Q420 zinc plating degreasing and iron removing device and using method thereof

A technology for cleaning boxes and plates, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, heating devices, etc., which can solve the problems of inability to clean workpieces, inability to remove grease and iron powder on the surface of workpieces, and affecting galvanization of workpieces, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

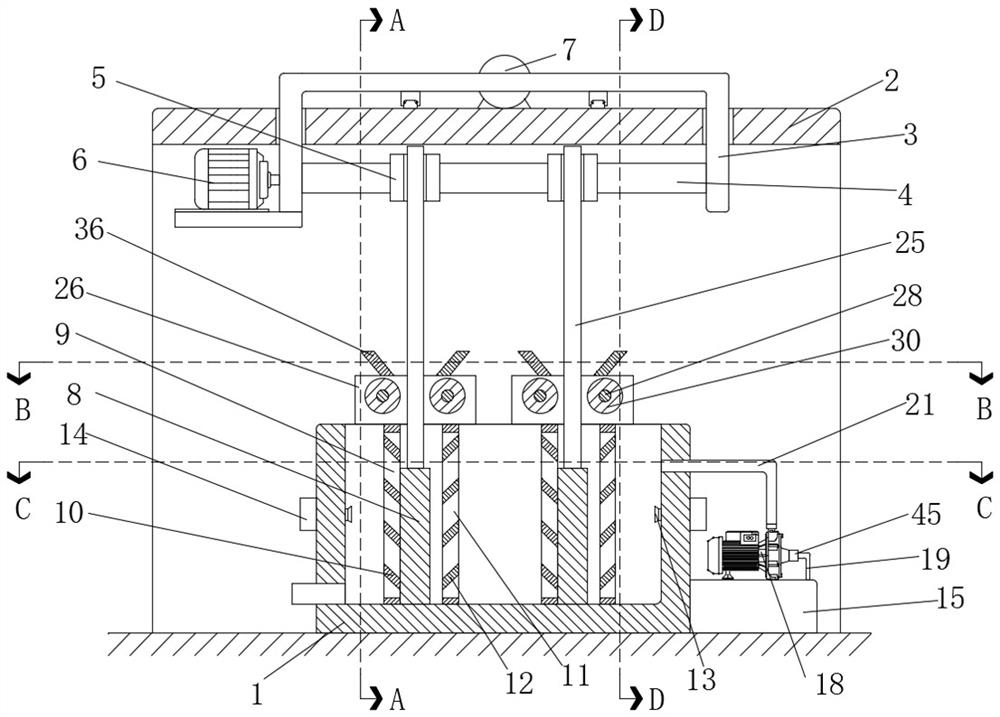

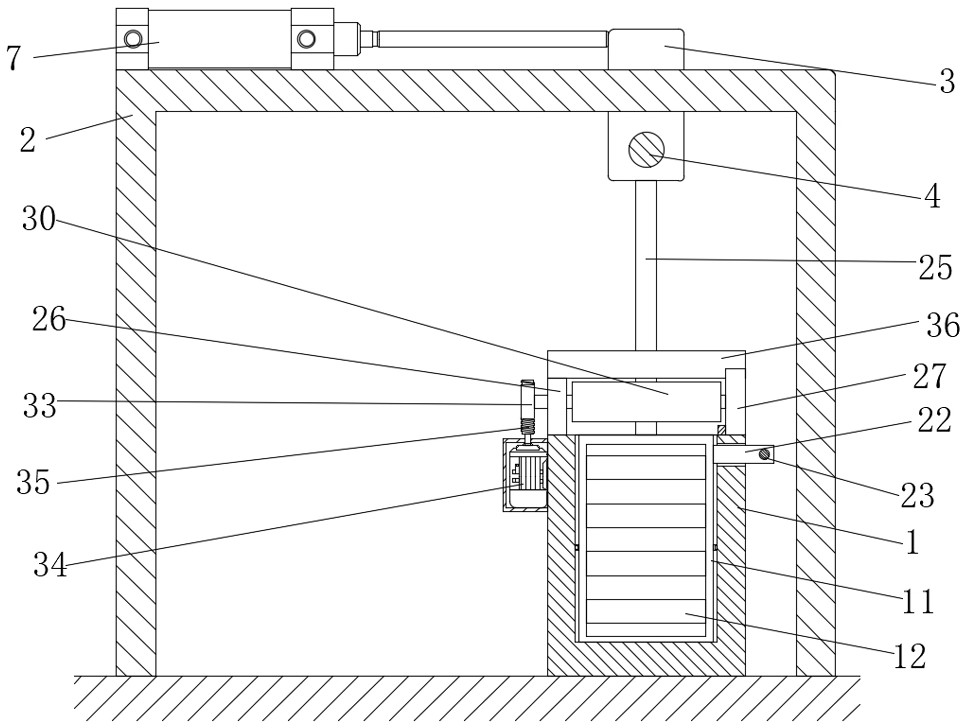

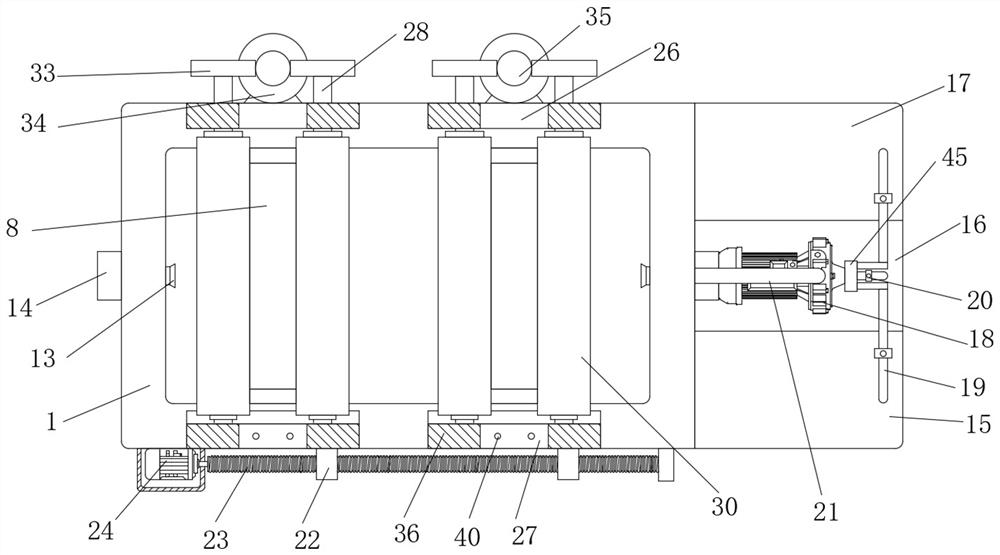

[0042] refer to Figure 1-8 , a Q420 galvanized degreasing and iron removal device, including a cleaning box 1, one side of the cleaning box 1 is provided with a drain pipe, the cleaning box 1 is provided with two symmetrical plates 8, and the top of the cleaning box 1 is provided with a As for the moving components of the moving plate 8, the top of the cleaning box 1 is provided with two sets of symmetrical cleaning components for preliminary cleaning of the surface of the plate 8, and the inside of the cleaning box 1 is provided with two sets of symmetrical cleaning components for cleaning the plate 8. Scraping components for scraping off oil stains and iron powder on the surface. One side of the cleaning box 1 is provided with an adding component for adding corresponding solutions to the cleaning box 1. Both sides of the cleaning box 1 are fixedly connected with ultrasonic generators 14. Cleaning An ultrasonic transducer 13 matched with an ultrasonic generator 14 is fixedly...

Embodiment 2

[0056] refer to Figure 1-9 , a Q420 galvanized degreasing and iron removal device, including a cleaning box 1, one side of the cleaning box 1 is provided with a drain pipe, the cleaning box 1 is provided with two symmetrical plates 8, and the top of the cleaning box 1 is provided with a As for the moving components of the moving plate 8, the top of the cleaning box 1 is provided with two sets of symmetrical cleaning components for preliminary cleaning of the surface of the plate 8, and the inside of the cleaning box 1 is provided with two sets of symmetrical cleaning components for cleaning the plate 8. Scraping components for scraping off oil stains and iron powder on the surface. One side of the cleaning box 1 is provided with an adding component for adding corresponding solutions to the cleaning box 1. Both sides of the cleaning box 1 are fixedly connected with ultrasonic generators 14. Cleaning An ultrasonic transducer 13 matched with an ultrasonic generator 14 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com