High molecular particle composite sound absorbing material, its mfg. method and uses

A technology of polymer particles and polymer materials, which is applied in the field of polymer particle composite sound-absorbing materials and their preparation, to achieve high absorption strength, broaden the sound-absorbing frequency band, and improve the mid-low frequency sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

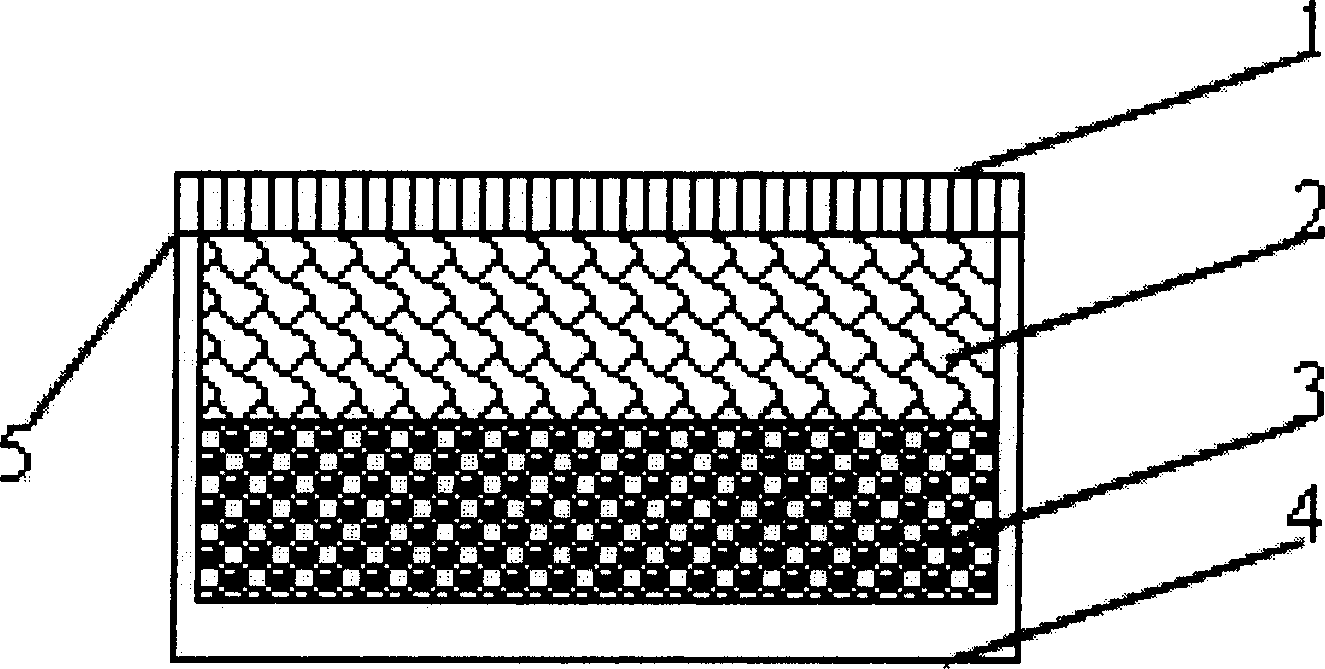

[0030] The average particle size is 1000 μm, and the particle layer thickness is 30mm polypropylene particle layer 3; the apparent density is 85kg / m 3 , a polyurethane (PU) foam porous layer 2 with a thickness of 5mm; the perforated aperture is 3.5mm, the porosity is 1.8%, and the polyvinyl chloride (PVC) perforated layer 1 with a thickness of 3mm; the gradient is put into the plastic mold box 4 successively The periphery of the mold box and the surface layer of the polymer material are bonded together with an adhesive.

Embodiment 2

[0032] The average particle size is 150 μm, and the particle layer thickness is 20mm waste rubber powder particle layer 3; the apparent density is 15kg / m 3 , a polyethylene (PE) foam porous layer 2 with a thickness of 10mm; the perforated aperture is 5mm, the porosity is 1.75%, and the polyvinyl chloride (PVC) perforated layer 1 with a thickness of 1mm; the gradient is put into the plastic mold box 4 successively The periphery of the mold box and the surface layer of the polymer material are bonded together with an adhesive.

Embodiment 3

[0034] The polysiloxane particle layer 3 with an average particle size of 250 μm and a particle layer thickness of 10 mm; an apparent density of 67.5 kg / m 3 , a polyurethane (PU) foam porous layer 2 with a thickness of 15mm; the perforated aperture is 10.5mm, the porosity is 10.65%, and the thickness is a polypropylene (PP) perforated layer 1 with a thickness of 12mm; the gradient is put into the plastic mold box 4 successively, The periphery of the mold box and the periphery of the surface layer of the polymer material are bonded into a whole with an adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com