Dust removal device for cotton yarn spinning workshop

A dust removal device and workshop technology, which is applied in the field of cotton yarn textiles, can solve the problems of reduced dust and lint treatment efficiency, and achieve the effects of increasing the contact area, improving the treatment efficiency, and speeding up the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

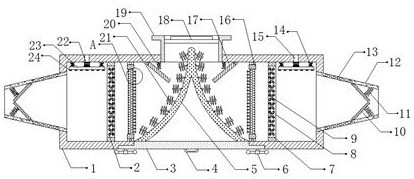

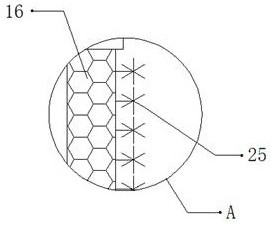

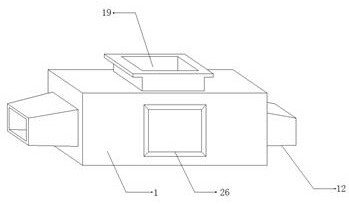

[0029] refer to Figure 1-3 , a kind of dust removal device for cotton yarn textile workshop, comprising a box body 1, the outer walls of both sides of the box body 1 are provided with exhaust ports, and the inner walls of the two exhaust ports are connected with exhaust pipes 12 by bolts, and the two exhaust ports The both sides outer wall of trachea 12 is all provided with port, and the inwall of port is connected with strainer 13 by bolt, and the top outer wall of box body 1 is provided with air inlet, and the inwall of air inlet is provided with air inlet pipe 19, The inner wall of the air inlet pipe 19 is connected with a fan 18 by bolts, the bottom outer wall of the box body 1 is provided with a counterbore, and the inner wall of the counterbore is clamped with a fixed plate 3, the two sides of the outer wall of the bottom of the fixed plate 3 and the two sides of the inner wall of the top of the counterbore. Both sides are provided with threaded openings, and the inner ...

Embodiment 2

[0040] refer to Figure 4 , a dust removal device for a cotton yarn spinning workshop. Compared with Embodiment 1, the two sides of the outer wall of the bottom of the box body 1 are connected with vibration motors 27 by bolts, which can process the dust adhering to the inner wall of the device.

[0041] Working principle: When in use, start the fan 18, and the fan 18 will absorb the dust and lint into the interior of the box body 1. When the dust and lint enter the interior of the device through the fan 18, the dust and lint can be removed by the guide plate 5. Perform shunt treatment to speed up the processing efficiency of the device for dust and lint, and prevent dust and lint from gathering together to affect the processing efficiency of the device. The first barb 21 in the shape of "Feng" can increase the amount of lint The contact area with the first barb 21 is so that the lint can be effectively fixed on the first barb 21, so that the lint can be processed, and the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com