Kitchen waste disposer

A kitchen waste and processor technology, which is applied to indoor sanitary pipe installations, water supply installations, buildings, etc., can solve problems such as blockage, poor garbage cleaning effect, and inconvenience for the processor to block and clean up leaking holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

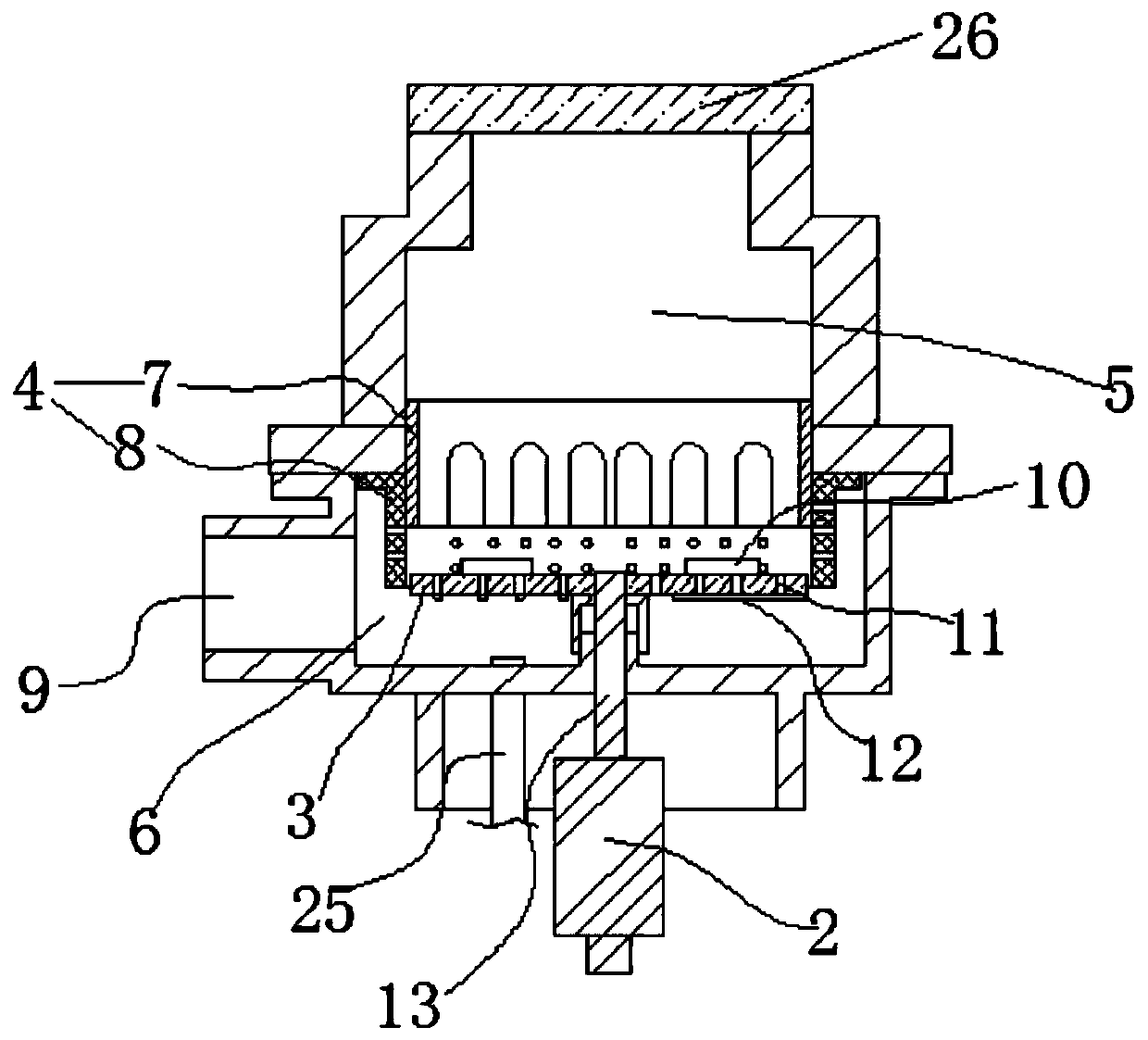

[0019] refer to Figure 1 to Figure 7 The embodiments of the present invention will be further described.

[0020] Disclosed is a kitchen waste disposer which has good garbage crushing effect, good cleaning effect of crushed garbage, and convenient cleaning and dredging of water leakage holes.

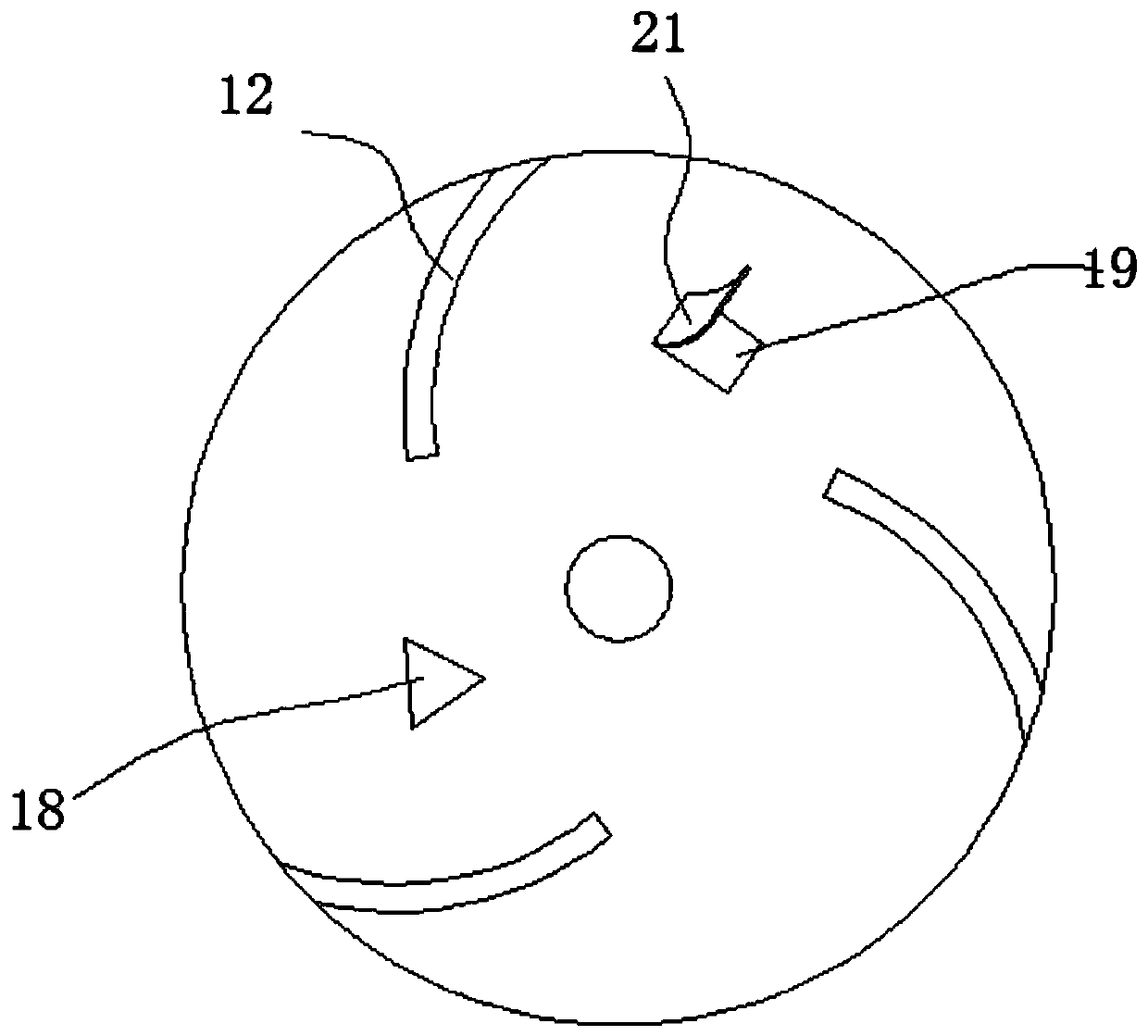

[0021] A specific embodiment of the present invention: a kitchen waste disposer, including a casing 1, a motor 2, a cutter head 3 and a crushing ring 4, the casing 1 includes a processing chamber 5 and a cleaning chamber 6 connected to each other, and the crushing ring 4 includes interconnected The first ring body 7 and the second ring body 8, the first ring body 7 is inserted into the processing chamber 5, the second ring body 8 is placed in the cleaning chamber 6, the cutter head 3 extends into the second ring body 8, and the motor 2 The shaft 13 is connected with the cutterhead 3 and drives the cutterhead 3 to rotate. The shell 1 is provided with a sewage pipe 9 communicating with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com