Ultrahigh-pressure swirling abrasive water jet drilling machine

An abrasive water jet and ultra-high pressure technology, which is applied in the direction of liquid/gas jet drilling, drill pipe, drill pipe, etc., can solve the problems of hard rock safety, high-efficiency crushing, restrictions on popularization and application, and low reliability. Reduce cutting resistance, improve safety, high pressure water seal simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

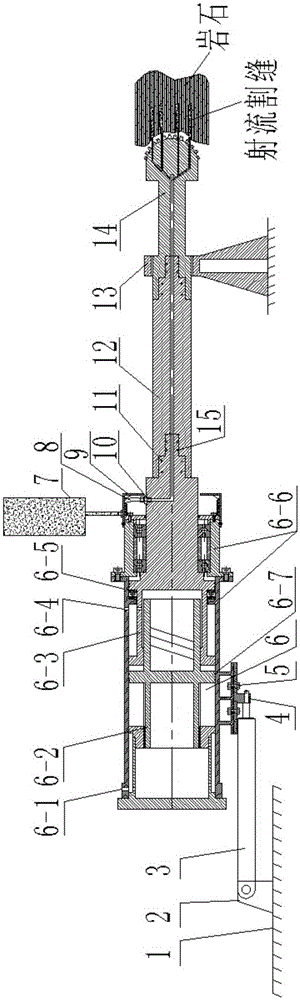

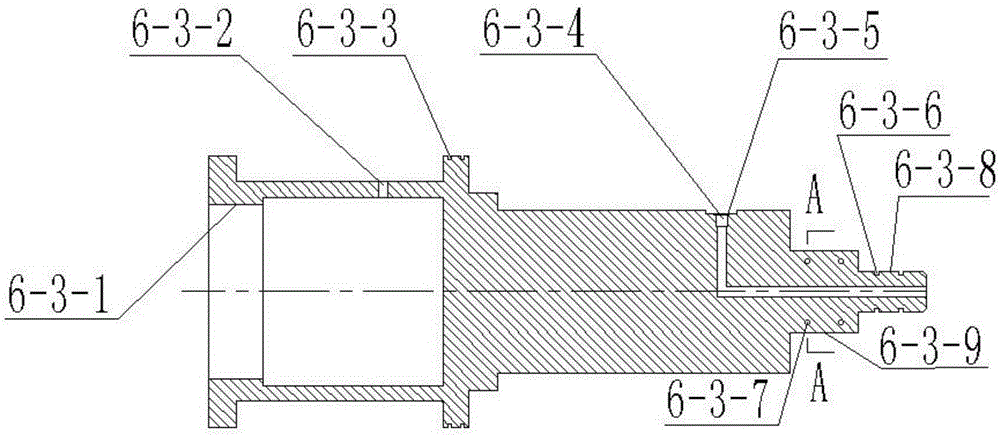

[0024] Such as figure 1 As shown, the ultra-high pressure rotary abrasive water jet drilling machine of the present invention includes a water jet device, a drill bit drive mechanism and a drill bit mechanism. Front hybrid ultra-high pressure abrasive jet system; the drill bit driving mechanism includes a cylinder support seat 2, a propulsion cylinder 3, a rotary oil cylinder 6, a self-retracting high-pressure hose 8 and a hydraulic joint 10, and the drill bit mechanism includes a universal drill rod 12, Drill rod support seat 13 and drill bit 14. The cylinder support seat 2 and the drill pipe support seat 13 are all fixed on the support platform 1, the cylinder body of the propulsion cylinder 3 is hinged with the cylinder support seat 2, the piston rod of the propulsion cylinder 3 is pinned to the connection block 4, and the connection block 4 passes through The bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com