Fire-retardant black iron oxide pigment

A technology of iron oxide black and pigment, which is applied in the field of flame-retardant iron oxide black pigment and its preparation, which can solve the problems of insufficient brightness, easy agglomeration, and difficulty in uniform dispersion of the medium, and achieve uniform dispersion, strong hiding power, and good anti-sedimentation The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

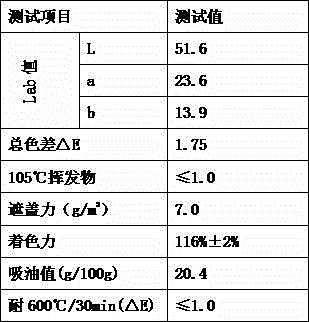

Image

Examples

Embodiment

[0011] The pigment in this example is made of the following raw materials in parts by weight: iron oxide black 300, sodium montmorillonite 8, silane coupling agent KH-550 1, antimony trioxide 5, pyrophyllite powder 6, calcium stearate 1, Polyethylene wax 4, sodium dodecyl sulfonate 1, fly ash 12, additive 5.

[0012] The auxiliary agent is made of the following raw materials in parts by weight: aluminum hydroxide 4, aminopropyltriethoxysilane 1, tamarind gum 1, expanded perlite 12, graphene 8, pentaerythritol 2, magnesium oxide 3, Sodium dihydrogen phosphate 2, sodium metasilicate 1; the preparation method is to mix tamarind gum and sodium metasilicate first, add an appropriate amount of water, stir until the mixture is completely dissolved and dispersed, then add other remaining ingredients and stir thoroughly After uniformity, dry at a constant temperature of 50-60°C for 4 hours, and grind the mixture into a 300-mesh powder after drying.

[0013] Described a kind of flame-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com