Processing device for plank

A technology of processing device and wood board, applied in spraying device, cleaning method using gas flow, cleaning by electrostatic method, etc., can solve the problem of inability to adjust the spraying range of the spraying head, and achieve the effect of comprehensive and effective spraying and enhancing practical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

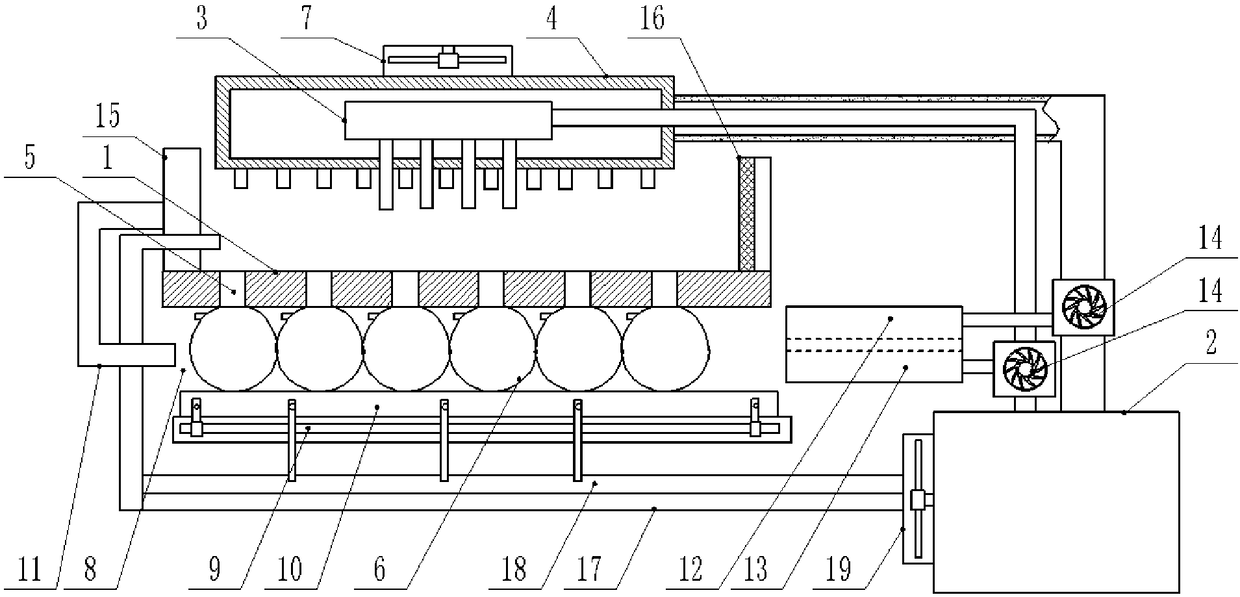

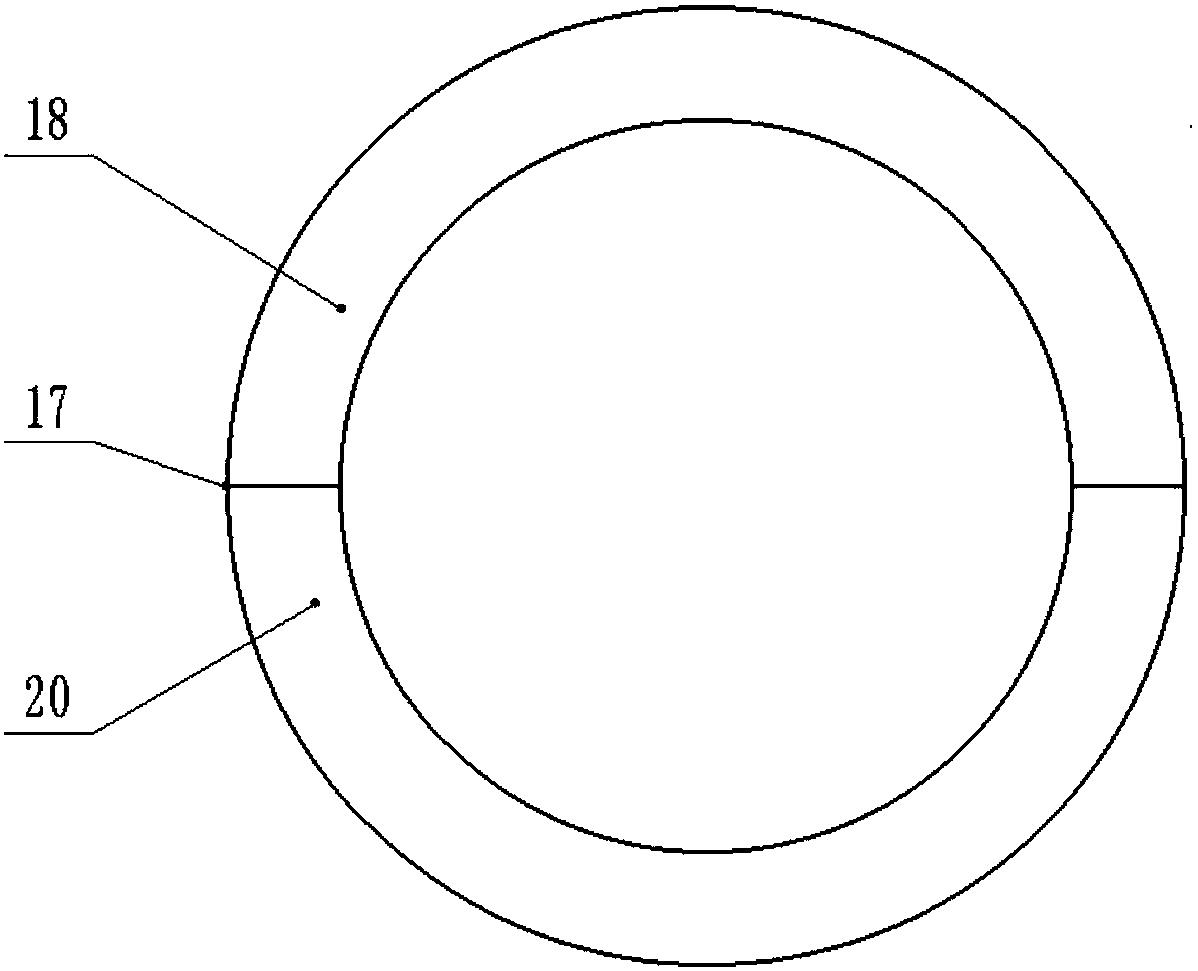

[0017] The reference signs in the accompanying drawings of the specification include: transfer table 1, paint box 2, main nozzle 3, auxiliary nozzle 4, through hole 5, air bag 6, blower 7, air flow channel 8, chute 9, shrapnel 10, air inlet pipe 11. Upper air outlet pipe 12, lower air outlet pipe 13, impeller 14, baffle plate 15, dust suction plate 16, dust removal pipe 17, elastic surface 18, fan 19, fixed surface 20.

[0018] Example figure 1 Shown: Processing device for wooden boards, including conveyor table 1, air-flow driven painting mechanism, air-flow control mechanism and dust removal mechanism.

[0019] The transfer table 1 is used to place the planks to be processed. The top of the transfer table 1 is provided with a blower 7 . Both ends of the conveyor table 1 are provided with baffles 15, wherein one side of the baffle 15 is provided with a cavity and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com