Portable abrasive water jet cutting machine used in coal mine

Abrasive water jet, portable technology, applied in abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problems of inflammability and explosion, and achieve the effect of no gas generation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

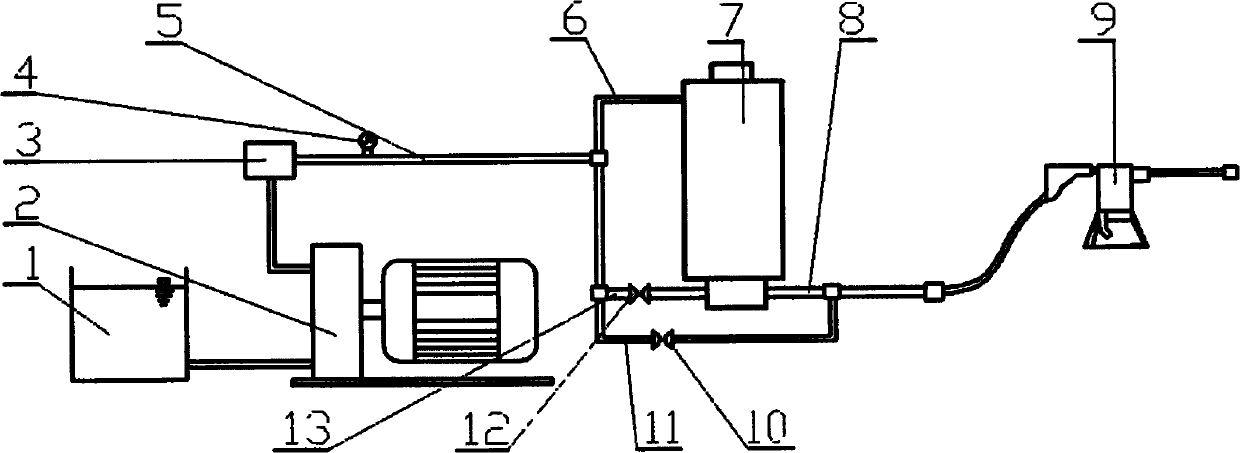

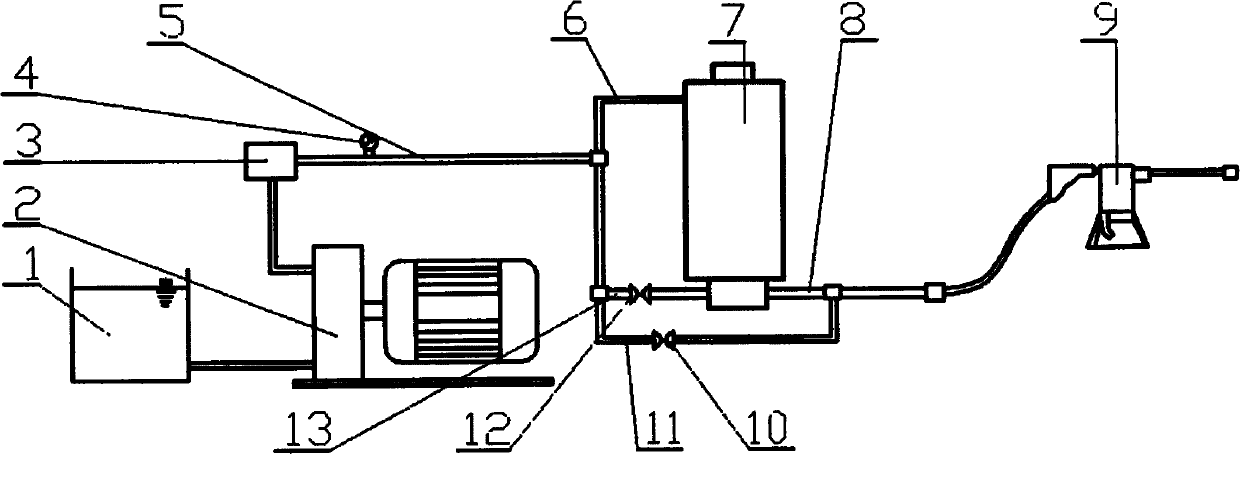

[0010] In the figure, the portable abrasive water jet cutting machine for coal mine includes a water tank 1, a water pump 2, a pressure regulating valve 3, a pressure gauge 4, a water pipe 5, a first branch water pipe 6, a second branch water pipe 13, a third branch water pipe 11, Abrasive amount regulating valve 12, water amount regulating valve 10, abrasive tank 7, mixing pipe 8 and spray gun 9; it is characterized in that: the water tank 1 of the portable coal mine abrasive water jet cutting machine is in the same order as the water pump 2, pressure regulating valve 3, and pressure gauge 4 Connected in series through 5 water pipes, the water pump 2 generates pressure so that the water in the water tank 1 flows through the pressure regulating valve 3 and the pressure gauge 4, and then is divided into three branch water flows, the upper, middle and lower branches, and the water flows respectively to the three branch water pipes divided by the water pipe 5. A branch water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com