Online leak finding method for bag filter

A bag filter and bag technology, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of long leak detection time, small damage to the cloth bag, and inability to accurately detect leaks, thereby reducing manpower, material resources and cost. Waste of financial resources, high efficiency and precision in catching leaks, and the effect of avoiding production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described below with reference to the drawings.

[0018] The bag filter is a black box. It is a working container where the gas with particulate dust is filtered and purified by a bag filter bag to achieve a certain proportion of air-ash separation. Under normal circumstances, the inside of the bag filter cannot be observed directly, and its state can only be estimated by measuring and calculating by means of pressure and other testing methods.

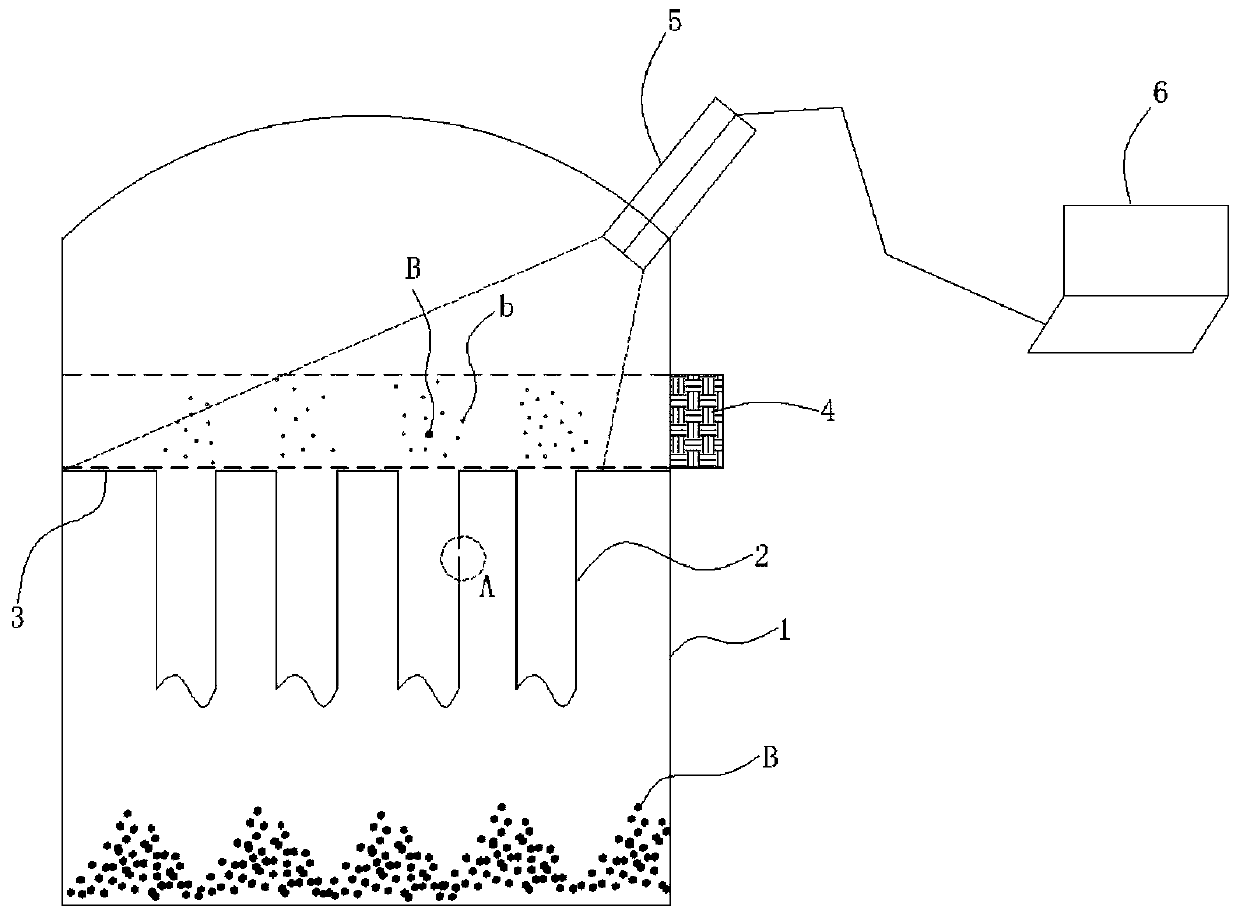

[0019] Such as figure 1 As shown, the bag filter includes a dust collector cylinder 1, a number of bag filter bags 2 and a flower plate 3. Several cloth bag filter bags 2 are arranged in the dust collector cylinder 1, and the top ends are installed on the flower plate 3.

[0020] The invention provides an online leak catching method of a bag filter, which is a method for catching leaks of a bag filter without stopping the machine. The method includes setting the light source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com