Fishbone-shaped anchor rod

An anchor rod and fishbone technology, which is used in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problems of insufficient pull-out resistance, small anchoring depth, and corrosion of anchors, so as to improve durability and reduce Frictional resistance, the effect of improving self-supporting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

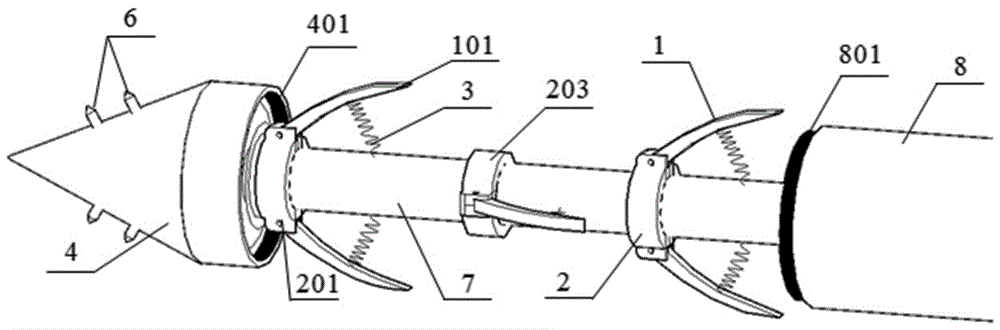

[0042] see figure 1 , a herringbone anchor rod includes an anchor head 4, an anchor rod 7 and a sleeve tube 8; the anchor head 4 is equipped with a movable conical propulsion body 5, and the propulsion body 5 is connected to the anchor rod 7 through the external thread 701 of the anchor rod Front end, the front portion of anchor rod 7 is evenly distributed with grouting holes 702, see Figure 7 ; The anchor head 4 is connected to the front end of the sleeve pipe 8 through the cooperation of the anchor head internal thread 401 and the sleeve pipe external thread 801 .

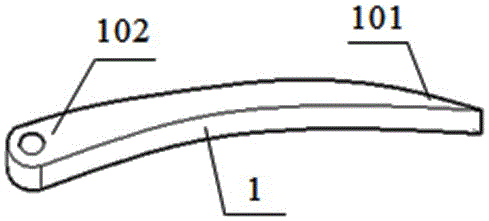

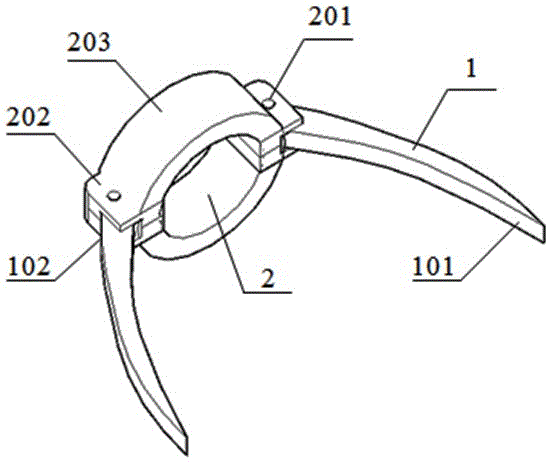

[0043] Two pairs of fishbone-shaped blade mechanisms are evenly distributed on the anchor rod 7 , and the blade mechanisms include blades 1 and clamps 2 . Two pairs of blades are arranged in a staggered manner on the anchor rod 7, and the distance between two adjacent pairs of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com