Surface cleaning device for metal recovery

A surface cleaning and metal technology, which is applied in the direction of using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of large impurities and difficult to clean, and the influence of metal rod cleaning, etc. The effect of high squeezing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

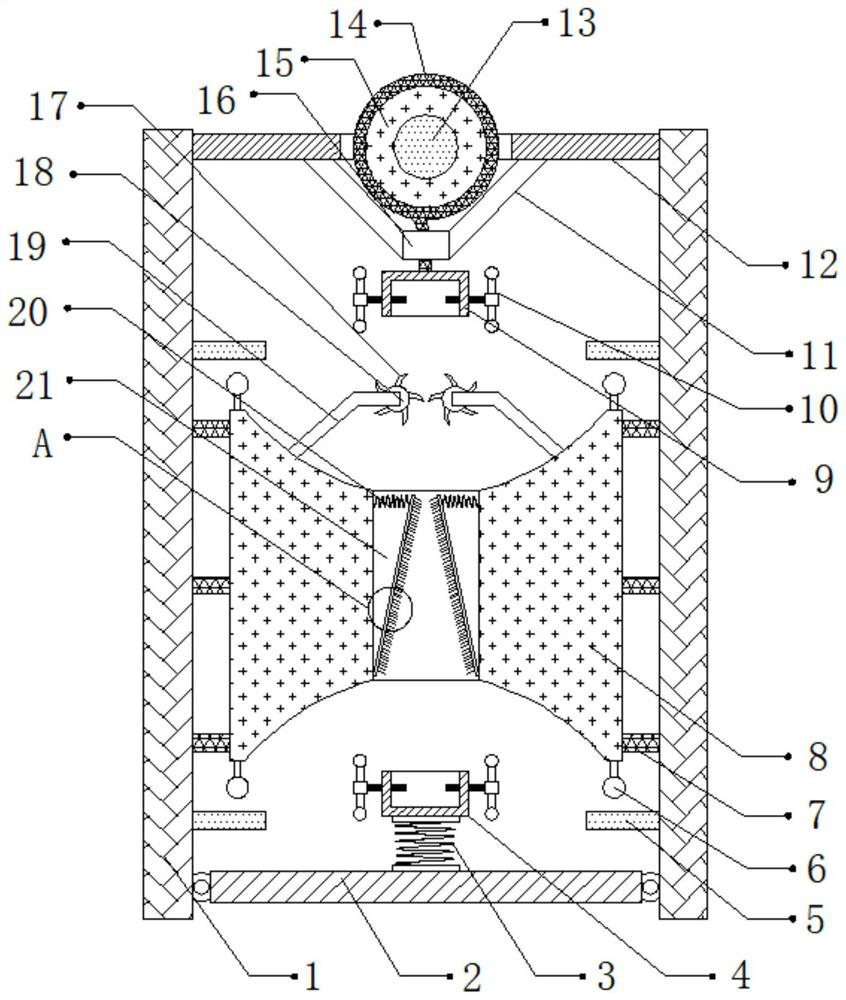

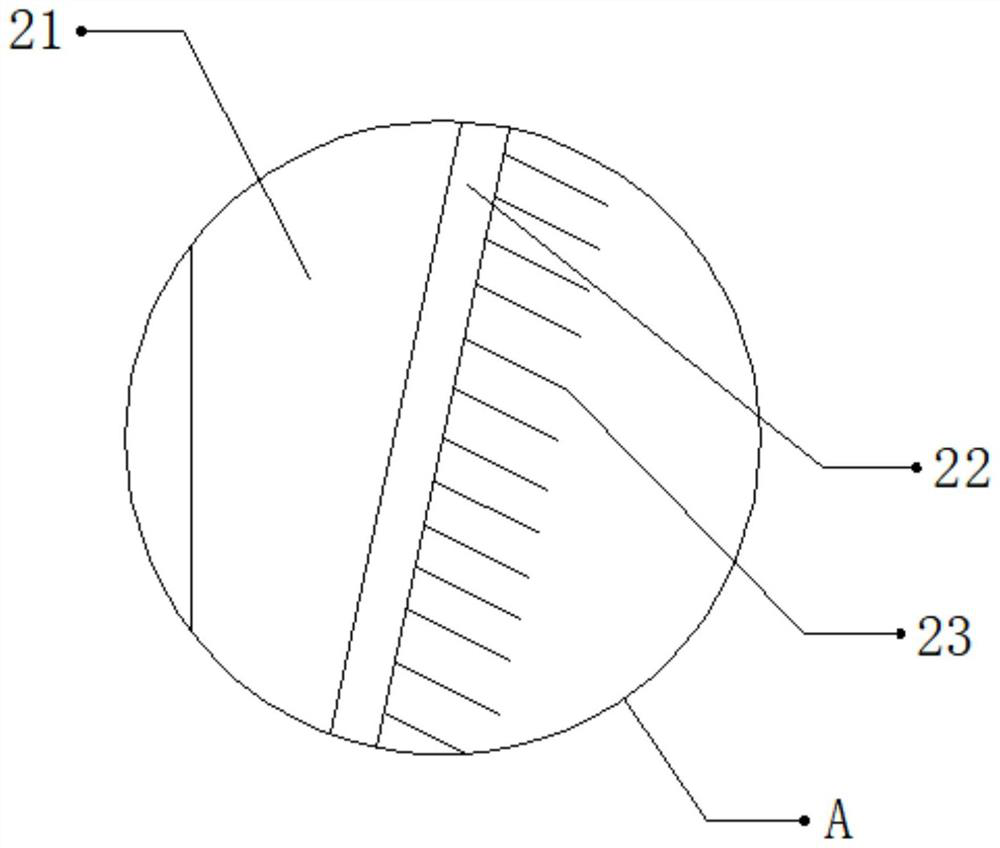

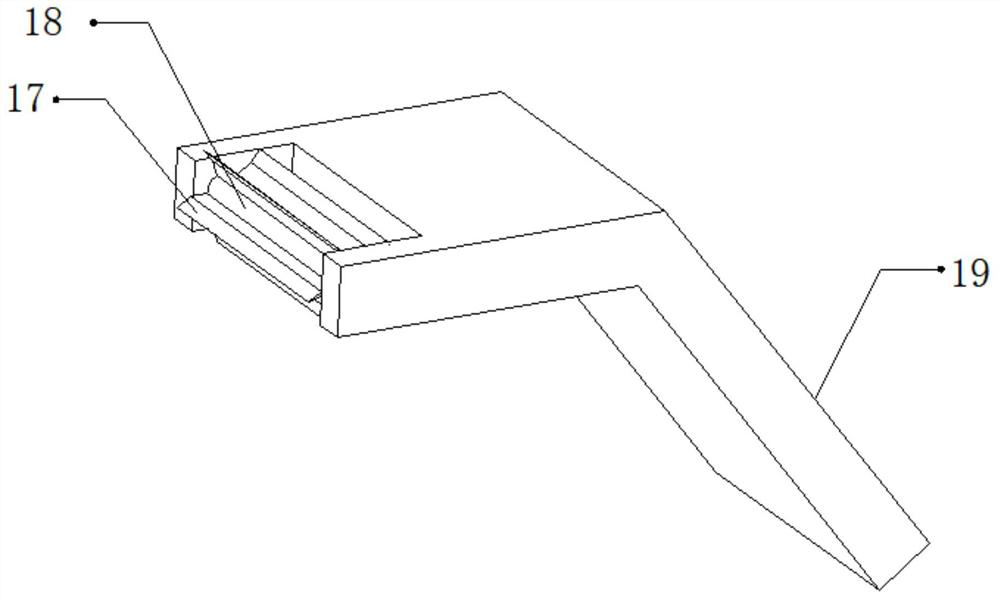

[0027] refer to Figure 1-3 , a surface cleaning device for metal recovery, comprising two fixed plates 1, the outer walls of the opposite sides of the two fixed plates 1 are connected with iron cables 7 by bolts, and the outer walls of one side of the iron cables 7 are connected with cleaning plates 8 by bolts, The top outer wall of cleaning plate 8 is provided with cleaning port 21, and the bottom inner wall of cleaning port 21 is connected with cleaning brush 22 by hinge, and cleaning brush 22 is funnel-shaped distribution, and one side outer wall of cleaning brush 22 is provided with a plurality of barbs 23, The opposite side outer walls of the two fixed plates 1 are all connected with two fixed blocks 5 by bolts, and the both sides of the top outer wall of the cleaning plate 8 and the both sides of the bottom outer wall are all connected with spheres 6 by bolts, and the spheroids 6 and the fixed blocks 5 Correspondingly, the position of the outer walls on the opposite sid...

Embodiment 2

[0036] refer to Figure 4 , a surface cleaning device for metal recovery. Compared with Embodiment 1, the outer walls of one side of the two fixed plates 1 are connected with a vibration motor 24 by bolts. When the metal rod is cleaned, the vibration motor 24 is started. , so as to deal with the impurities adhered inside the device by vibration, so as to clean the device.

[0037]Working principle: when in use, place the metal rod to be cleaned on the device, fix the bottom of the metal rod to the inside of the first fixed sleeve 4, and fix the top of the metal rod to the inside of the second fixed sleeve 9 through the cleaning port 21 Inside, twist the fastening bolt 10 to fix the two ends of the metal pipe through the fastening bolt 10. After the fixing is completed, start the motor, and the motor will drive the winding roller 15 to rotate, so as to wind the pull cord 14 , so as to drive the metal rod to reciprocate up and down, thereby cleaning the surface of the metal rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com