Special sound absorbing plate for polymerized-sand tunnel and preparation method thereof

A technology of sound-absorbing panels and aggregated sand, applied in noise-absorbing devices, buildings, etc., can solve problems such as large impact force, and achieve the effects of large sound absorption coefficient, low cost, and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The special sound-absorbing panel for aggregated sand tunnels of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention but not to limit the present invention.

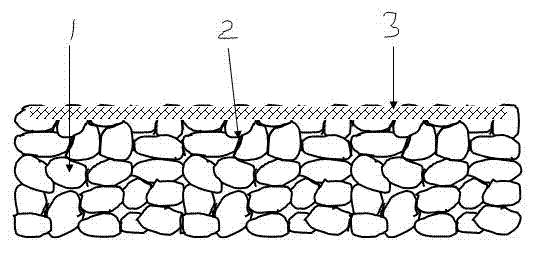

[0022] The special sound-absorbing panel for aggregated sand tunnels of the present invention is formed by polymerizing and pressing three parts: sand grains 1, silicon-based polymer 2, and steel mesh 3.

[0023] As the grit, natural silica grit was used. Silicon-based polymers include: organohydroxy silicone 45%, organomethyl silicone 15%, methyl silane 3%, silica fine powder 6%, calcium carbonate 8%, aminosilane 0.4%, dibutyl dibutyl Aluminum laurate 0.04%, polyether (molecular weight 5000) 6%, isocyanate 5%, hydroxyl resin 4%, tributyl phosphate 7%.

[0024] The principle of polymerization reaction is: the molecular chain of the polymer has an asymmetric structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com