Cement homogenizing equipment with pre-crushing function

A homogenization equipment and pre-crushing technology, which is applied in mixers with rotary stirring devices, mixed material pretreatment, chemical instruments and methods, etc., can solve the problems of screening structure, single stirring function, large space occupation, and equipment energy consumption Advanced problems, to achieve the effect of ingenious and reasonable power connection, ingenious structural design, and prevention of accumulation and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

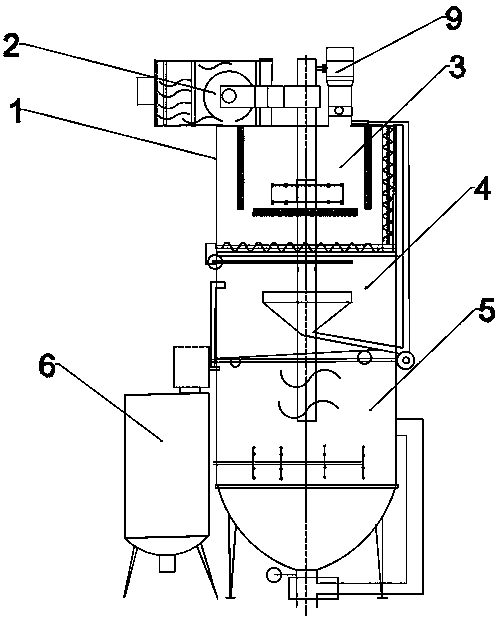

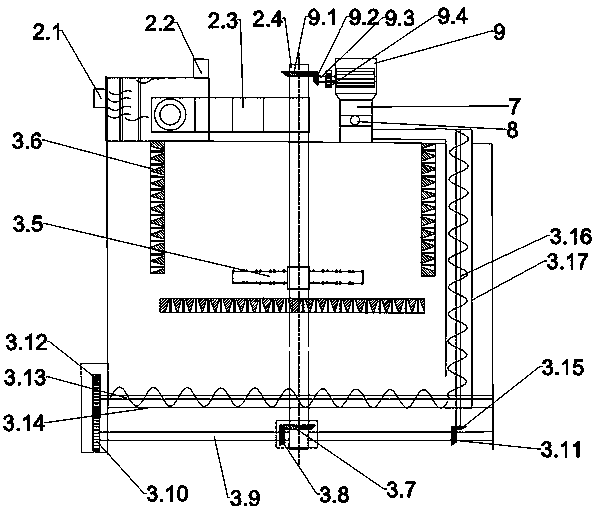

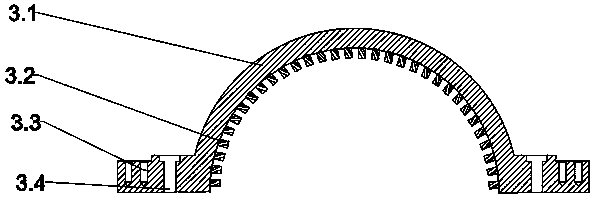

[0032] As shown in the accompanying drawings of the description, a cement homogenization equipment with pre-crushing function includes equipment tank 1, driving mechanism 2, breaking bin 3, screening bin 4, mixing bin 5, auxiliary mechanism 6 and pre-crushing equipment. Crushing mechanism 9; the driving mechanism 2 is fixed on the top of the equipment tank 1 and driven by a water turbine. Both ends of the driving mechanism 2 are connected with a water inlet 2.1 and a water outlet 2.2, and the output of the driving mechanism 2 is connected to the gearbox 2.3, the output of the gearbox 2.3 is connected to the main shaft 2.4; the main shaft 2.4 is fixed in the middle of the equipment tank 1, the upper part of the main shaft 2.4 passes through the gearbox 2.3, and the lower part passes through the breaking bin 3 and the screening bin 4 and mixing discharge bin 5; said breaking up bin 3 is provided with a breaking up cutter head 3.5, a counterattack plate 3.6, a horizontal screw con...

Embodiment 2

[0040] The structure and principle of the present embodiment 2 are basically the same as that of the embodiment 1, except that the sieve hole 3.61 is provided with a spiked partition 3.63 between the two holes, the bottom of the spiked partition 3.63 is supported, and the spikes on the head are connected to the bottom of the spiked partition. The upper sieve surface is parallel, and the material is thrown out by the centrifugal force of the breaking cutter, and then collides with the sharp part of the head of the sharp partition 3.63, so that the material can be effectively broken.

Embodiment 3

[0042] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, except that three groups of material level detection sensors 5.4 are arranged on the tank wall of the mixing discharge bin 5, and the material level detection sensors 5.4 are installed in the mixing discharge bin 5. On the upper, middle, and bottom tank walls, the feedback signal of the material level detection sensor 5.4 is connected to the control system, and the control system automatically controls the opening and closing of the switch valve 8 on the feed inlet 7 according to the change of the feedback signal, and controls the feed amount .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com