Micro abrasive water jet fine-finish device

A technology of material water and micro-grinding, which is used in the transformation of finishing equipment and the field of micro-abrasive water jet processing equipment, can solve problems such as low efficiency, and achieve the effects of good reliability, excellent performance and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

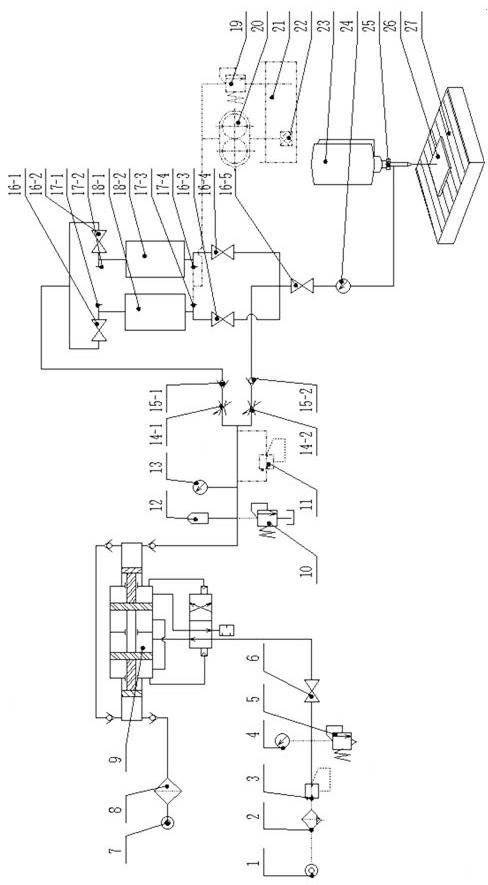

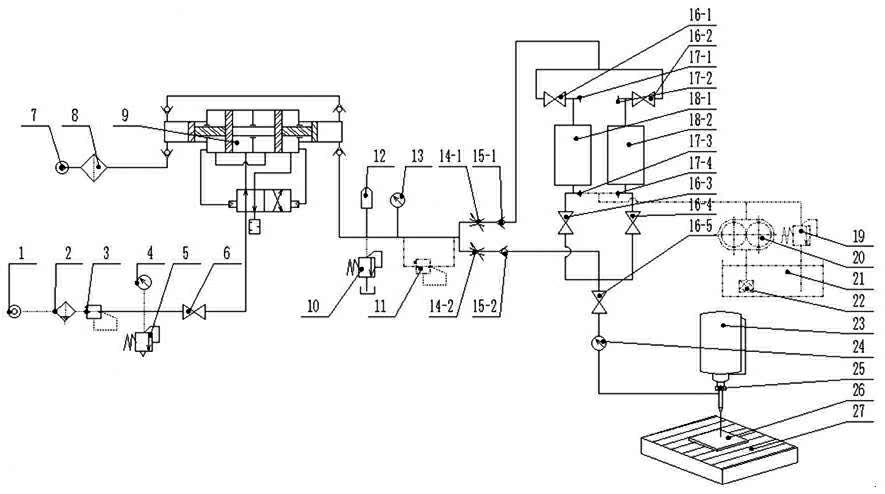

[0018] The principle diagram of the present invention is as figure 1 As shown, the microabrasive water jet finishing device of the present invention includes a booster assembly 9, a feeding assembly 18, 19, 20, etc., a cutting head assembly 25, and the feeding assembly 18, 19, 20, etc. are installed on a frame 24 and connected to the booster assembly 9 through a high-pressure hose, the cutting head assembly 25 is installed on the machining center 23, and the cutting head assembly 25 is connected to the feeding assembly 18, 19, 20, etc. through a high-pressure hose, the cutting head assembly 25 Corresponding to the position of the workpiece 26 , the workpiece 26 is installed on the worktable 27 of the machining center 23 .

[0019] In addition, the machining center 23 is provided with a vertical feed structure, and the workbench 27 is provided with a horizontal displacement structure. Through the vertical feed of the machining center and the horizontal displacement of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com