Low-density underwater sound absorbing plate and preparation method thereof

A low-density, plate-based technology, applied in chemical instruments and methods, sound-generating devices, synthetic resin layered products, etc., can solve the problems of large overall weight and limited use range of sandwich structures, and meet the requirements of structural load-bearing strength and stiffness, Improve the sound absorption effect and reduce the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Upper component: matrix resin 200kg (of which: epoxy resin 6350 is 100kg, polyurethane modified epoxy resin is 100kg), filler 45kg (of which: hollow glass microsphere QH-700 is 15kg, hollow glass microsphere K-600 is 5kg, hollow glass microsphere K-180 is 5kg, muscovite is 20kg), curing agent 45kg (among them: 593 is 30kg, polyetheramine D2000 is 15kg), auxiliary agent 10kg (coupling agent KH550);

[0022] Lower component: matrix resin 450kg (of which: polyurethane is 200kg, polyurethane modified epoxy resin is 250kg), filler 115kg (of which: hollow glass microsphere QH-700 is 30kg, hollow glass microsphere K-600 is 20kg, hollow Glass microsphere K-800 is 20kg, hollow glass microsphere K-100 is 20kg, muscovite is 20kg, chopped fiber is 5kg), curing agent is 125kg (of which: 593 is 65kg, polyetheramine D2000 is 20kg, polyether Amine T5000 is 30kg, DMP-30 is 10kg), auxiliary agent is 10kg (coupling agent KH550). The aforementioned chopped fibers are cut from glass fiber ...

Embodiment 2

[0026] Upper component: matrix resin 170kg (polyurethane modified epoxy resin), filler 35kg (including: hollow glass microsphere QH-700 is 10kg, hollow glass microsphere K-180 is 15kg, muscovite is 10kg), curing agent 40kg (593), auxiliary agent 5kg (coupling agent KH550);

[0027] Lower layer components: matrix resin 450kg (epoxy resin 6350), filler 140kg (of which: hollow glass microsphere QH-700 is 60kg, hollow glass microsphere K-600 is 10kg, hollow glass microsphere K-180 is 40kg, Baiyun Motherboard is 30kg), curing agent 140kg (of which: 593 is 100kg, polyetheramine T5000 is 40kg), auxiliary agent 20kg (coupling agent KH550).

[0028] Weigh the base resin after dehydration according to the above ratio, add dry filler after surface treatment with coupling agent after preheating, then add auxiliary agent and curing agent, and use electric stirring and other dispersion techniques to make the filler in the base resin Fully disperse in the medium, trigger cross-linking and c...

Embodiment 3

[0030] Upper component: matrix resin 200kg (of which: epoxy resin 6350 is 100kg, polyurethane modified epoxy resin is 100kg), filler 45kg (of which: hollow glass microsphere QH-700 is 20kg, hollow glass microsphere K-180 is 5kg, hollow glass microsphere K-100 is 20kg), curing agent 45kg (of which: 593 is 30kg, polyetheramine T5000 is 15kg), auxiliary agent 10kg (coupling agent KH550);

[0031] Lower component: matrix resin 400kg (polyurethane modified epoxy resin), filler 150kg (of which: hollow glass microsphere K-600 is 30kg, hollow glass microsphere K-180 is 30kg, hollow glass microsphere K-800 is 50kg , muscovite is 40kg), curing agent 120kg (of which: 593 is 80kg, polyetheramine D2000 is 30kg, DMP-30 is 10kg), auxiliary agent 30kg (of which: coupling agent KH550 is 10kg, diluent 501 is 10kg, Dispersant BYK903 is 10kg).

[0032] Weigh the base resin after dehydration according to the above ratio, add dry filler after surface treatment with coupling agent after preheating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

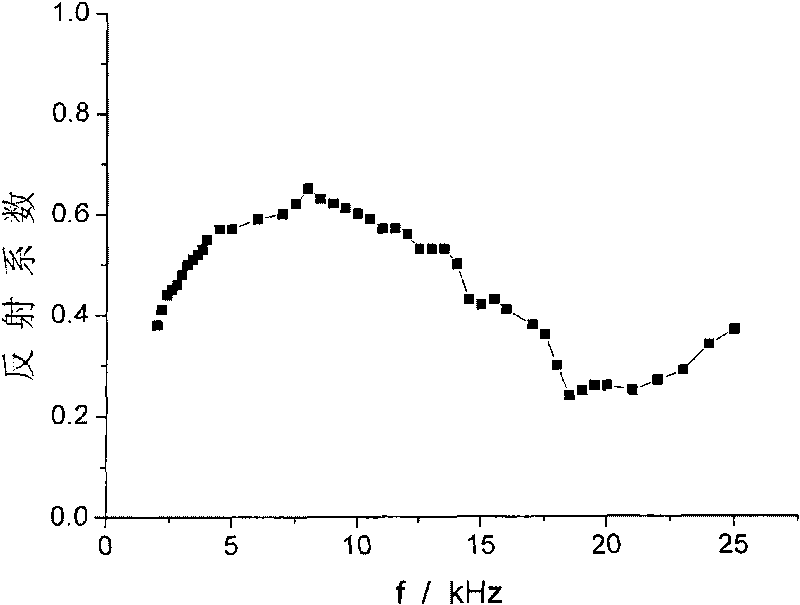

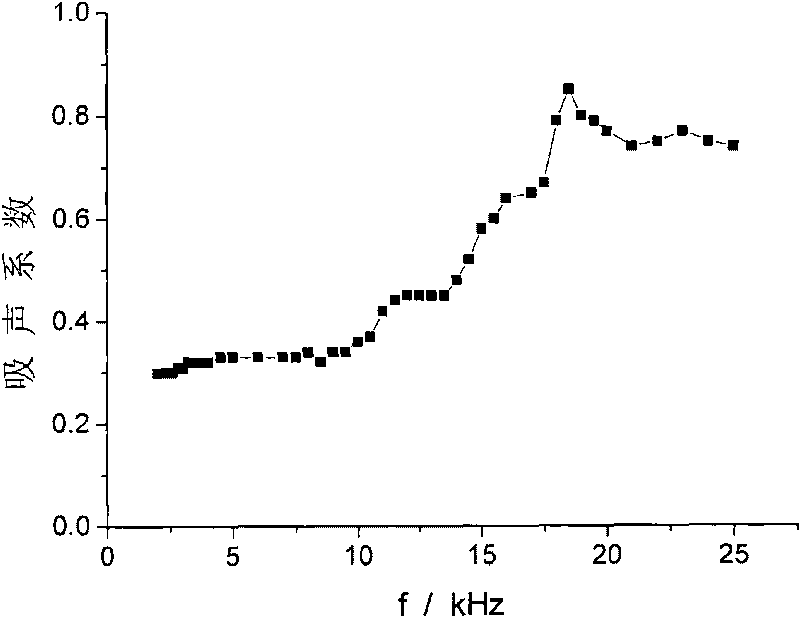

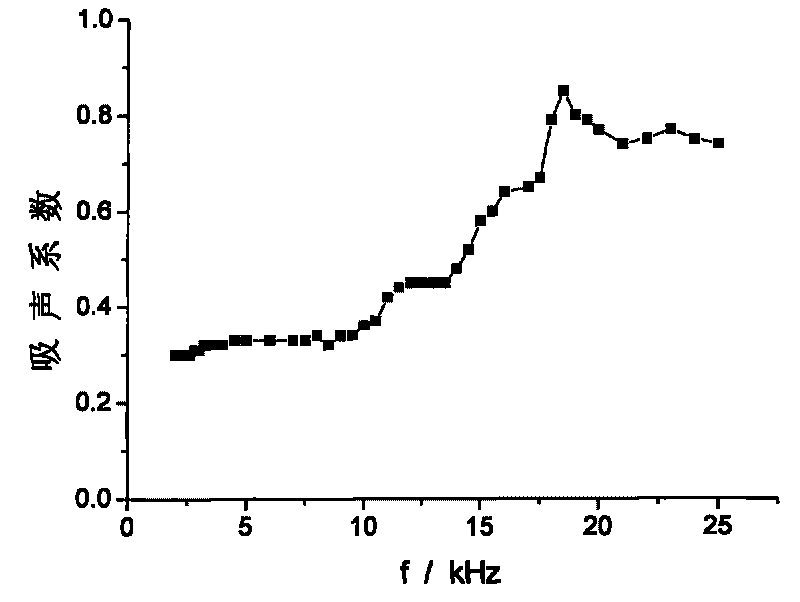

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com