Cement reinforced composite heat preservation brickwork and its production method

A technology for enhancing composite and cement, applied in the direction of heat preservation, manufacturing tools, building components, etc., can solve the problems of ineffective utilization of straw stalks, inconvenient transportation and use, damage to land resources, etc. The effect of light weight and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

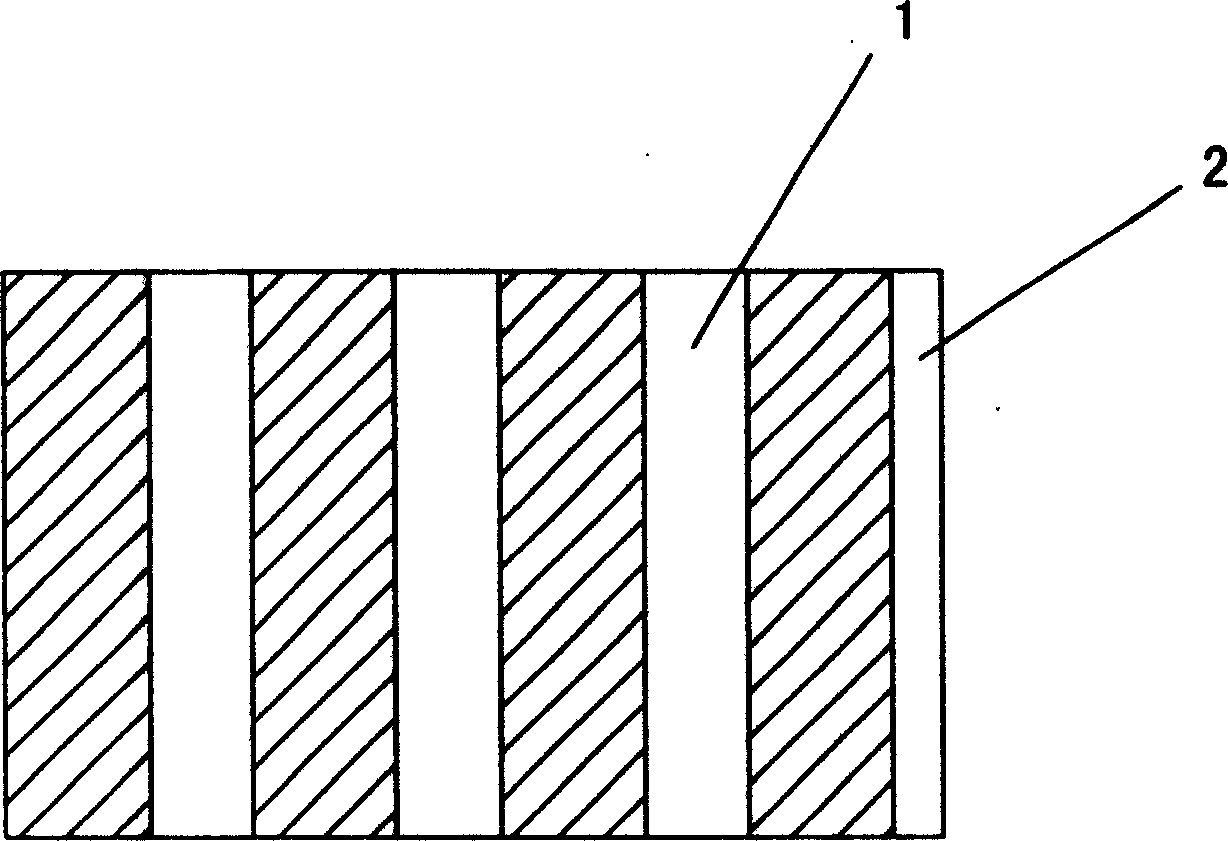

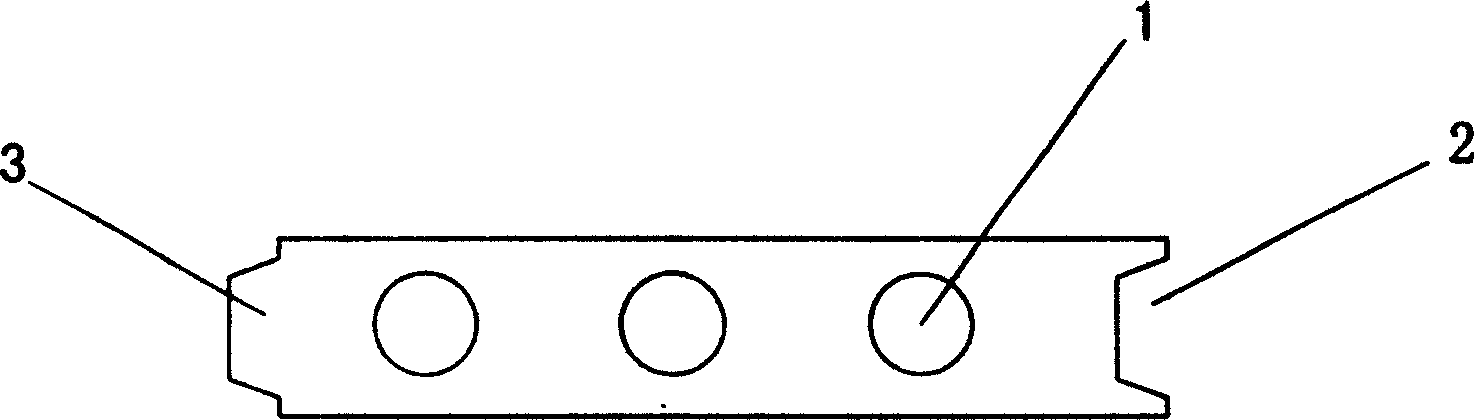

Embodiment 1

[0032] Take 76 kg of dry rice straw and cotton stalk mixture, crush it with a pulverizer until it reaches a size of 60 mesh, then put in 23 kg of low-alkali sulfoaluminate cement 325#, mix and stir, then take 0.5 kg of 108 glue, press 108 glue: water = 1:6.5 ratio, add water, mix and pour, stir evenly into granules, inject the evenly stirred ingredients into the mold, press and form under 114MPa pressure, its shape is cuboid, length is 600mm, width is 400mm, thickness is 120mm, an inlay groove 2 is provided on one side of the brick body, and an inlay block 3 configured with the inlay groove is provided on the other side of the brick. Three through holes 1 are opened in the middle of the brick body along the width direction, and a surface is sprayed with a One layer of white paint, and then dried naturally at room temperature for 7 days to make cement-reinforced composite thermal insulation bricklaying, and the inspection data of the finished product are shown in the attached ta...

Embodiment 2

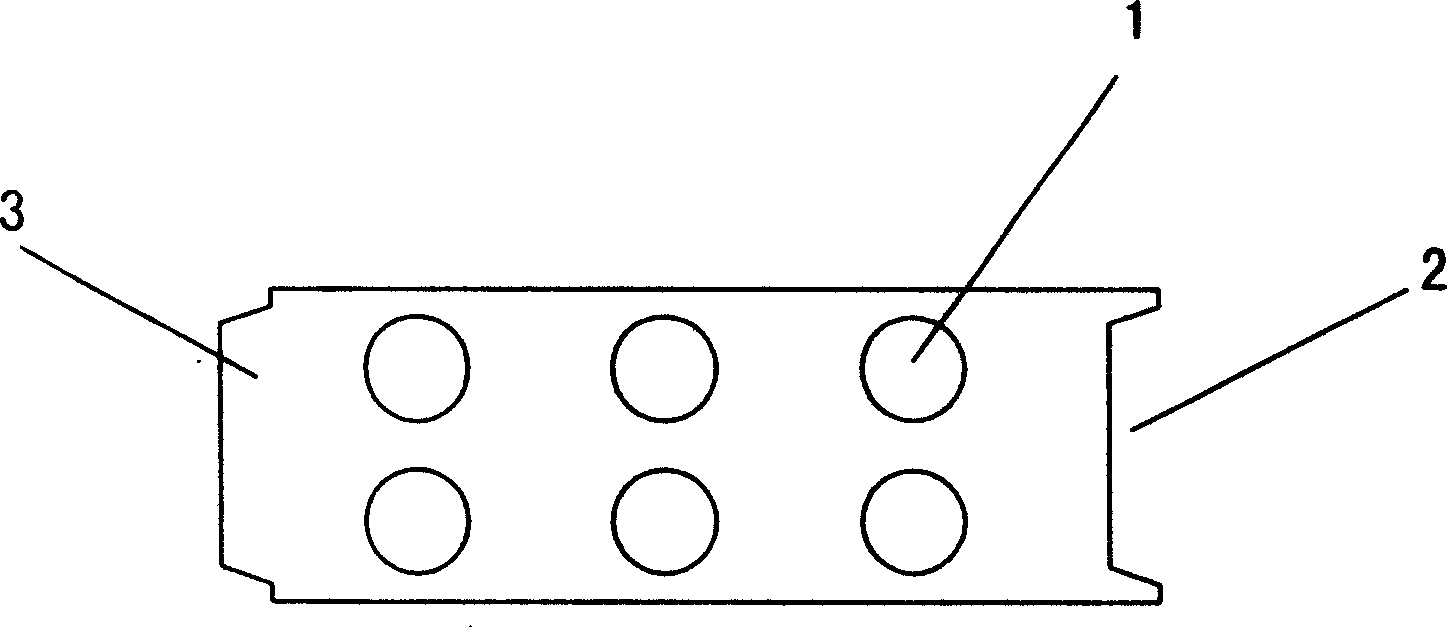

[0035] Take 81 kg of dry rice straw, corn stalks and bean stalks, pulverize them with a pulverizer until they reach a size of 60 mesh, then put 18 kg of low-alkali sulfoaluminate cement 425#, mix and stir, then take 0.5 kg of 108 glue, press 108 glue: water = 1: 6.5, add water, mix and pour, stir evenly into granules, pour the evenly stirred ingredients into the mold, press and form under 114MPa pressure, its shape is rectangular parallelepiped, 600mm long and 600mm wide 400mm, thickness 240mm, an inlay groove 2 is provided on one side of the brick body, and an inlay block 3 configured with the inlay groove is arranged on the other side of the brick body. Two rows of six through holes 1 are opened in the middle of the brick body along the width direction. A layer of blue paint was sprayed on the surface, and then dried naturally at room temperature for 7 days to obtain a cement-reinforced composite thermal insulation brick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com