Macromolecular composite foam material as well as preparation method and application thereof

A composite foam and polymer technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems that the sound insulation effect of composite materials cannot be improved, and achieve the improvement of sound absorption coefficient and sound absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

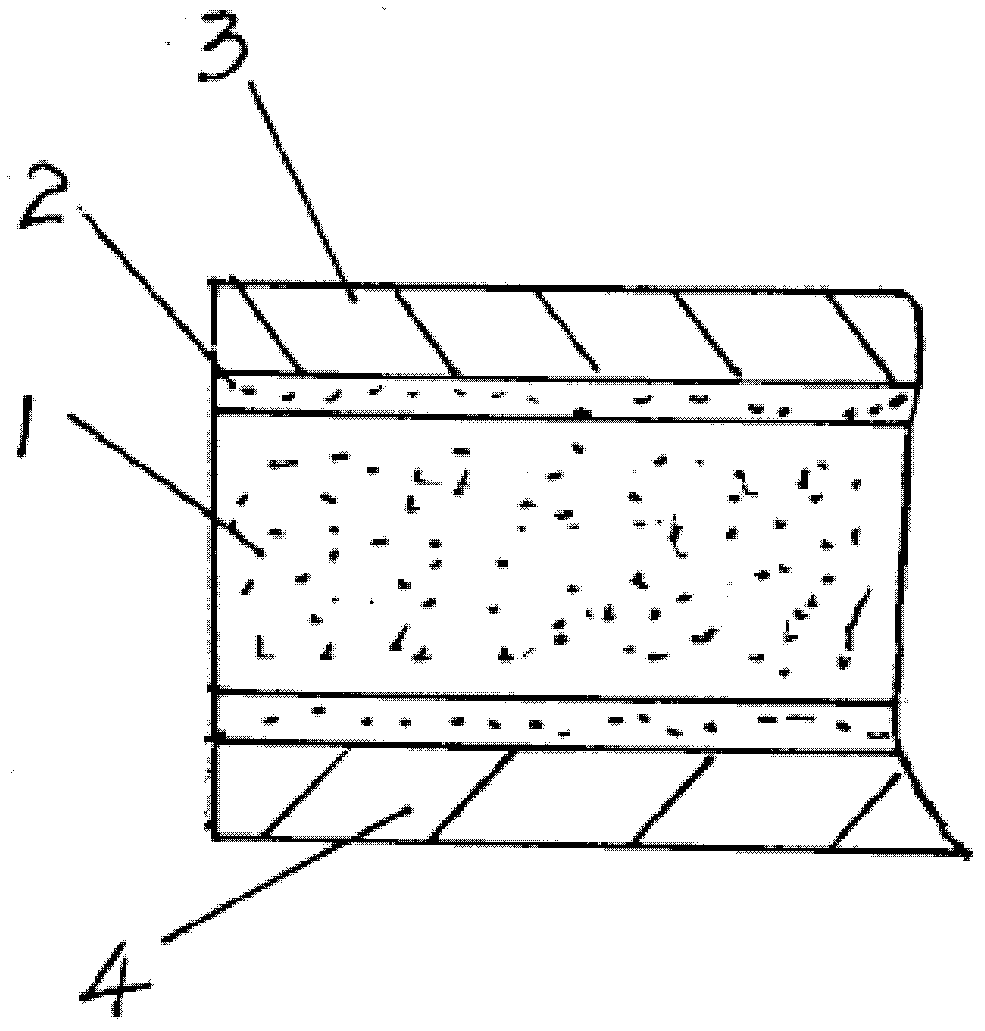

Image

Examples

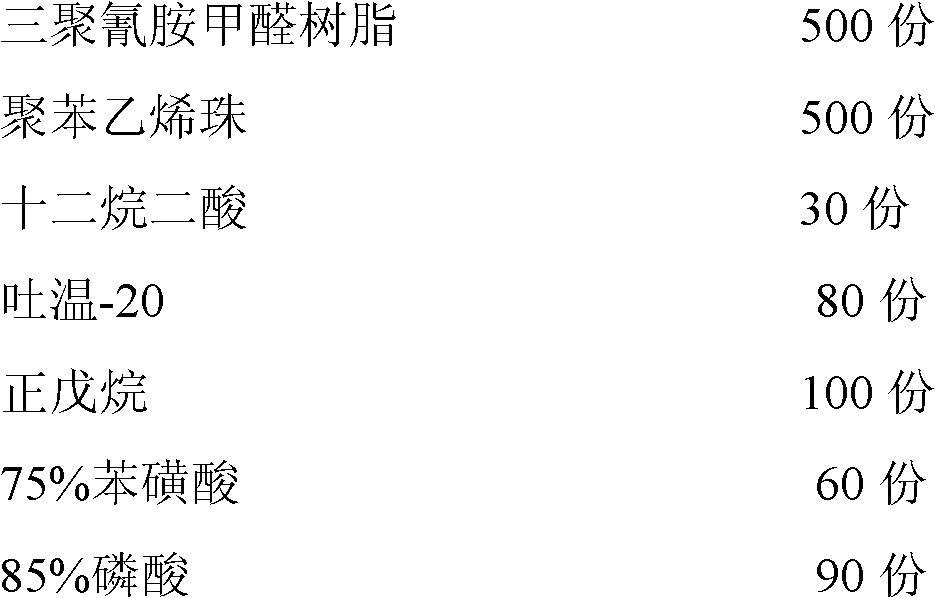

Embodiment 1

[0042]

[0043] Directly mix 60 parts of 75% benzenesulfonic acid and 90 parts of 85% phosphoric acid (liquid) evenly for later use.

[0044] In a beaker, mix and stir all the above ingredients except the acid premix for 5 minutes, preheat for 6 minutes to make the temperature of the mixture 30°C, then add the acid premix, and stir all the mixture manually for 1 minute, pour the mixture Put it into the pre-heated mold at 110°C for foaming and curing for 2 hours, and the polymer composite foam material is very light, with a density of only 25kg / m 3 , the foam opening rate still reaches more than 90%, which can maintain a good sound-absorbing effect. According to the GBJ 47-83 reverberation chamber method sound absorption coefficient measurement specification, the sound absorption coefficient of the composite foam for sound waves with a frequency greater than 1kHz is 0.62. Many evenly distributed expanded polystyrene beads can be clearly found on the surface of the foam, wit...

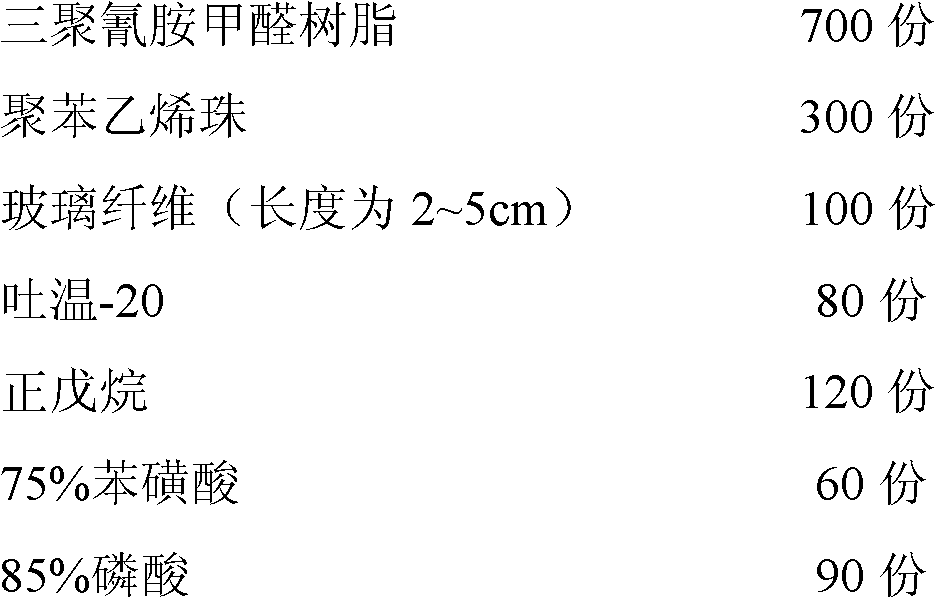

Embodiment 2

[0049]

[0050] Directly mix 60 parts of 75% benzenesulfonic acid and 90 parts of 85% phosphoric acid (liquid) evenly for later use.

[0051] In a beaker, mix and stir all the above ingredients except the acid premix for 6 minutes, preheat for 7 minutes to make the mixture temperature 30°C, then add the acid premix, and stir all the mixture manually for 1 minute, pour the mixture Put it into the pre-heated mold at 110°C for foaming and solidification for 2 hours, and the density of the prepared polymer composite foam material is 127kg / m 3 , the foam opening rate still reaches more than 90%, which can maintain a good sound-absorbing effect. According to the GBJ 47-83 reverberation chamber method sound absorption coefficient measurement specification, the sound absorption coefficient of the composite foam for sound waves with a frequency greater than 1kHz is 0.81. From the surface of the foam, many evenly distributed expanded polystyrene beads can be clearly found, with a di...

Embodiment 3

[0055]

[0056] Directly mix 60 parts of 75% benzenesulfonic acid and 90 parts of 85% phosphoric acid (liquid) evenly for later use.

[0057] In a beaker, mix and stir all the above ingredients except the acid premix for 4 minutes, preheat for 5 minutes to make the temperature of the mixture 30°C, then add the acid premix, and stir all the mixture vigorously by hand for 1 minute, pour the mixture Put it into the pre-heated mold at 110°C for foaming and curing for 2.5 hours, and the density of the prepared polymer composite foam material is 10kg / m 3 , the foam opening rate still reaches more than 90%, which can maintain a good sound-absorbing effect. According to the GBJ 47-83 reverberation chamber method sound absorption coefficient measurement specification, the sound absorption coefficient of composite foam for sound waves with frequencies greater than 1kHz is 0.94. Many evenly distributed expanded polystyrene beads can be clearly found on the surface of the foam, with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com