Green hedge trimmer with fertilizing and irrigating functions

A hedge trimmer and functional technology, applied in the field of hedge trimmers, can solve the problems of high use and maintenance costs, high labor intensity, affecting operation quality and operation efficiency, etc., to achieve life expectancy and personnel safety assurance, and low use and maintenance costs. , the novel effect of trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

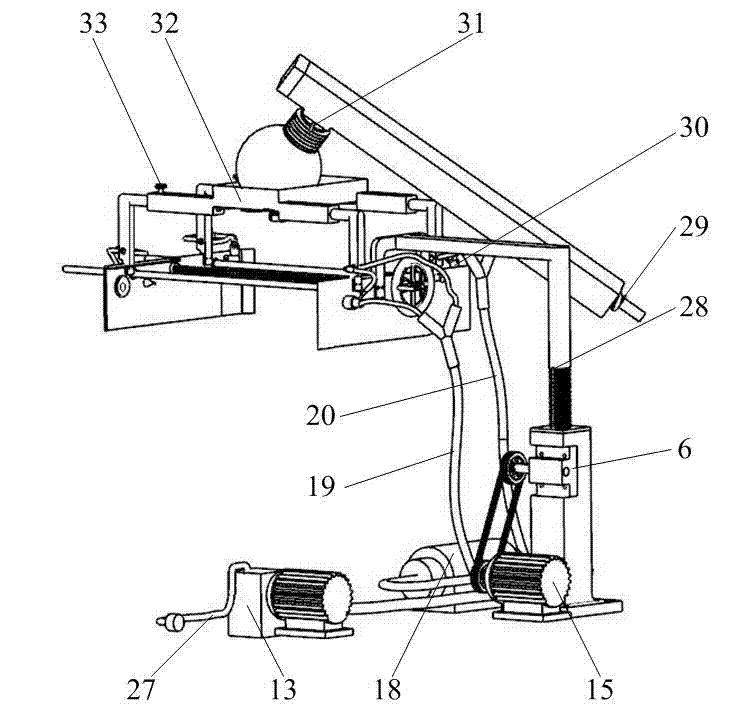

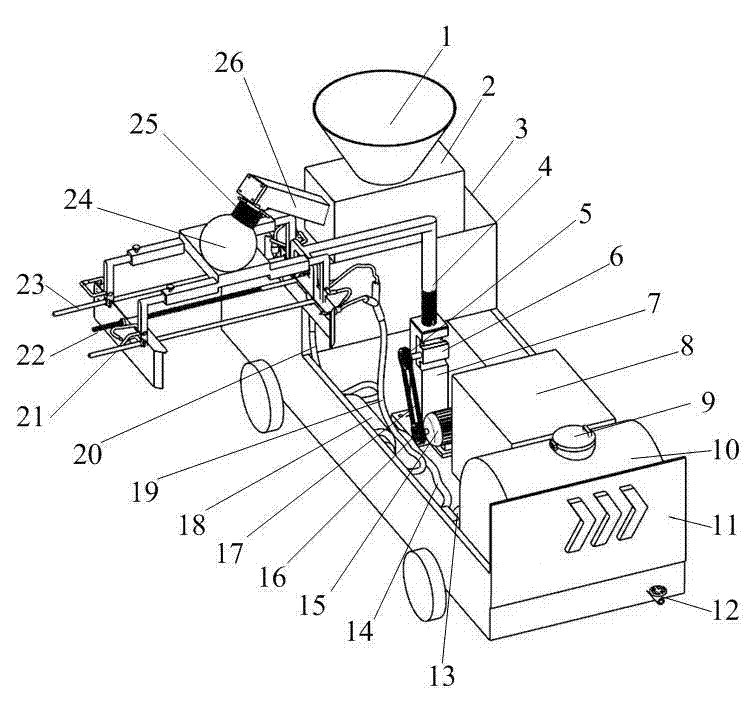

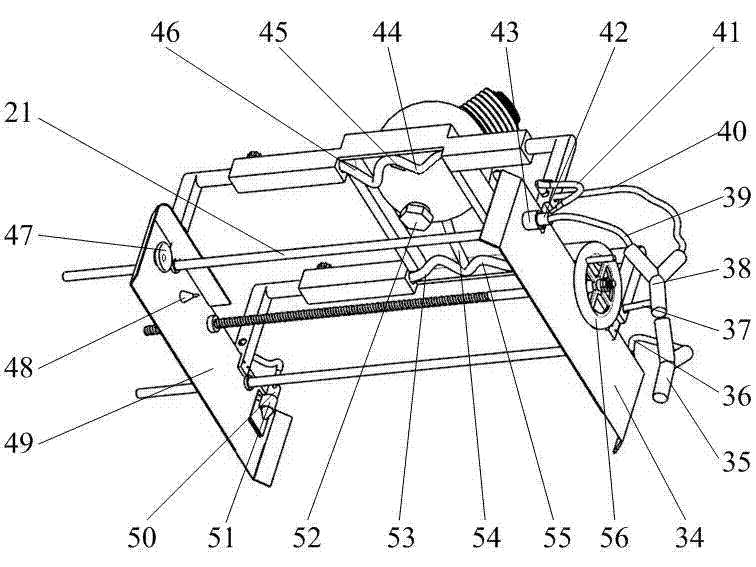

[0034] exist Figure 1 to Figure 5 In the shown embodiment: the generator 8 is fixed on the carrier vehicle 3, the warning sign 11 is fixed on the tail of the carrier vehicle 3; the fixed base 7 is fixedly connected to the carrier vehicle 3, and the lower end is provided with threads and a limit groove 28 for rotatable lifting The support 4 is threadedly connected with the fixed base 7, and the upper end of the rotatable lifting support 4 is bent into a crossbeam and fixedly connected with the water shield I 34. 16 and transmission belt 17 are formed by the belt transmission mechanism and are connected with the input end of the turbine lead screw lifter 6 after shifting speed. On the carrier vehicle 3, the water tank 10 and the water pump 13 are connected through the water pipe IV 27, the water pump 13 and the supercharger 18 are connected through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com