Insulating fireproof radiation-resistant shielded cable material and preparation method thereof

A shielded cable and anti-radiation technology, which is applied in the direction of insulators, rubber insulators, organic insulators, etc., can solve the problems of high halogen content, environmental pollution, and failure to meet environmental protection requirements, and achieve simple manufacturing process, low raw material prices, and product costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

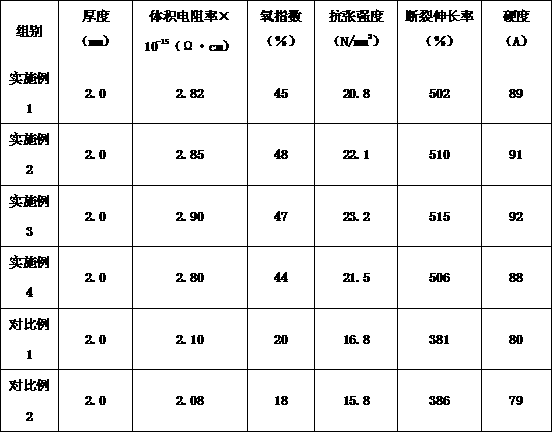

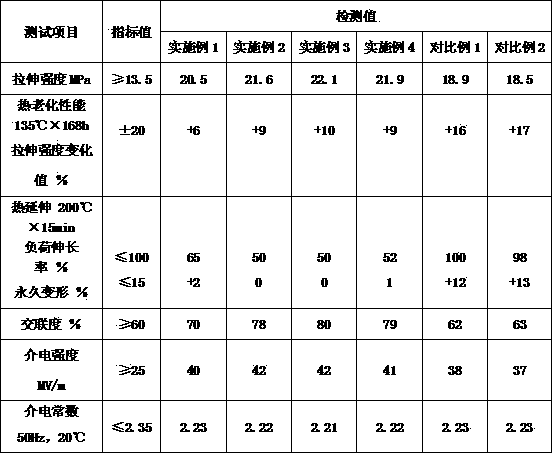

Examples

Embodiment 1

[0021] Insulated fire-resistant and radiation-resistant shielded cable material is prepared from the following raw materials in parts by weight: 50 parts of ethylene-butadiene rubber, 55 parts of ethylene-vinyl acetate copolymer, 30 parts of polyvinyl chloride, 35 parts of phenolic resin, polydimethylsiloxane 25 parts of oxane, 25 parts of glass fiber, 20 parts of dioctyl sebacate, 20 parts of dicumyl peroxide, 30 parts of silane coupling agent, 12 parts of anti-aging agent DDA, 15 parts of tribasic lead sulfate, flame retardant 30 parts of agent, 16 parts of 2-thiol benzimidazole.

[0022] In the ethylene-vinyl acetate copolymer, the mass percentage of ethylene is 56%, and the mass percentage of vinyl acetate is 44%.

[0023] The flame retardant is a mixture of aluminum oxide and silicon nitride, the ratio of which is 1:0.7 in parts by weight, and the particle diameters of the aluminum oxide and silicon nitride are both less than 10 μm.

Embodiment 2

[0025] Insulated fire-resistant and radiation-resistant shielded cable material is prepared from the following raw materials in parts by weight: 54 parts of ethylene-butadiene rubber, 51 parts of ethylene-vinyl acetate copolymer, 34 parts of polyvinyl chloride, 31 parts of phenolic resin, polydimethylsiloxane 28 parts of oxane, 21 parts of glass fiber, 24 parts of dioctyl adipate, 18 parts of dicumyl peroxide, 34 parts of silane coupling agent, 11 parts of anti-aging agent DDA, 17 parts of tribasic lead sulfate, flame retardant 28 parts of agent, 17 parts of 2-thiol benzimidazole.

[0026] In the ethylene-vinyl acetate copolymer, the mass percentage of ethylene is 62%, and the mass percentage of vinyl acetate is 38%.

[0027] The flame retardant is a mixture of aluminum oxide and silicon nitride, the ratio of which is 1:0.78 by weight, and the particle diameters of the aluminum oxide and silicon nitride are both less than 10 μm.

Embodiment 3

[0029] Insulated, fire-resistant and radiation-resistant shielded cable material is prepared from the following raw materials in parts by weight: 57 parts of ethylene-butadiene rubber, 48 parts of ethylene-vinyl acetate copolymer, 37 parts of polyvinyl chloride, 27 parts of phenolic resin, polydimethylsiloxane 32 parts of oxane, 17 parts of glass fiber, 28 parts of dioctyl phthalate, 17 parts of dicumyl peroxide, 38 parts of trimethylolpropane triacrylate, 11 parts of antioxidant DDA, dibutyltin dilaurate 19 parts, 26 parts of flame retardant, 101018 parts of antioxidant.

[0030] In the ethylene-vinyl acetate copolymer, the mass percentage of ethylene is 66%, and the mass percentage of vinyl acetate is 34%.

[0031] The flame retardant is a mixture of aluminum oxide and silicon nitride, the ratio of which is 1:0.84 by weight, and the particle diameters of the aluminum oxide and silicon nitride are both less than 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com