Goaf surrounding rock around gob-side supporting method under three soft geological condition

A technology of geological conditions and gobs, applied in underground chambers, temporary shields, mining equipment, etc., can solve problems such as implementation constraints, achieve simple technology, reduce rock roadway engineering, and eliminate the threat of coal and gas outbursts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

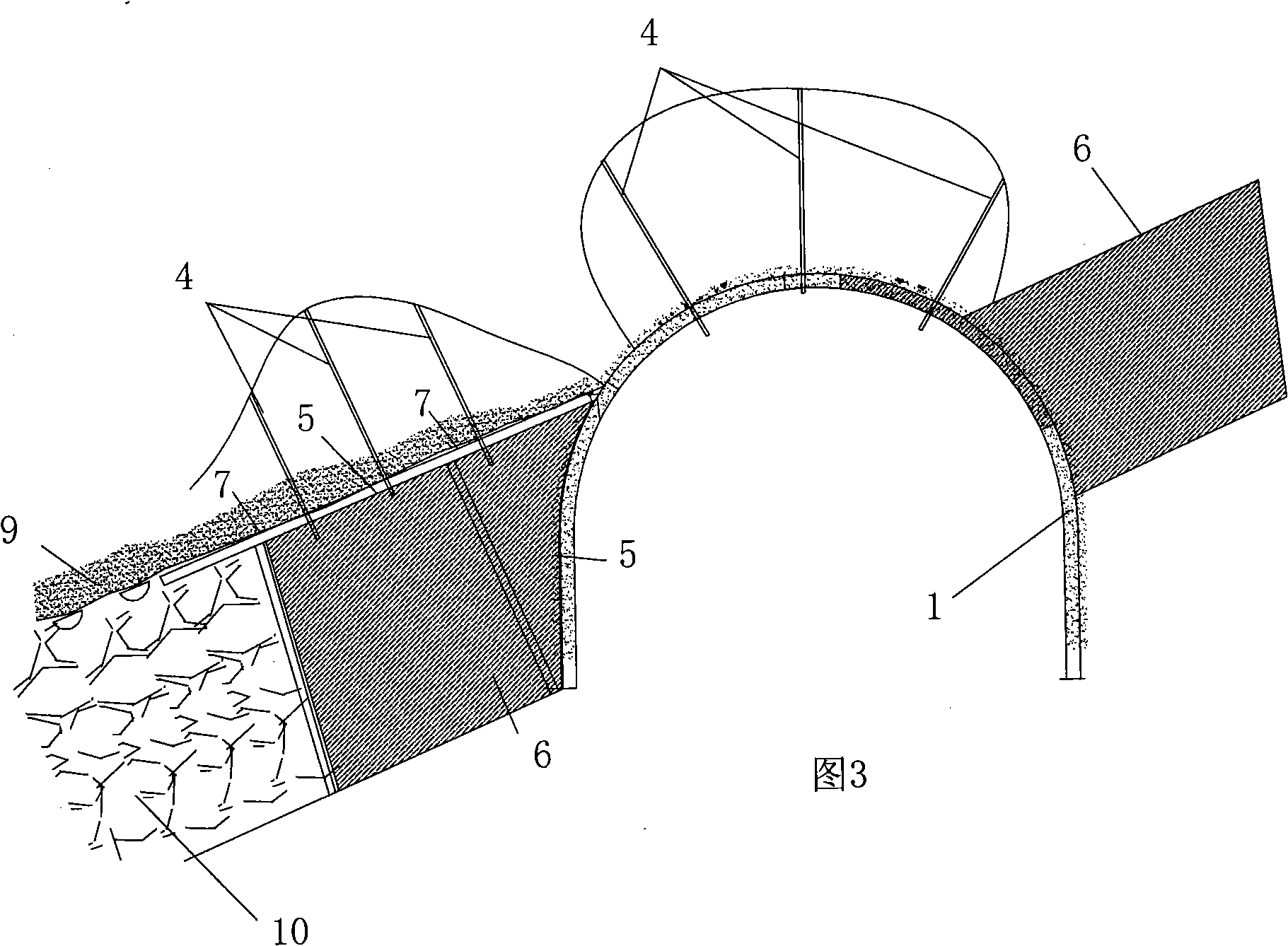

[0039] In this embodiment, the support for the surrounding rock of the gob retaining roadway under the "three soft" geological conditions is carried out as follows:

[0040] 1. Reinforce the lane

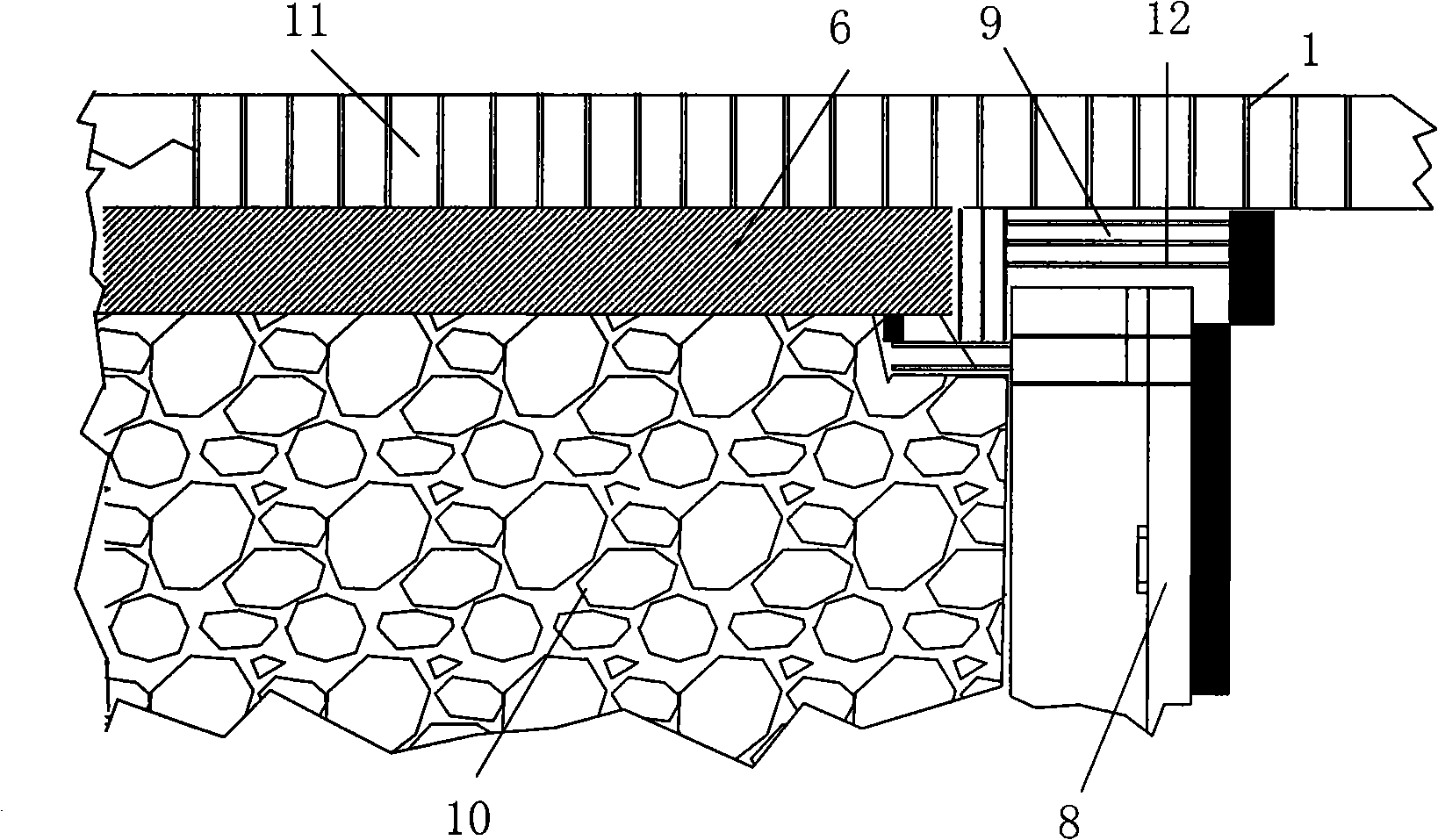

[0041] According to the ventilation requirements, expand the section of the roadway retaining roadway to the two sides and the bottom plate; firstly cover the side of the roadway retaining, and then expand the roadway section. It is required that the expanded section has a reserved deformation. Generally, the two sides are not less than 800mm, and the roof is quite large. 500mm, and meet the ventilation requirements of 8m 2 , it is not allowed to lift the roof during construction;

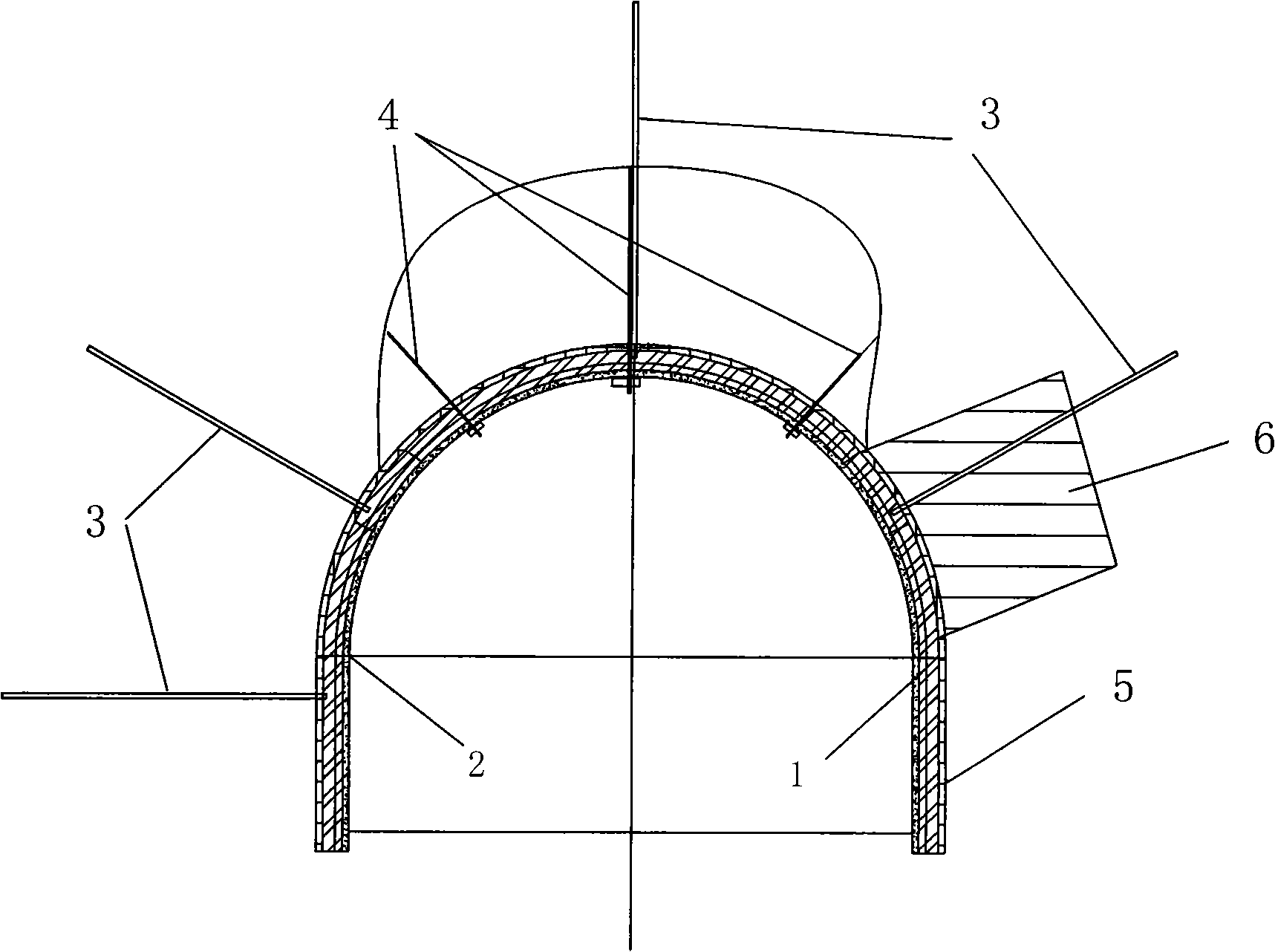

[0042] On the full section of the primary roadway retention, erect shrinkable U-shaped steel sheds 1 at intervals along the roadway direction, and temporarily reinforce and support the roadway to control the deformation of the roadway. The shrinkable U-shaped steel shed 1 can be deformed without damage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com