Workpiece grinding dust remover

A technology for dust collectors and workpieces, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. It can solve the problems of lack of cleaning mechanism for filter bags, reduced dust removal effect, poor isolation and protection effect, etc., and achieves obvious environmental air quality. , Environmental air quality improvement, the effect of protecting safety and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

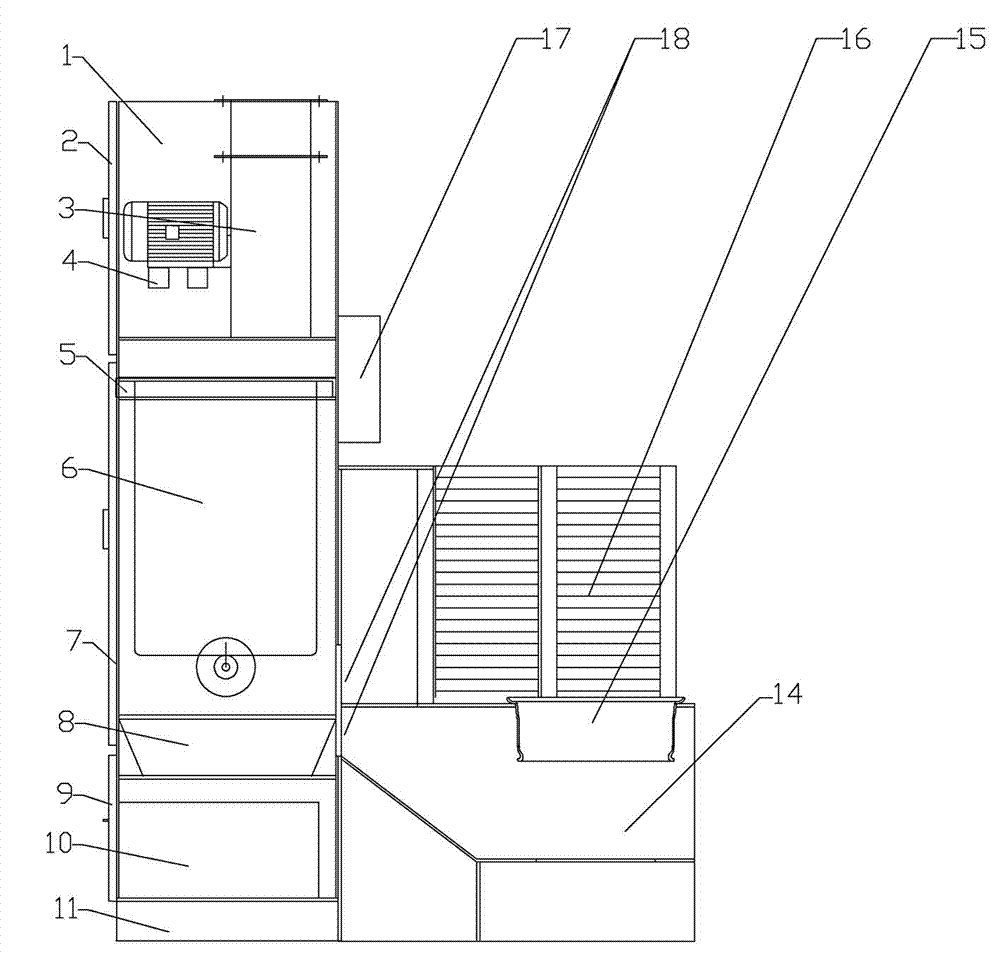

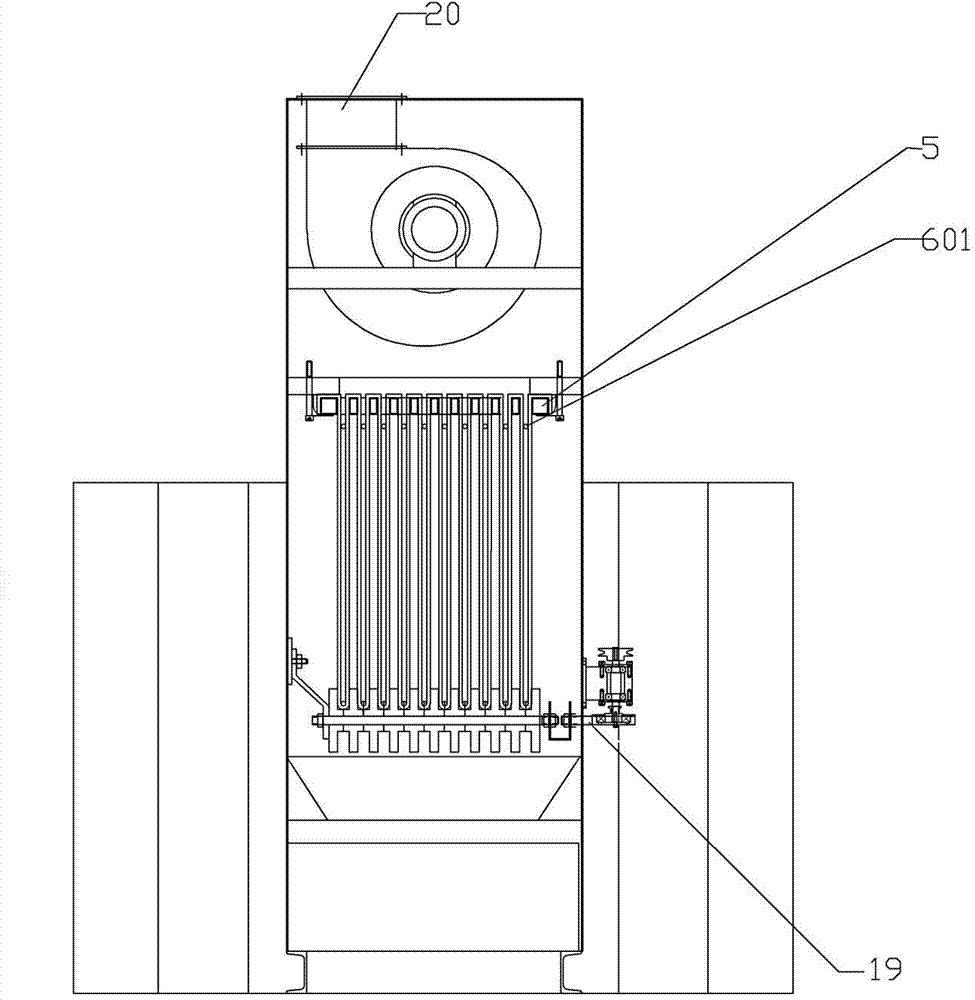

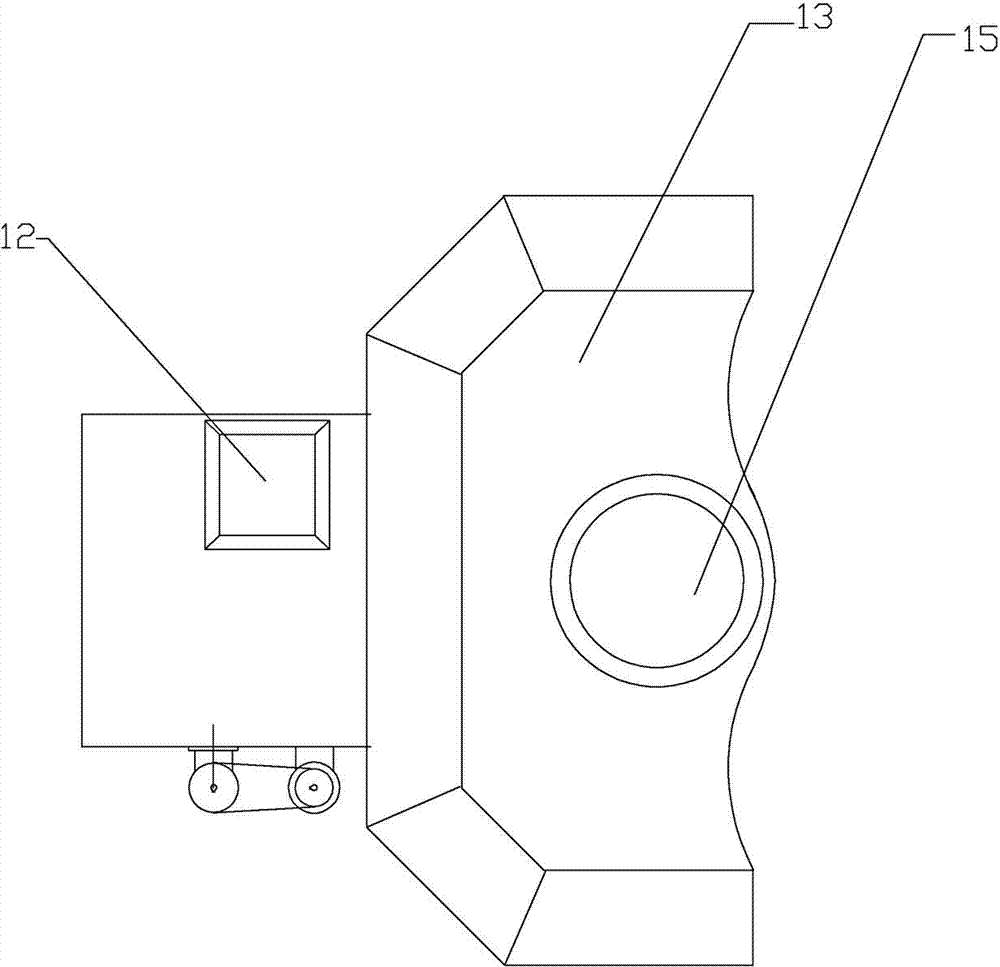

[0022] Such as figure 1 , figure 2 , image 3 As shown, a kind of workpiece grinding and dedusting machine provided by the present invention includes a grinding platform 13 and a dust removal device connected together, the center of the grinding platform 13 is provided with a workpiece positioning hole 15, the inner edge of the grinding platform 13 and The two sides are provided with continuous grilles 16, combined with Figure 5 As shown, the grille 16 is composed of several layers of horizontal and downwardly inclined grilles. The air inlet opening of the grille 16 is facing downward. The inside of the grille 16 is a through dust-containing air chamber 14. The dust removal device includes The dust air inlet 18 and the housing 1 of the air outlet 20, the housing 1 is equipped with a fan 3, a filter bag hanger 5, a filter bag 6, an ash hopper 8, an ash drawer 10, and a filter bag 6 from top to bottom. The integral bag with continuous serpentine coils is adopted. The filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com