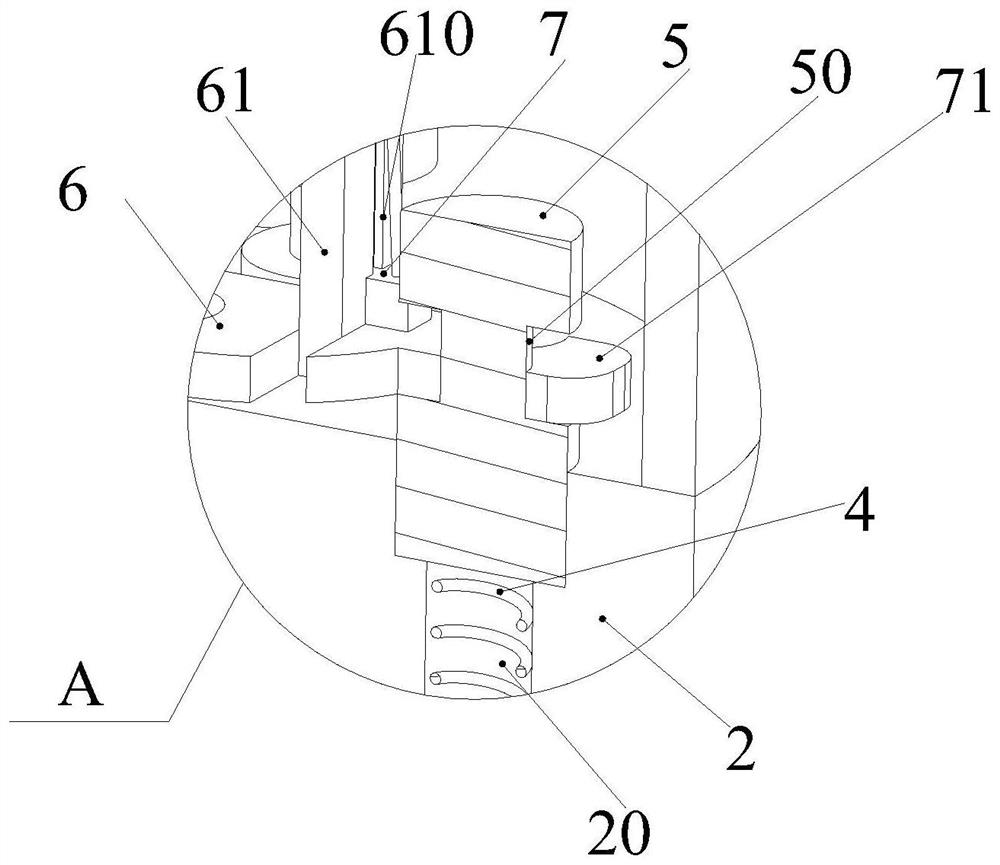

Flexible lens of electronic bronchoscope

InactiveCN113647896AAchieve four-way bendingOvercome limitationsBronchoscopesLaryngoscopesBronchoscopesApparatus instruments

The invention belongs to the field of medical instruments and discloses a flexible lens of an electronic bronchoscope, which comprises a soft lens body, the soft lens body comprises a linear part and a bent part arranged at one end of the linear part, a pull wire is arranged in the bent part, one end of the pull wire is fixed to the end, away from the linear part, of the bent part, and the other end of the pull wire extends out of the linear part until the end, which deviates from the bent part, of the straight line part; the number of the drawing wires is four, and the four drawing wires are evenly arranged on the peripheral side of the bent part and extend towards the linear part along the axis of the soft lens till extending out of the linear part. According to the flexible lens, the four drawing wires are arranged, the four drawing wires are pulled respectively, so that the bending parts are bent in the direction of the pulled drawing wires, the bending direction is actually selected according to needs, the corresponding drawing wires are selected for pulling, and therefore four-direction bending is achieved, and the operation limitation that only two-direction bending exists in the prior art is avoided.

Owner:NANJING FIRST HOSPITAL

Long-life sewage treatment equipment

The invention discloses sewage treatment equipment with long service life. The sewage treatment equipment with long service life comprises a box body, a filtering device is arranged in the box body; awater inlet is formed in the top of the box body; a water inlet pipe matched with the water inlet is arranged at the top of the box body; a water outlet is formed in the bottom of the box body, the filtering device comprises a supporting frame arranged on the inner wall of the box body, a supporting table arranged on the supporting frame and a waste material box arranged on the supporting table;a water storage cavity is formed in the bottom of the box body, the water outlet is formed in the top of the water storage cavity, and a cleaning assembly is arranged in the water storage cavity; impurities in the sewage are uniformly collected through the waste material box and the water storage cavity, so that the impurities in the box body are uniformly cleaned, the impurity cleaning difficultyis reduced, and the service life of the equipment is prolonged.

Owner:林建国

An adjustable cloth-feeding brush device for textile use and its application method

InactiveCN110790059BCleanup impactHealth hazardMechanical cleaningPressure cleaningEngineeringBrush device

The invention discloses an adjustable cloth feeding hairbrush device for spinning and a use method thereof. The adjustable cloth feeding hairbrush device for the spinning comprises a bottom seat, a drive roller and a driven roller, wherein vertical plates are symmetrically and fixedly connected with the upper end of the bottom seat, an adjusting device used for adjusting the position of the drivenroller is installed on the bottom seat, and a first drive device used for driving the driven shaft to rotate is installed on a double-shaft motor. The invention further provides a use method of the adjustable cloth feeding hairbrush device for the spinning. The use method of the adjustable cloth feeding hairbrush device for the spinning includes the following steps: S1, checking if all device parts on the cloth feeding hairbrush device are undamaged; and S2, enabling textile cloths to pass through space between the drive roller 3 and the driven roller 4. By arranging a telescopic rod rotatably connected with the side wall of a fixing block, adjusting the telescopic rod to separate a third tapered gear from a fourth tapered gear, and then adjusting an interval between the drive roller andthe driven roller through an adjusting air cylinder, the adjustable cloth feeding hairbrush device for the spinning can perform corresponding adjustment on the thickness of the different textile cloths, and prevents the phenomena that the textile cloths are jammed and cloth feeding effects for the textile cloths are not obvious from occurring.

Owner:绍兴柯桥友和纺织品有限公司

A self-sprinkling intelligent pipeline detection and cleaning robot

ActiveCN111036631BReduce distanceHigh cleaning safety factorHollow article cleaningSprayerControl engineering

Owner:南通新森亚环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com