Device for cutting and cleaning pre-mixed high pressure suspension grinding material water jet

A technology of abrasive water jet and cleaning device, applied in abrasive feeding device, abrasive jet machine tool, abrasive and other directions, can solve the problem of inability to flexibly control the output of high-pressure abrasive jet, inability to perform high-precision cutting and cleaning, and abrasive blockage of pipes It can improve the cutting and cleaning effect, simplify the structure and reduce wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

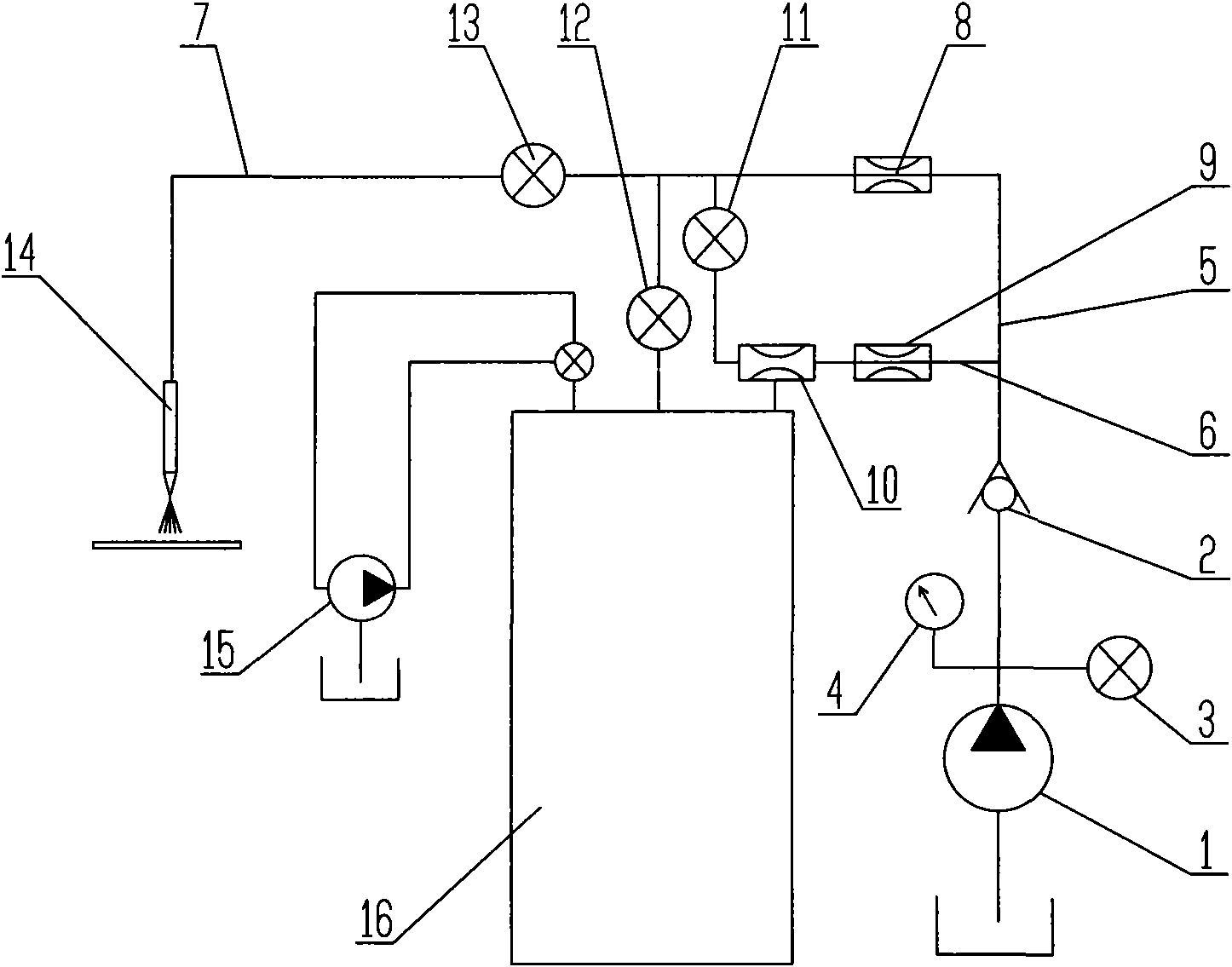

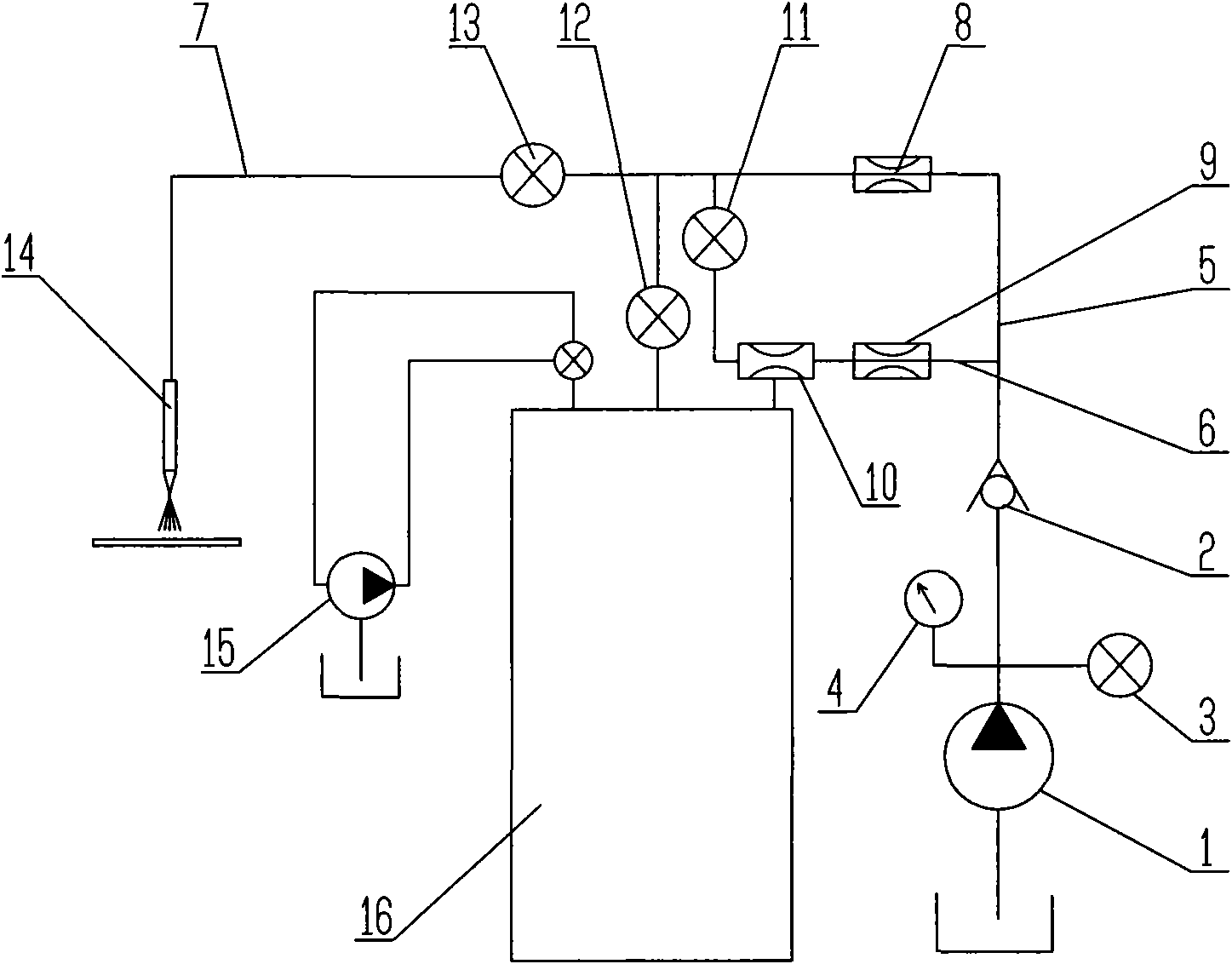

[0017] As shown in Figure 1, the high-pressure pre-mixed suspended abrasive water jet cutting and cleaning device described in the embodiment of the present invention includes an abrasive refilling device 15, an abrasive supply device 16, a high-pressure pump system, an abrasive isolation valve 12, and an abrasive supply valve. 11. Filling isolation valve 13 and nozzle 14, characterized in that: the outlet of the high-pressure pump system is divided into two lines, the main line passes through the throttle valve 8 to the filling isolation valve 13 and then to the nozzle 14, and the branch lines pass through the throttle valve 9 in turn , jet device 10, abrasive material supply device 16, abrasive material isolation valve 12 and merge with the main pipeline behind, described jet device 10 is also connected with main pipeline through pipeline with abrasive material supply device 16; Described abrasive material supply device 16 and main pipeline The abrasive isolation valve 12 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com