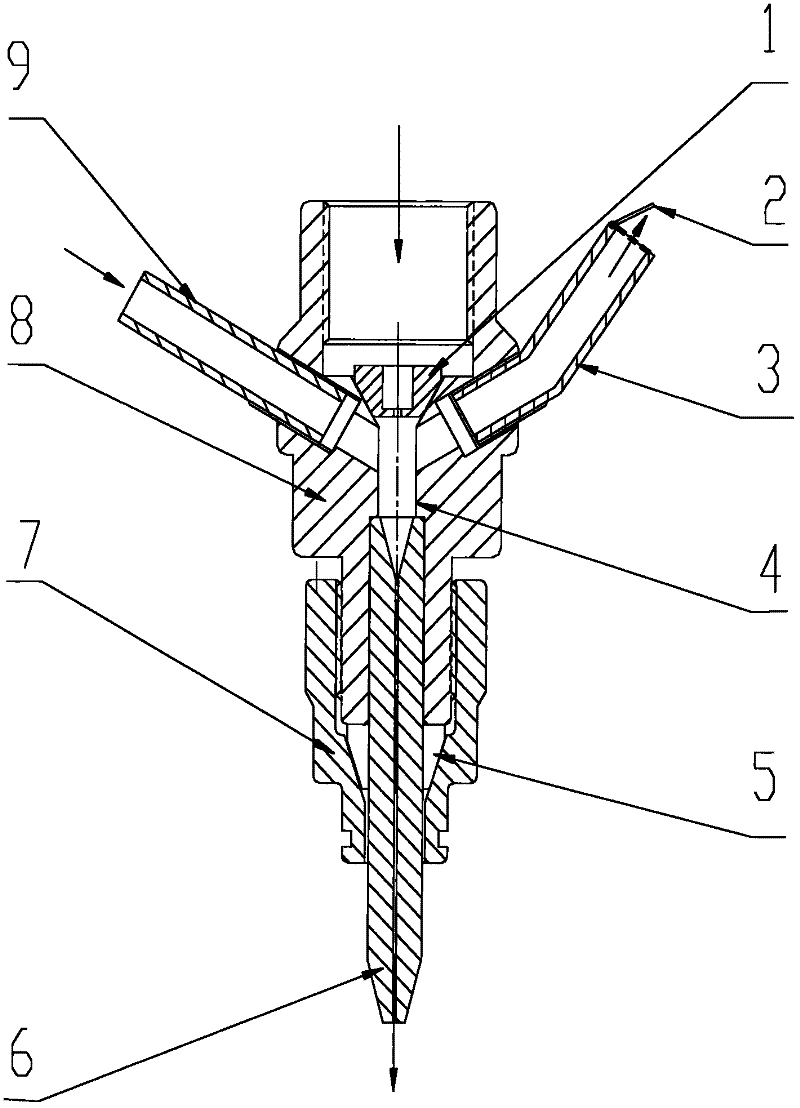

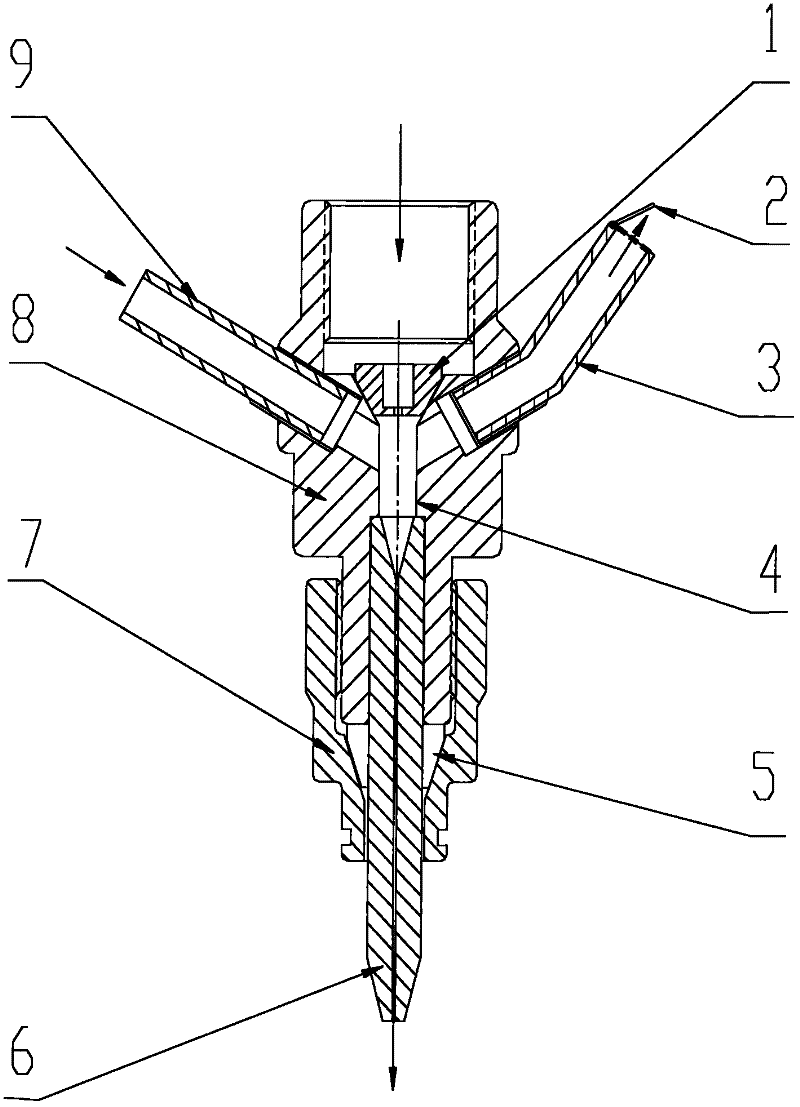

Abrasive water jet cutting spray head device

An abrasive water jet and water jet technology, applied in abrasives, explosion generating devices, spray guns and other directions, can solve the problems of difficult cleaning, damage to the inner wall of the sand nozzle, easy water return, etc., to improve reliability and processing efficiency, improve work efficiency The effect of reliability and ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This embodiment is an abrasive water jet cutting nozzle body, which includes a water jet nozzle 1, a one-way valve cover 2, a cylindrical ring abrasive sand mixing chamber 4, a nozzle body 8, an abrasive sandblasting pipe 6 and an abrasive sand feeding pipe 9. There is a through hole in the center of the nozzle body 8, and one end is a high-pressure water inlet. An abrasive sandblasting tube 6 is installed in the center hole of the other end of the nozzle body 8. The collet 5 is installed at the end of the abrasive blasting tube installation section. And through the compression nut 7, the collet 5, the abrasive blasting pipe 6 and the nozzle body 8 are firmly connected; the water jet nozzle 1 is located in the high-pressure water inlet of the nozzle body. An abrasive sand mixing cavity 4 is formed in the inner hole of the spray head body 8 between the water jet nozzle 1 and the abrasive sandblasting pipe 6 .

[0015] On the shell at the end of the nozzle body 8 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com