Electric furnace flue gas waste heat recovering and temperature regulating device

A flue gas waste heat and temperature adjustment device technology, which is applied to furnace control devices, furnaces, waste heat treatment, etc., can solve problems such as burst pipe leakage, reduce investment, and improve operational safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific examples.

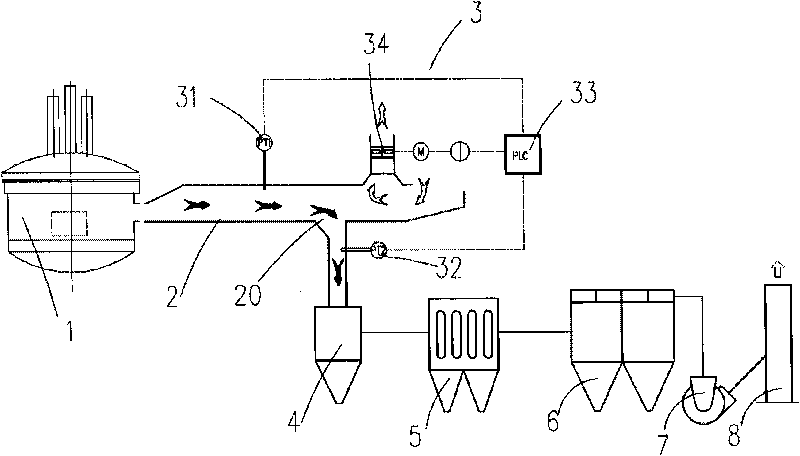

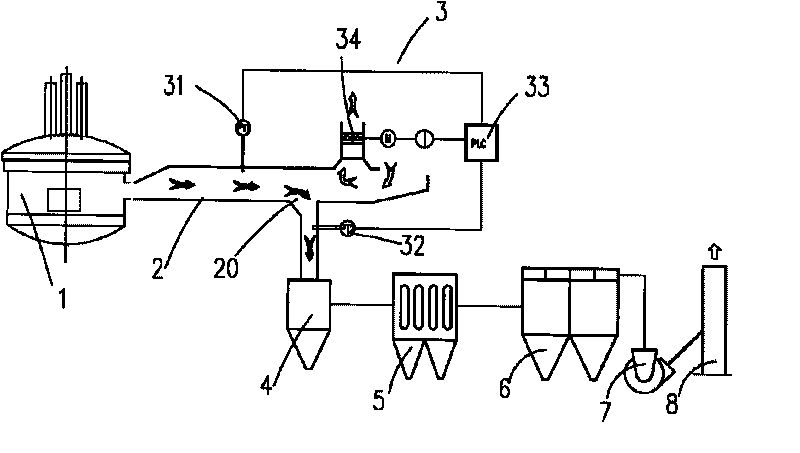

[0009] Please refer to figure 1 As shown, an electric furnace flue gas waste heat recovery temperature adjustment device includes an electric furnace 1, a scrap steel preheating passage 2 connected to the electric furnace, a settling chamber 4 connected to the preheating passage, and waste heat recovery equipment 5 sequentially connected to the settling chamber , dust collector 6, dust removal fan 7 and exhaust cylinder 8; a temperature control device 3 is provided between the scrap steel preheating passage 2 and the settling chamber 4, and the temperature control device 3 includes a The first temperature sensor 31 between, the second temperature sensor 32 that is arranged between the preheating channel 2 and the settling chamber 4, the PLC control system 33 that is arranged between the first and second temperature sensors, and the PLC control system Connected frequency conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com