Abrasive water jet nozzle and abrasive water jet machine

a technology of abrasive water jet and abrasive water jet, which is applied in the direction of abrasive equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of uneven precision or cutting process, abrasive nozzle wear, and abrasive nozzle wear further, so as to improve the precision of the cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

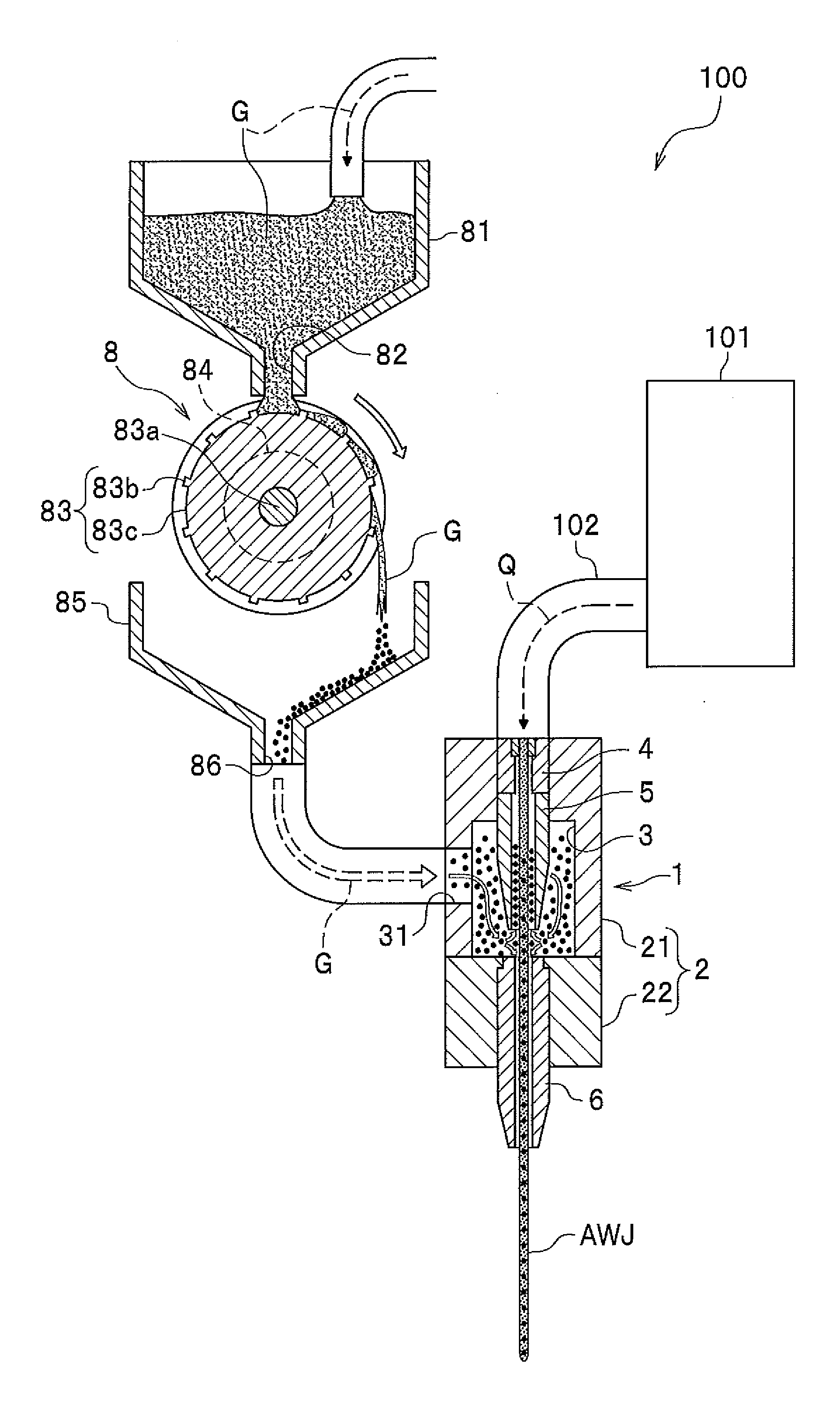

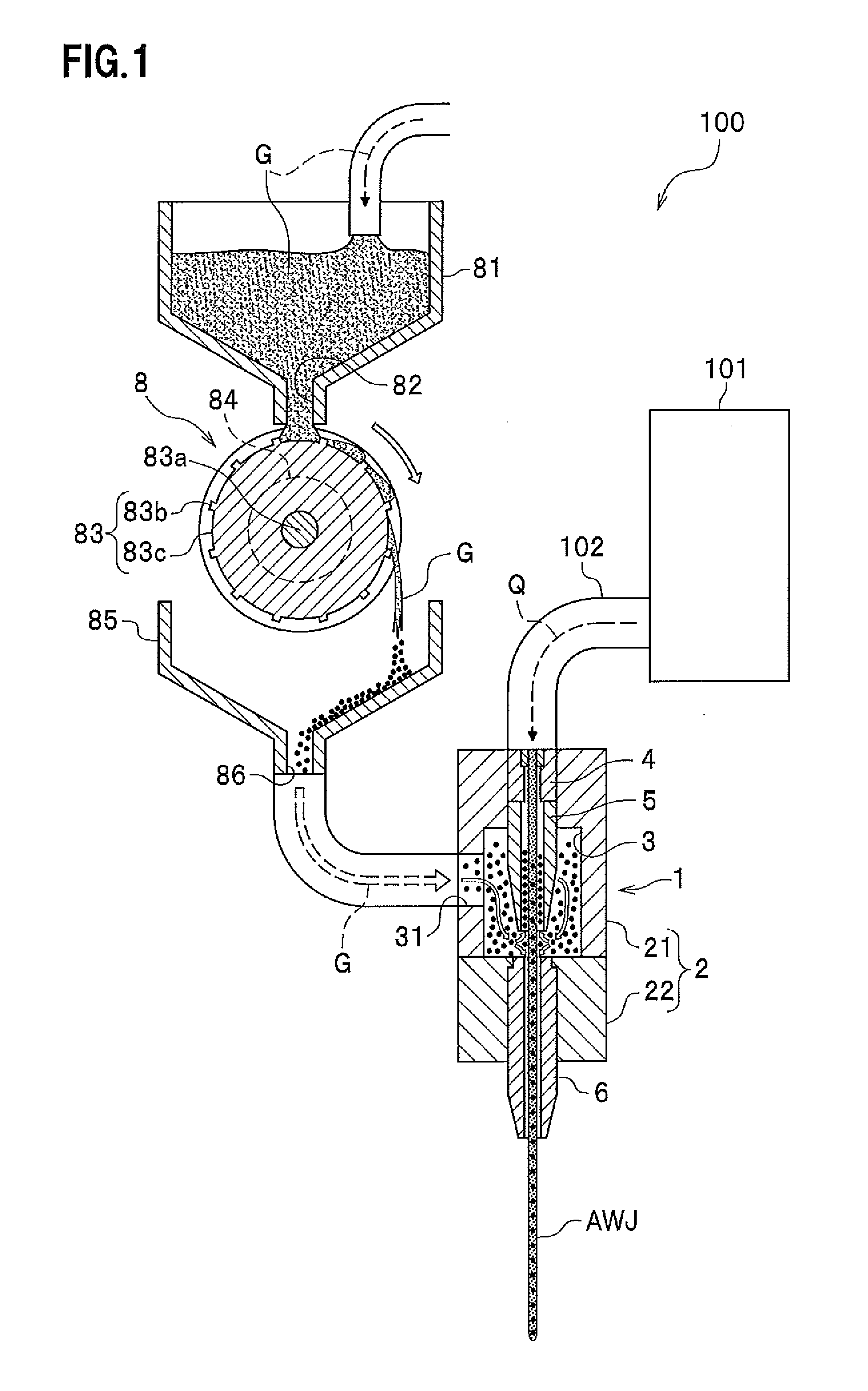

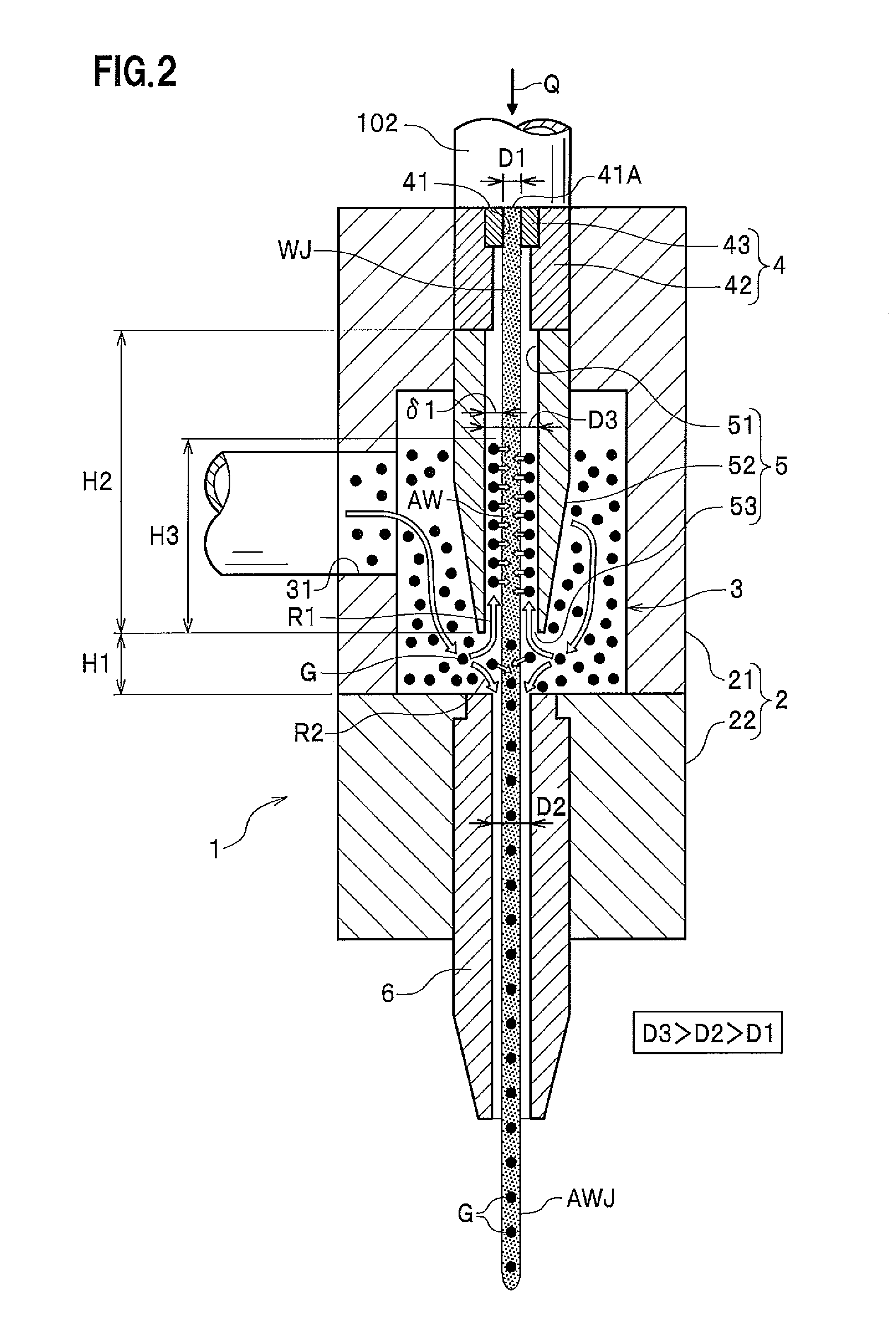

[0056]An embodiment of an abrasive water jet machine 100 according to the present invention will be described in detail with reference to the attached drawings.

[0057]The abrasive water jet machine 100 is a machine for mixing abrasives G in a water jet Q supplied at high pressure of 200 to 400 MPa, and for jetting an abrasive water jet AWJ to cut a workpiece (not shown). And the abrasive water jet machine 100 can jet the abrasive water jet AWJ at high speed over the speed of sound. Therefore, the cutting process can be done with high precision even if the workpiece is made of one of a hard material like glass, a relatively soft material like a synthetic resin, and a composite material consisting of a plurality of materials. For example, the composite material consists of the hard material, the soft material.

[0058]The abrasive water jet machine 100 comprises an abrasive water jet nozzle 1 for jetting the abrasive water jet AWJ mixed with the abrasives G, a water jet supply apparatus 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| diameter D1 | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com