Resonance sound-absorbing structure for sheet

A resonant sound-absorbing, thin-plate technology, applied in the direction of sound-generating devices, instruments, etc., can solve the problems of increasing the weight of sound-absorbing structures, great influence of damping effect, and low sound-absorbing coefficient, and achieve light weight, small installation space, and improved absorption The effect of sound coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

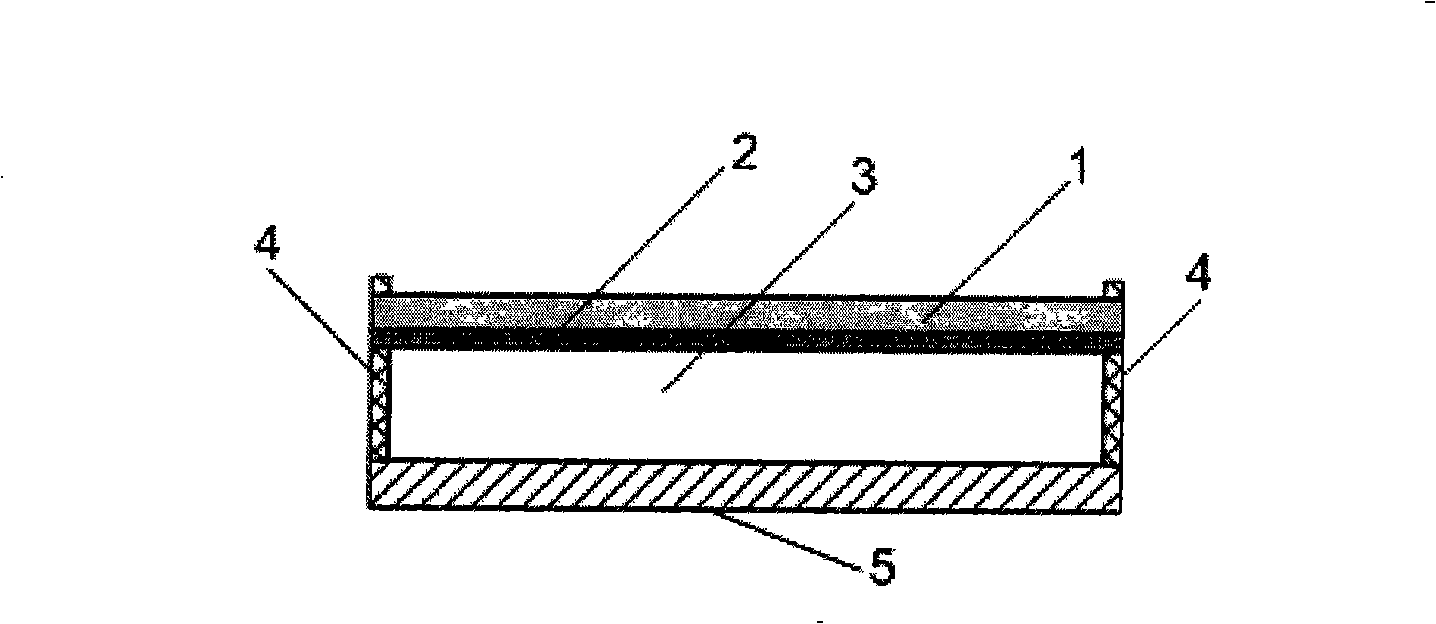

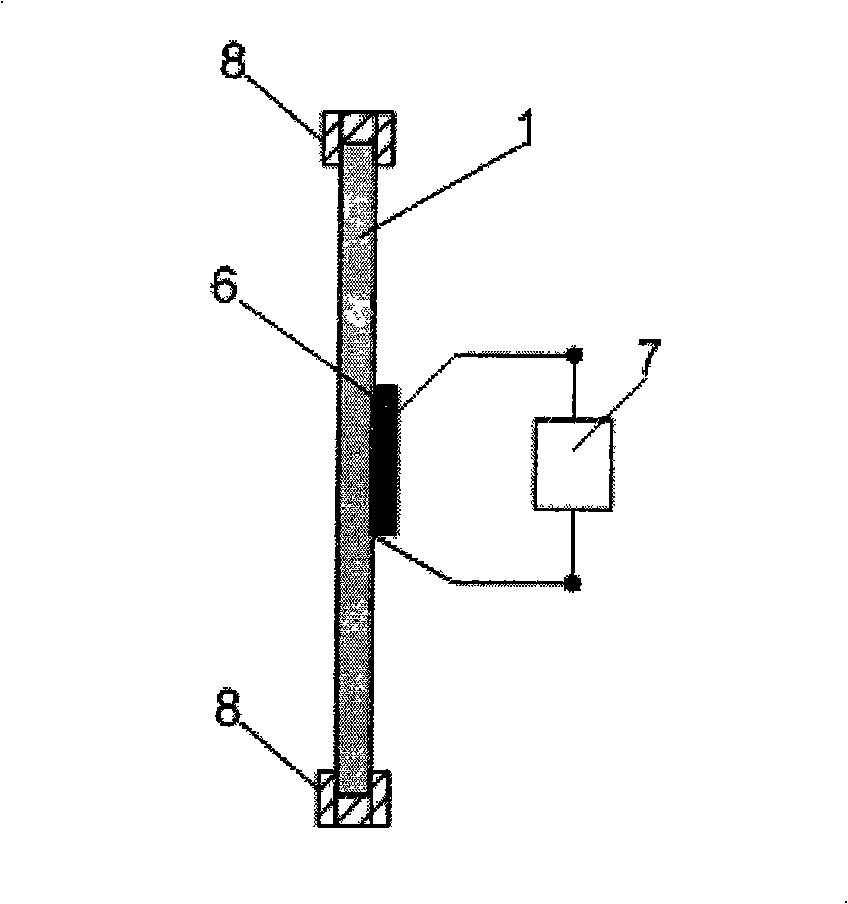

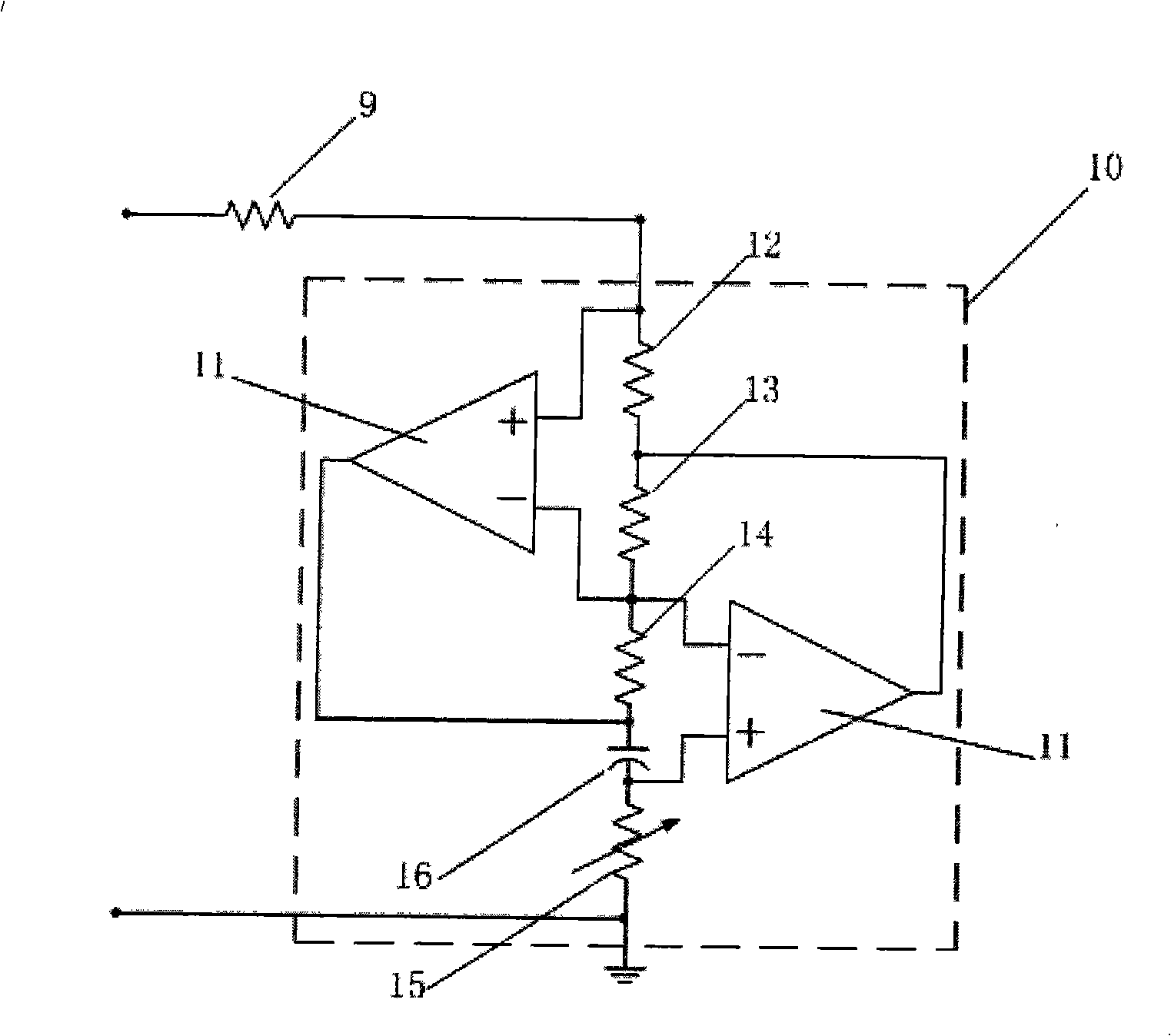

[0023] This embodiment is a thin-plate sound-absorbing structure applied to low frequencies. figure 2 Shown is the structural representation of this embodiment, it and figure 1 The main difference of the thin-plate resonant sound-absorbing structure shown is that the constrained damping layer 2 is replaced by a piezoelectric ceramic sheet 6 . The advantage is that the equivalent damping coefficient of the piezoelectric ceramic sheet can be adjusted through the parameters of the shunt circuit, so that the sound absorption coefficient of the metal plate can be controlled, and it can be greatly improved near the resonance frequency. Moreover, the piezoelectric ceramic sheet is lighter than the constrained damping layer, and its damping characteristics are not affected by environmental factors such as temperature. In addition, the thin-plate resonance sound-absorbing structure of the present invention does not need to close the cavity, which greatly reduces the installation spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com