Sound insulation module on sound insulation apparatus of large noise equipment

A sound insulation device and equipment technology, applied in the direction of sound-generating equipment, instruments, etc., to achieve obvious sound insulation effect, simple structure, and improve the effect of sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

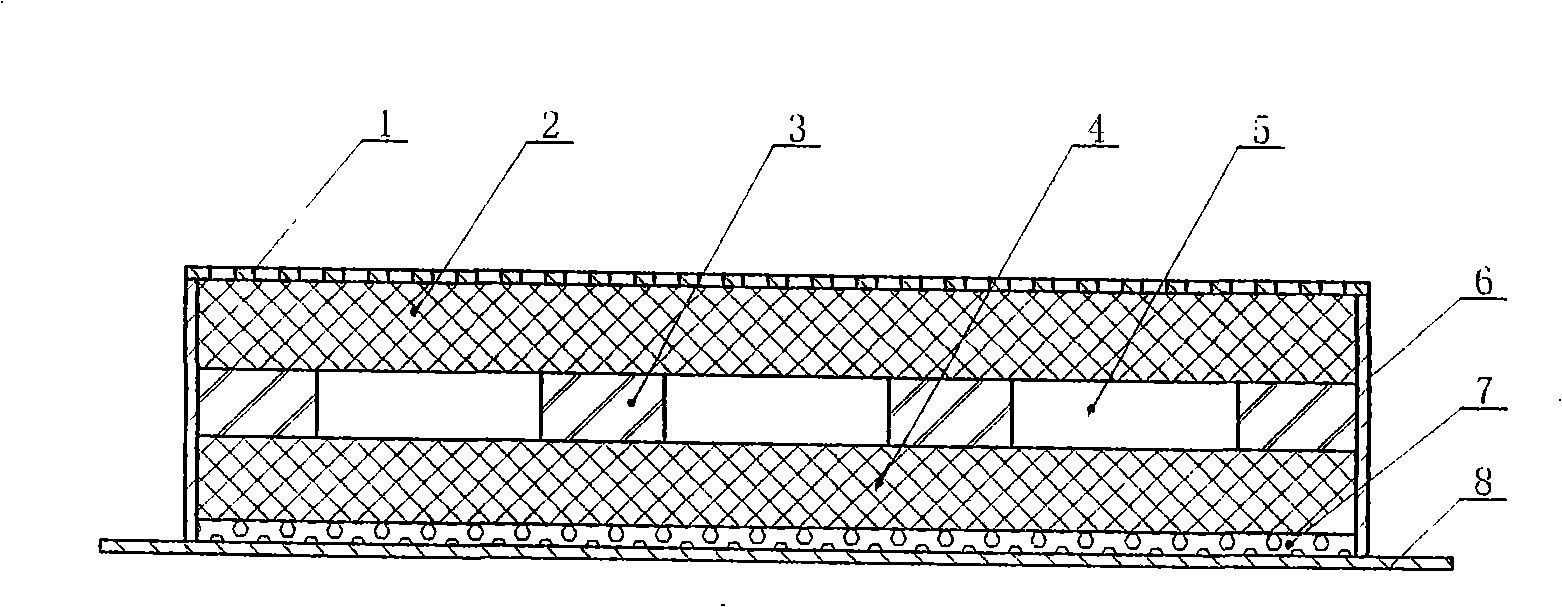

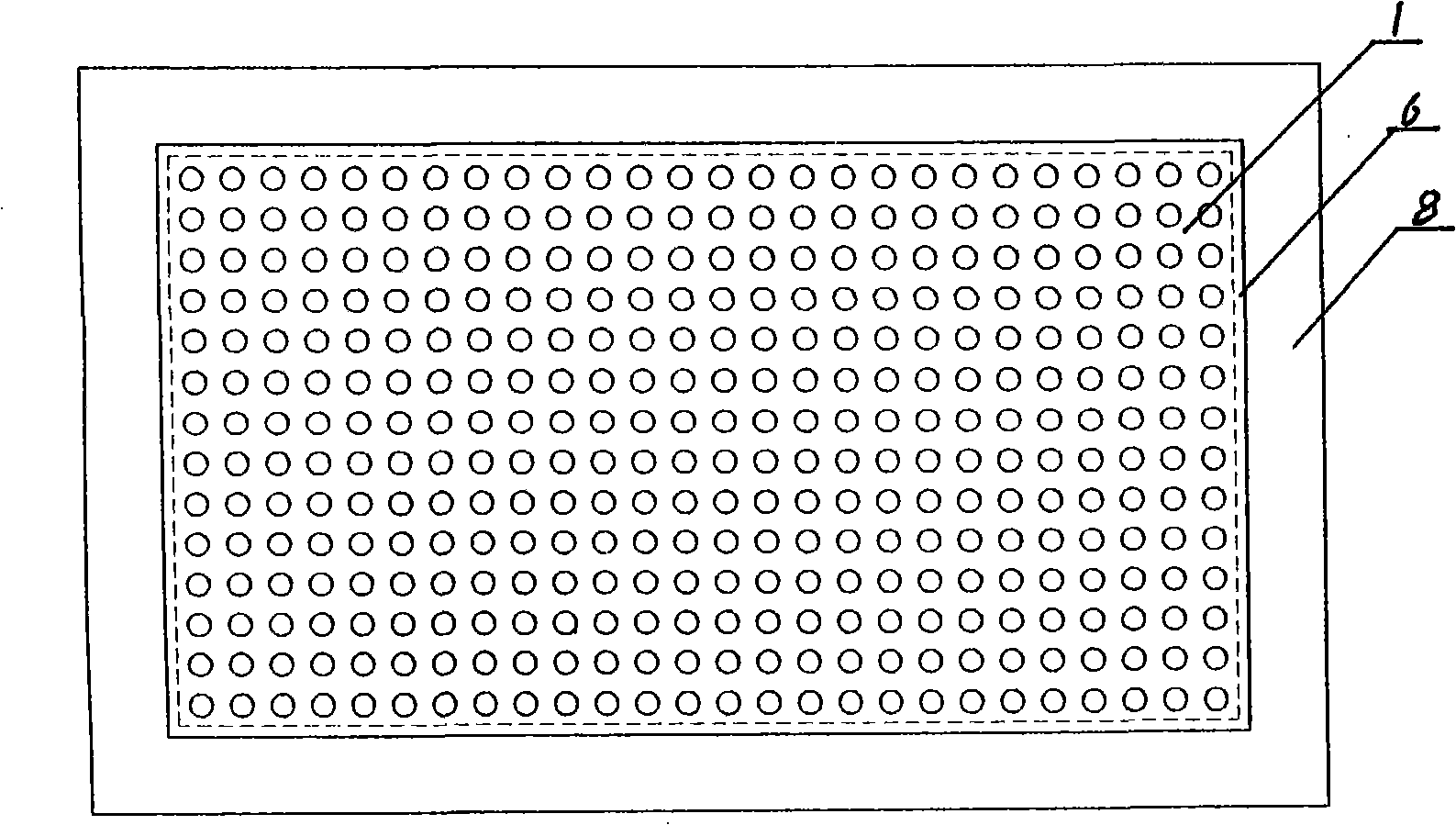

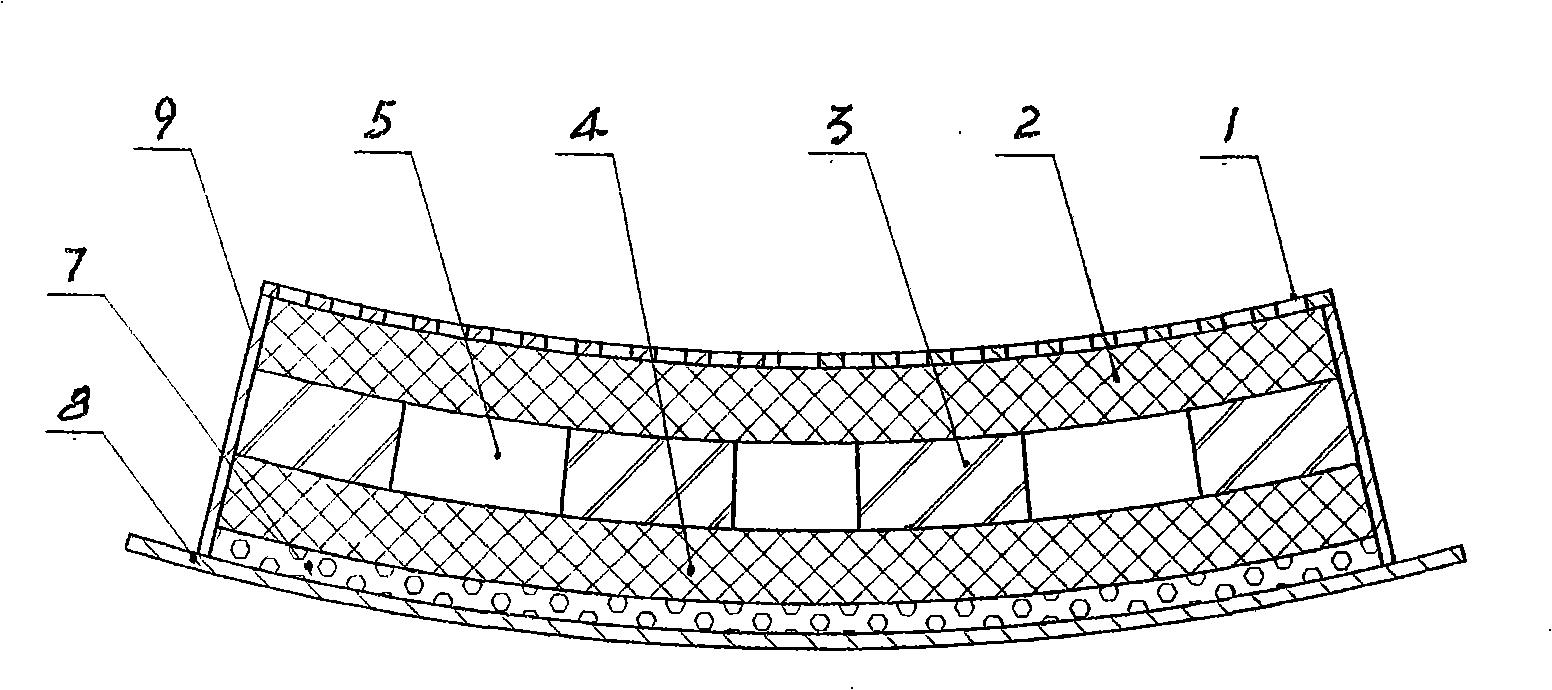

[0013] refer to figure 1 , the present invention is a sound insulation module on the sound insulation device of loud noise equipment, the module consists of a sound insulation board 8, a damping and vibration reduction layer 7, and a sound-absorbing cotton board 4 from the outer layer to the inside; 1. Sound-absorbing cotton board 2; the module is surrounded by ribs 6 perpendicular to the perforated sound-absorbing steel plate and the sound-insulating board. The feature is that a layer of sound-insulating cotton felt 3 and rectangular The sound returns to cavity 5.

[0014] The present invention mainly is divided into two kinds of plane type and circular arc (as figure 1 and image 3 ).

[0015] The sound-absorbing cotton board 2 on the inner side of the present invention is made of dense sizing cotton board with good sound-absorbing effect, and the sound-absorbing cotton board 4 is made of loose cotton board with good sound-absorbing effect, and the middle layer of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com