Air quantity automatic regulating method of variable working condition ventilating system

A ventilation system and automatic adjustment technology, applied in heating and ventilation control systems, heating and ventilation safety systems, space heating and ventilation, etc., can solve the problems of automatic control of fan parameters, poor dust collection effect at dust collection points, and pipe network characteristics Changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

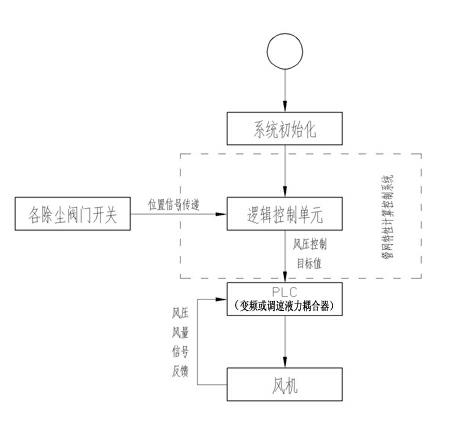

[0016] Embodiment 1, using a simple pipe network characteristic calculation control system, refer to the attached figure 1 .

[0017] The method for automatic adjustment of the air volume of the ventilation system under variable working conditions, the specific steps are as follows:

[0018] First input the information of the dust removal pipe network (such as: pipe diameter of each node, elbow, tee, valve, dust collection cover, etc.) and the required air volume of each dust collection point into the computer dust removal pipe network characteristic simulation calculation software; computer dust removal pipe network characteristics The simulation calculation software is a simulation calculation software for pipe network characteristics using a PC platform, which can calculate the air volume, wind speed, dynamic wind pressure, static wind pressure, and Resistance, local resistance and other information can simulate the distribution of wind pressure and air volume in the pipe ...

Embodiment 2

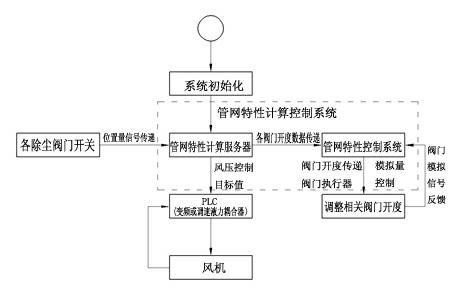

[0021] Embodiment 2, using the precise pipe network characteristic calculation control system, refer to the attached figure 2 .

[0022] Since accurate adjustment requires real-time dynamic simulation of the characteristics of the pipe network, secondary adjustments are made to the dust removal pipe network to redistribute local resistance to achieve precise air volume adjustment; therefore, the control requirements of this embodiment are complicated, and the pipe network characteristic calculation control system in this embodiment consists of The pipe network characteristic calculation server and the pipe network characteristic control system are composed; the pipe network characteristic calculation server realizes the real-time simulation calculation of the change of the dust removal pipe network condition, and determines the minimum main pipeline pressure and Air volume parameters, and pass these parameters to the frequency converter or speed-regulating hydraulic coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com