Five-axis numerical control abrasive water jet automatic polishing machine

An abrasive water jet, automatic polishing technology, applied in abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problem of no abrasive water jet polishing machine, restrict the application and development of abrasive water jet polishing technology, etc. And the effect of low cost, small reaction force, no tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

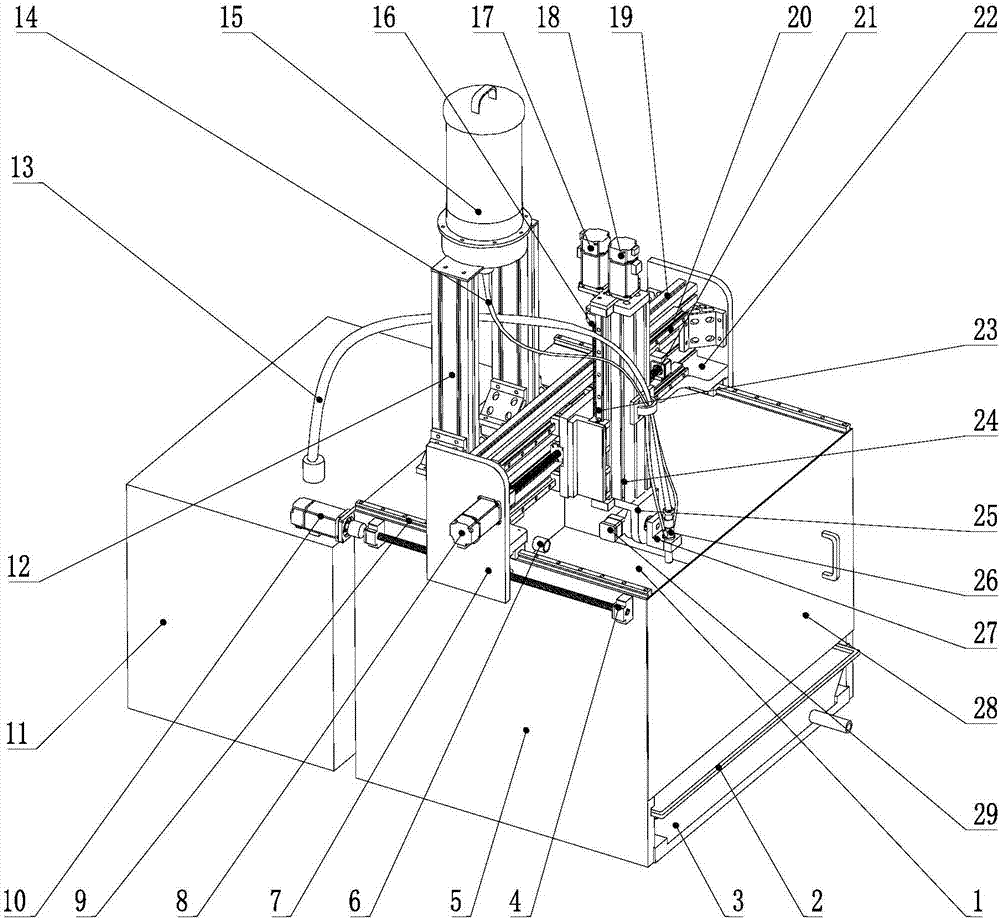

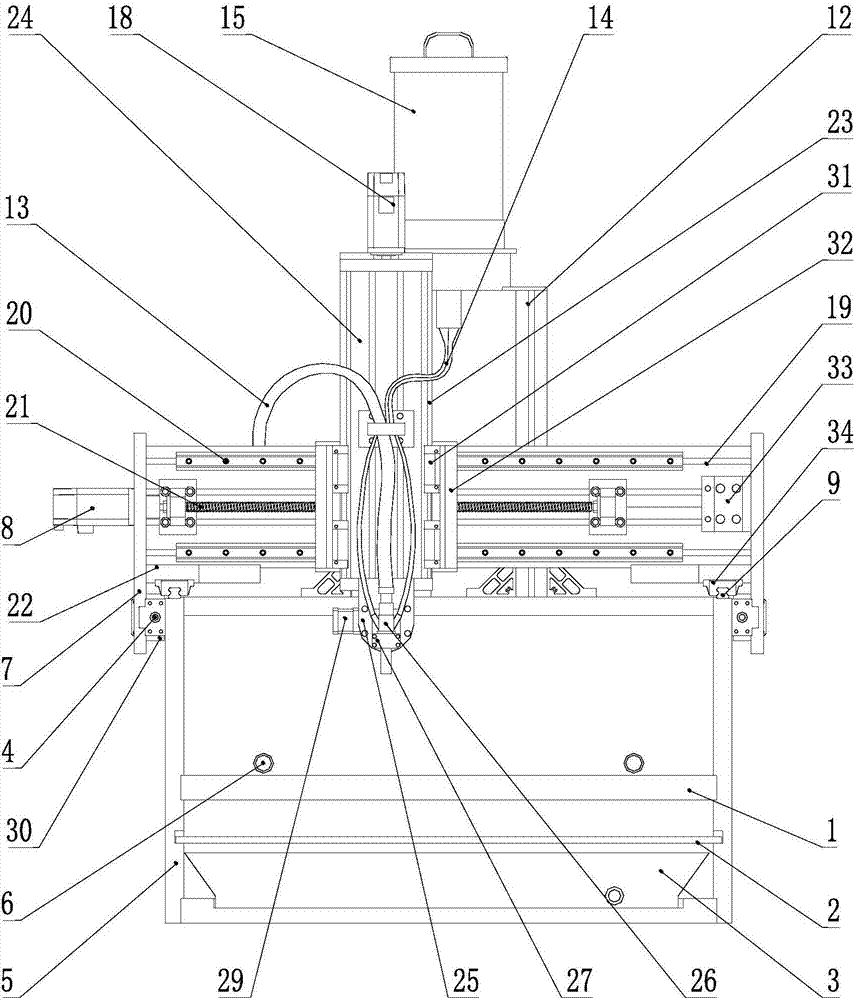

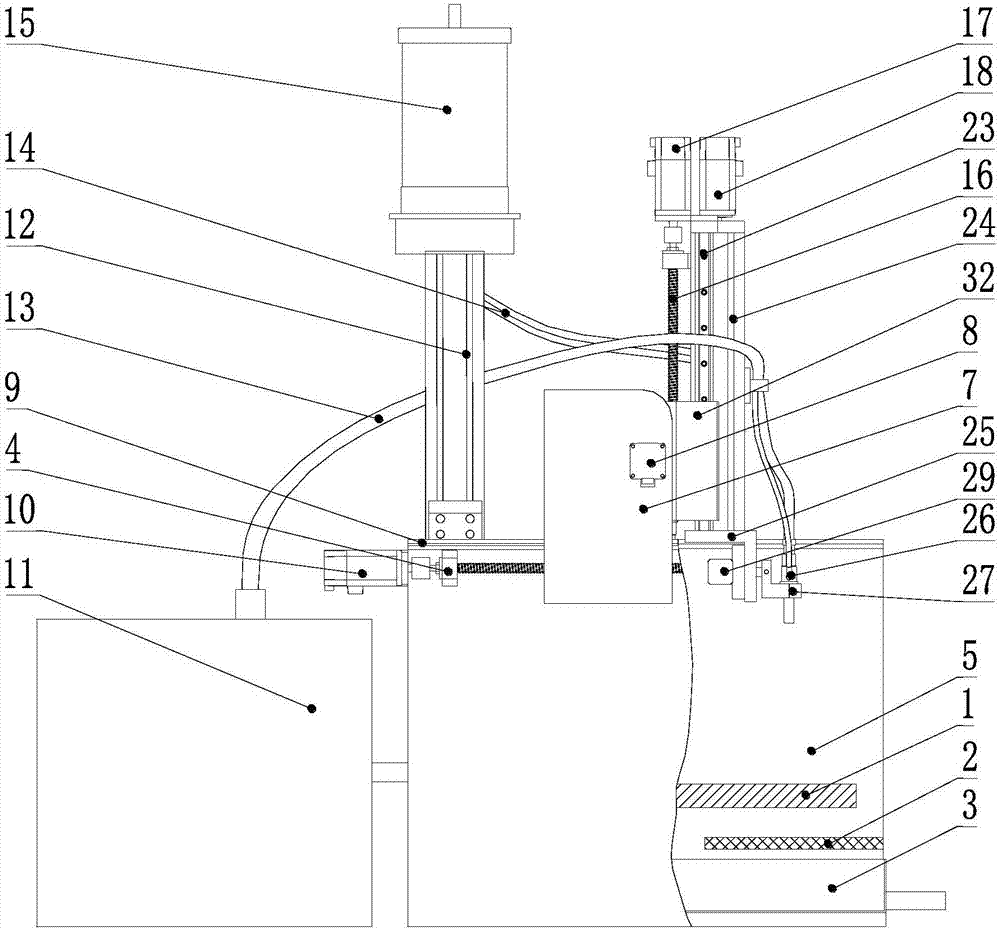

[0035] A five-axis numerical control abrasive water jet automatic polishing machine of the present invention, such as figure 1 , figure 2 , image 3As shown, it mainly includes a motion platform, an abrasive water jet nozzle, a high-pressure water generation system, and an abrasive supply system. Motion platform components: including the base 5, which is equipped with a workbench 1 inside, a filter screen 2 and a water collection tank 3 are arranged under the workbench; side panels are installed on both sides of the workbench 1, and isolation doors 28 are installed at the front ends of the two side panels The rear ends of the two side plates are fixed with baffles, and the cleaning water pipe 6 is installed on the baffle. Each has a linear guide rail 9; a crossbeam 19 is installed on the top of the base 5, and the bottom of the crossbeam 19 is installed on two cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com