Dust removal sedimentation device

A technology of sedimentation device and dust removal bucket, which is applied in the direction of filtration circuit, use of liquid separation agent, filtration separation, etc., can solve the problems of transformation, reduction of dust removal effect, environmental pollution, etc., to ensure dust removal effect, reduce water consumption, and prevent waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

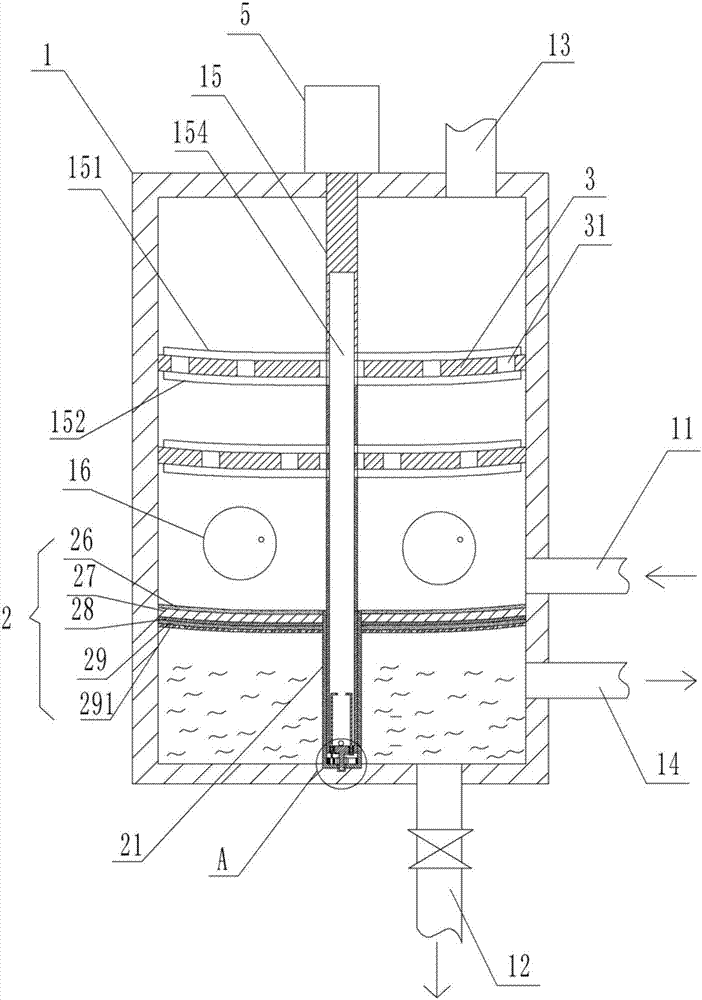

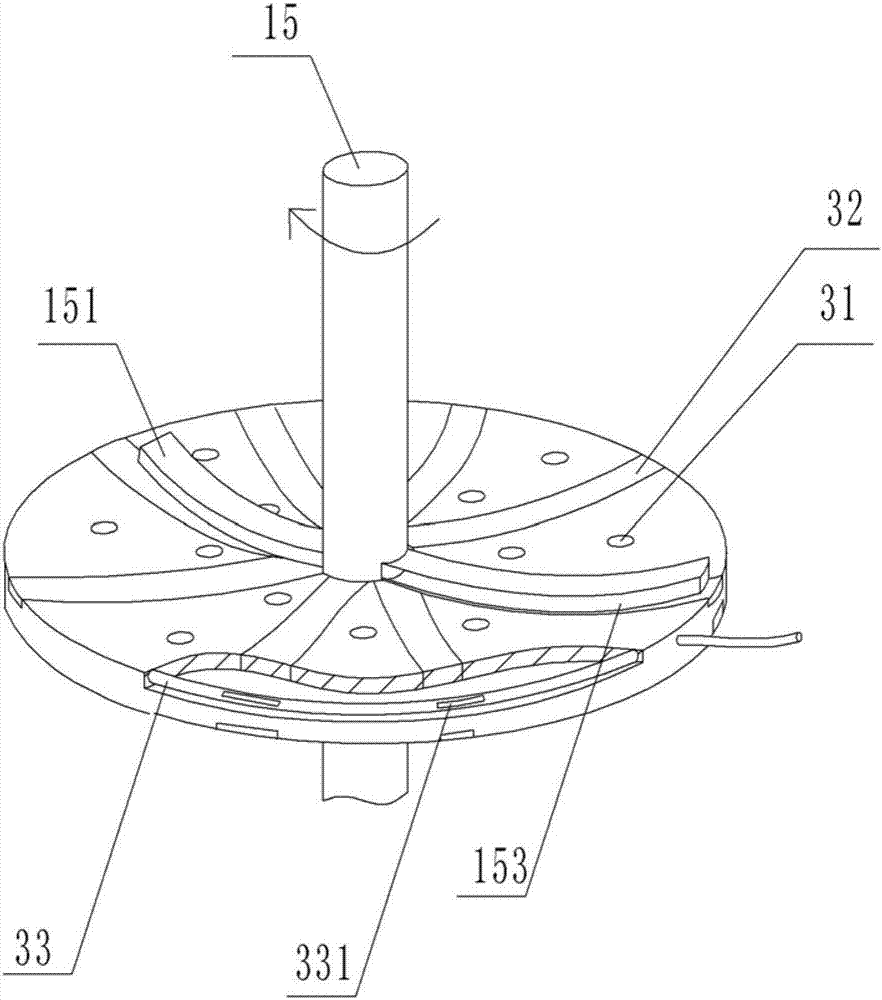

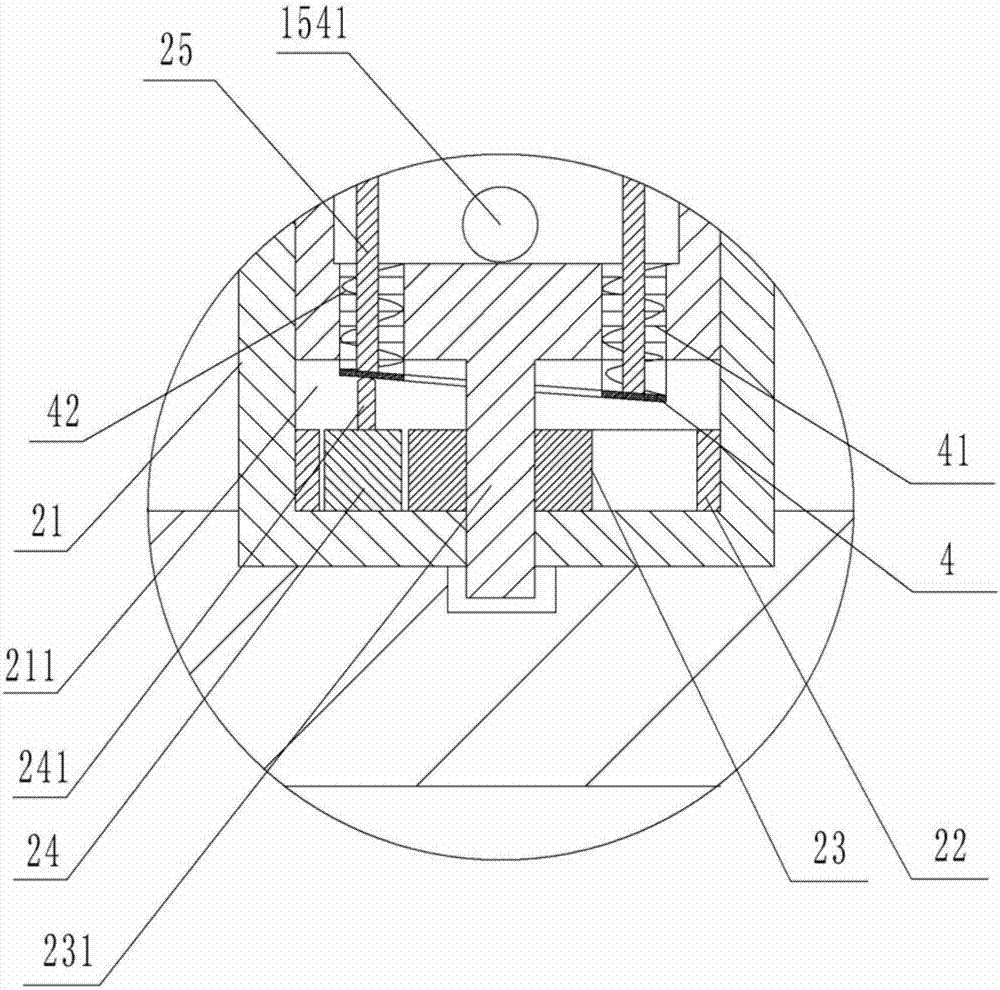

[0029]The reference signs in the accompanying drawings of the specification include: dust removal bucket 1, air intake pipe 11, sewage outlet pipe 12, exhaust pipe 13, clear liquid discharge pipe 14, rotating shaft 15, upper scraping strip 151, lower scraping strip 152, scraping groove 153 , sewage cavity 154, discharge port 1541, cleaning port 16, filter plate 2, support column 21, power chamber 211, inner ring gear 22, driving gear 23, rotating rod 231, driven gear 24, pushing rod 241, stirring rod 25 , carbon layer 26, sand layer 27, gravel layer 28, cotton cloth layer 29, filter screen plate 291, dust removal plate 3, air hole 31, water absorption layer 32, annular water pipe 33, insertion port 331, fixed ring 4, rubber cover 41, spring 42, motor 5.

[0030] Such as figure 1 , figure 2 and image 3 As shown, the dust removal and precipitation device includes a du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com