Quick supporting method for large-deformation roadway easy to fall, break and loosen and apparatus thereof

A large deformation and roadway technology, applied in the direction of tunnels, tunnel linings, bolt installation, etc., can solve problems such as support damage, collapse and falling, sideways movement of two sides, etc., to improve strength and integrity, prevent surrounding rock from loosening, The effect of enhancing self-supporting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

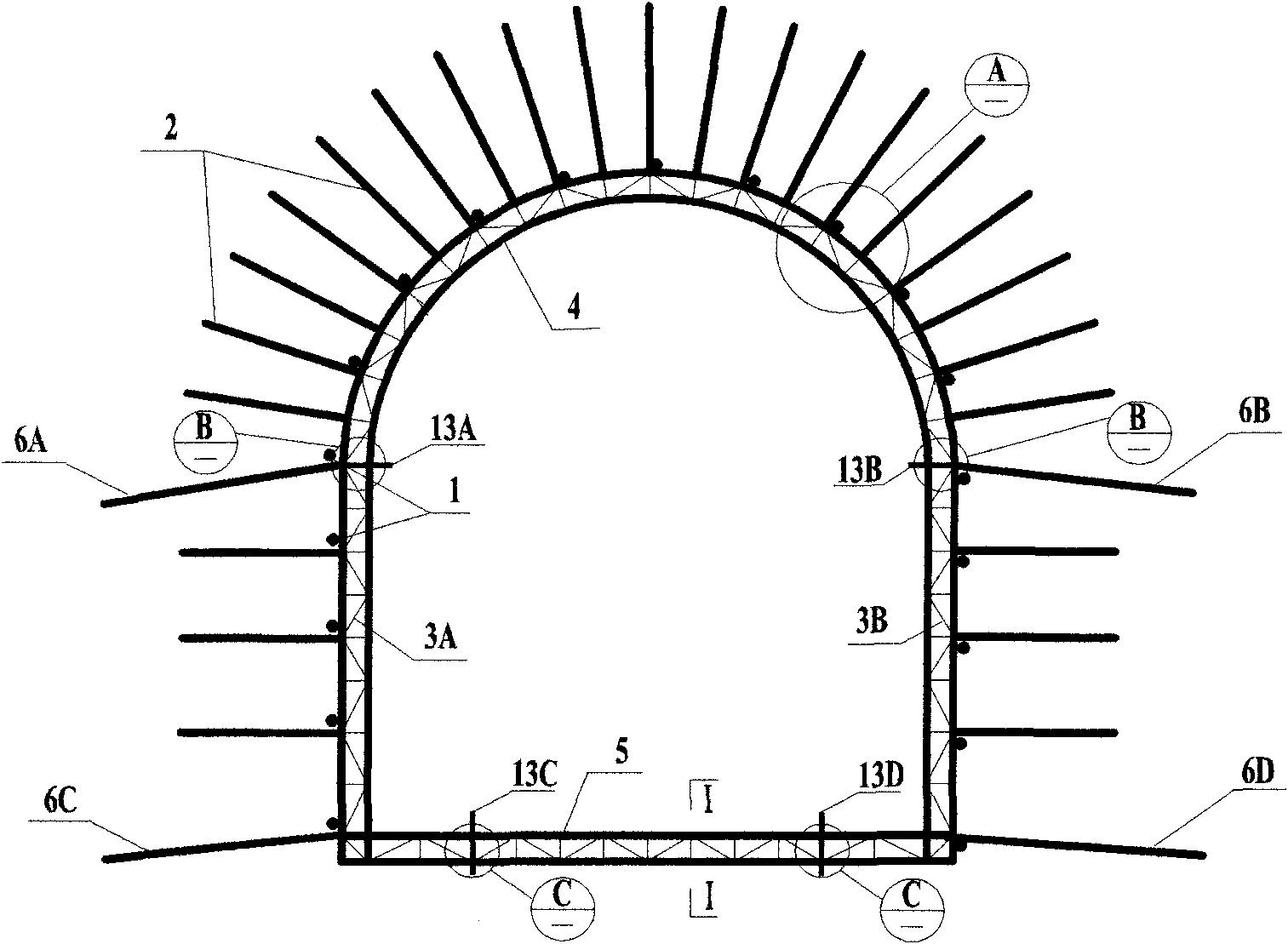

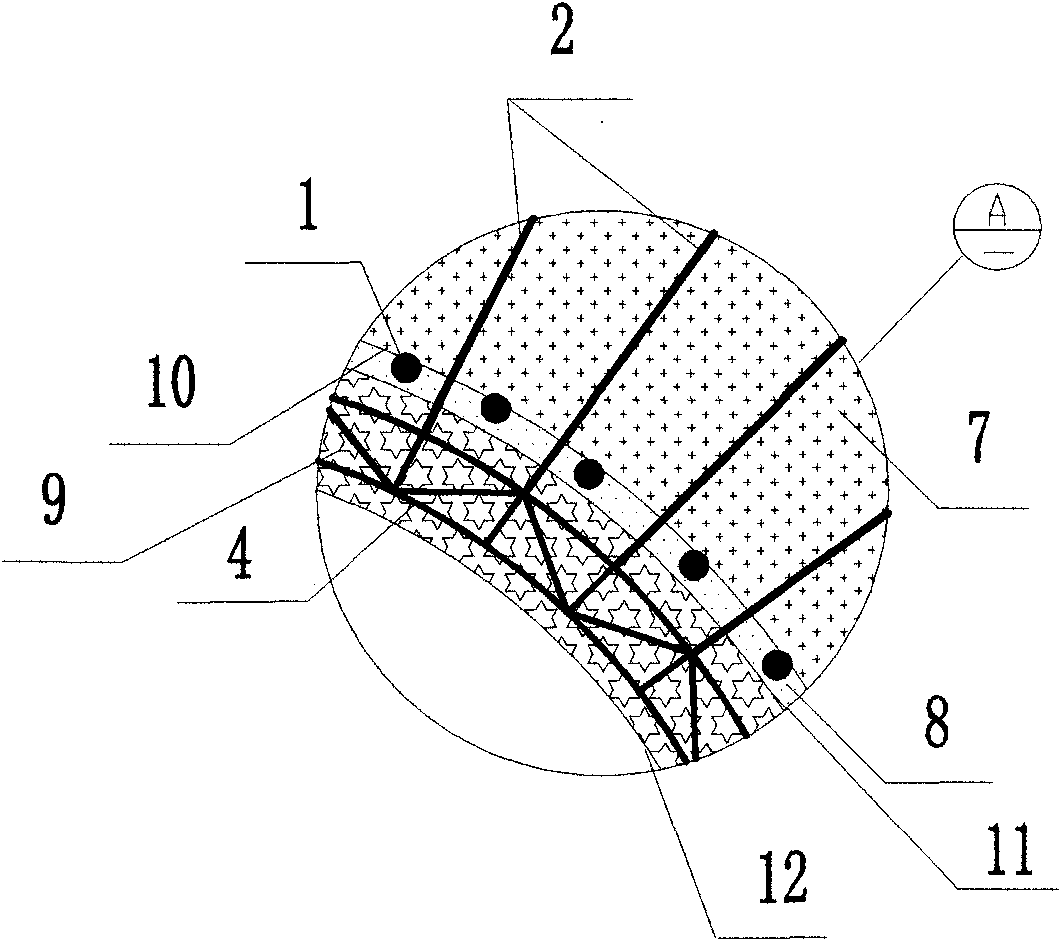

[0067] A rapid support method for a loose roadway with large deformation and easy to fall, the specific implementation steps are:

[0068] Large deformation, easy to fall, broken loose roadway, after each cycle of excavation, stop excavation immediately to support the surrounding rock of the roadway, and the surrounding rock support method of the roadway is realized according to the following steps:

[0069] (1) Remove loose stones on the surrounding rock wall of the roadway to avoid falling off and hurting people during the support process;

[0070] (2) Hang the reinforcement mesh along the excavation contour line of the roadway and initially spray a thin layer of concrete to cover the surrounding rock of the roadway and the reinforcement mesh;

[0071] (3) Drill holes on the roadway wall to install anchor rods, and the exposed length of the anchor rod head should not be less than 20cm;

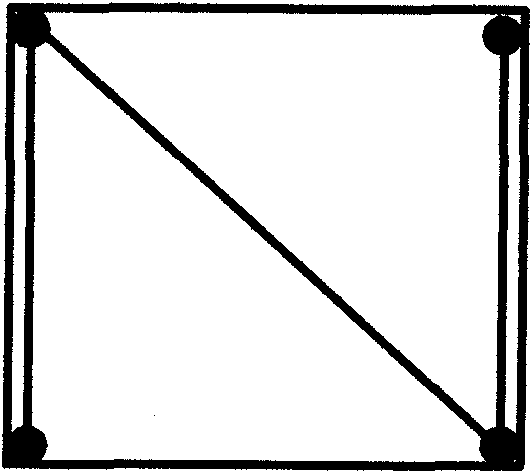

[0072] (4) Install the steel grid arches of the left and right side walls to support th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com