Perforated plate resonance sound absorption device possessing built-in cavity

A resonant sound absorption and perforated plate technology, applied in the field of sound absorption and noise reduction, can solve the problems of decreased structural surface strength, insufficient sound absorption frequency band, secondary pollution, etc. Sound Band Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

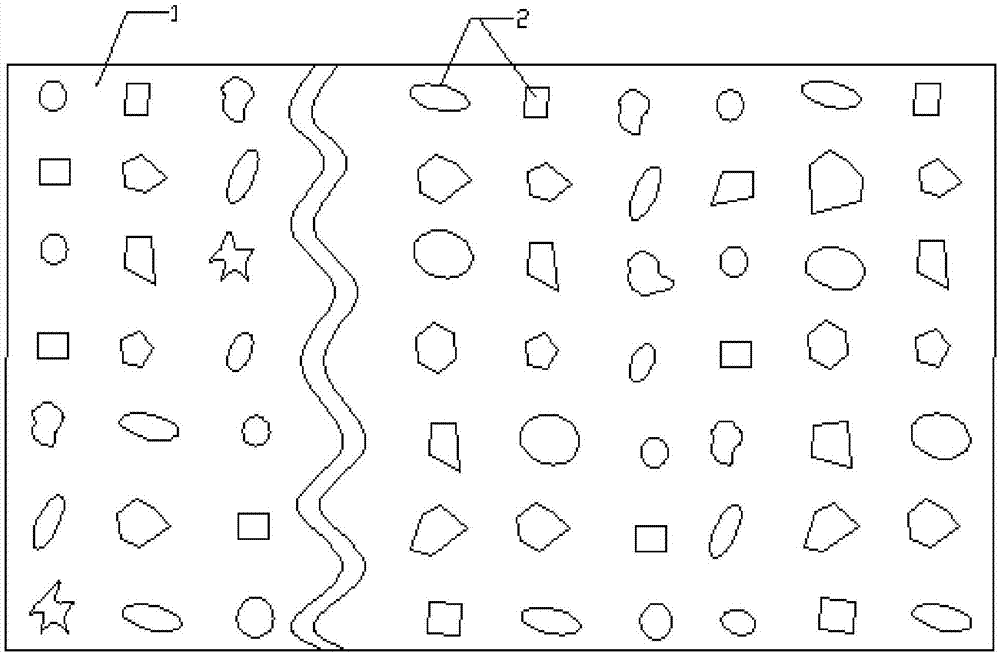

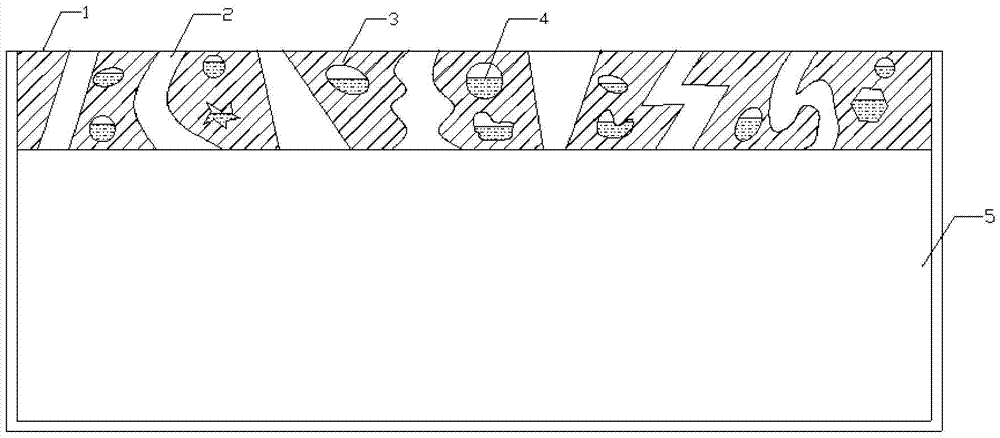

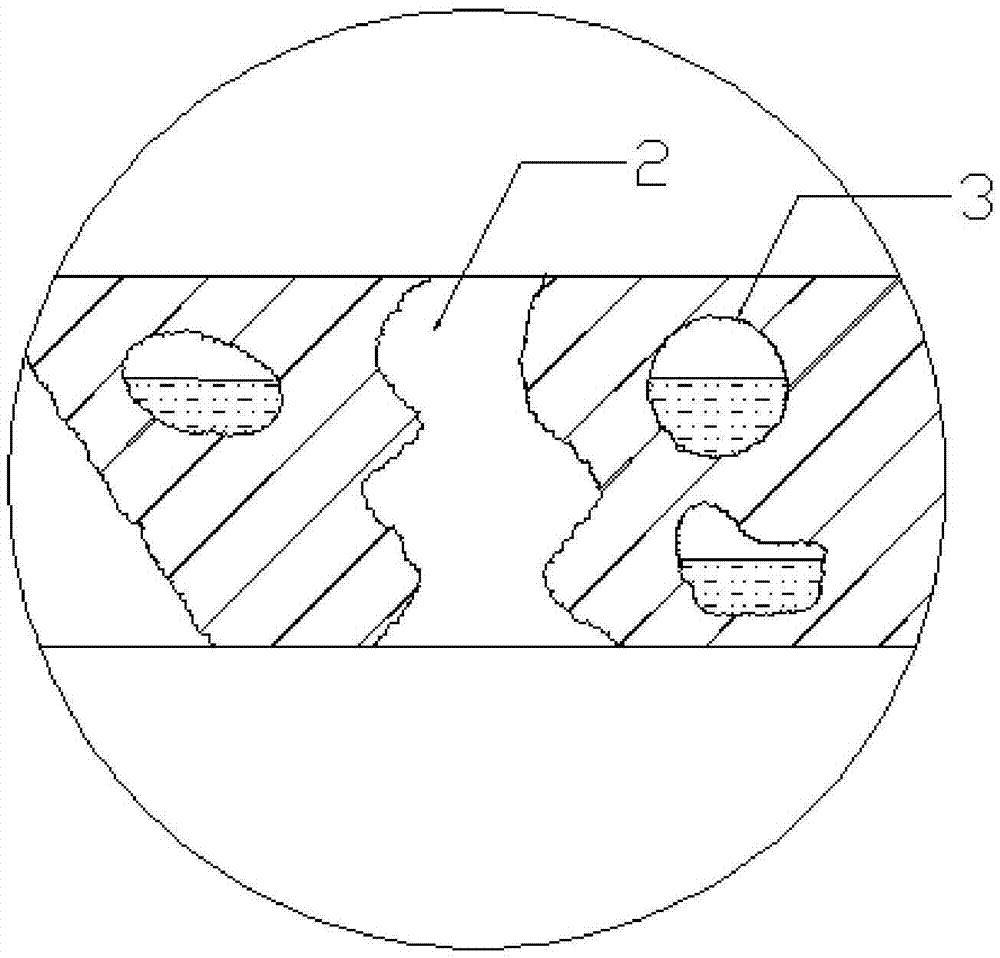

[0038] Embodiment 1: A perforated plate with straight through holes is provided with a cavity, and a resonant sound-absorbing device in which water is injected into the cavity;

Embodiment 2

[0039] Embodiment 2: A perforated plate with straight through holes is provided with a cavity, and the cavity is filled with a resonant sound-absorbing device with a rubber particle size of 1.0 mm;

Embodiment 3

[0040] Embodiment 3: A perforated plate with straight through holes is provided with a cavity, and water and rubber particles with a particle size of 1.0 mm are injected into the cavity for a resonance sound absorption device;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com