Novel composite thermal insulation building block and producing method thereof

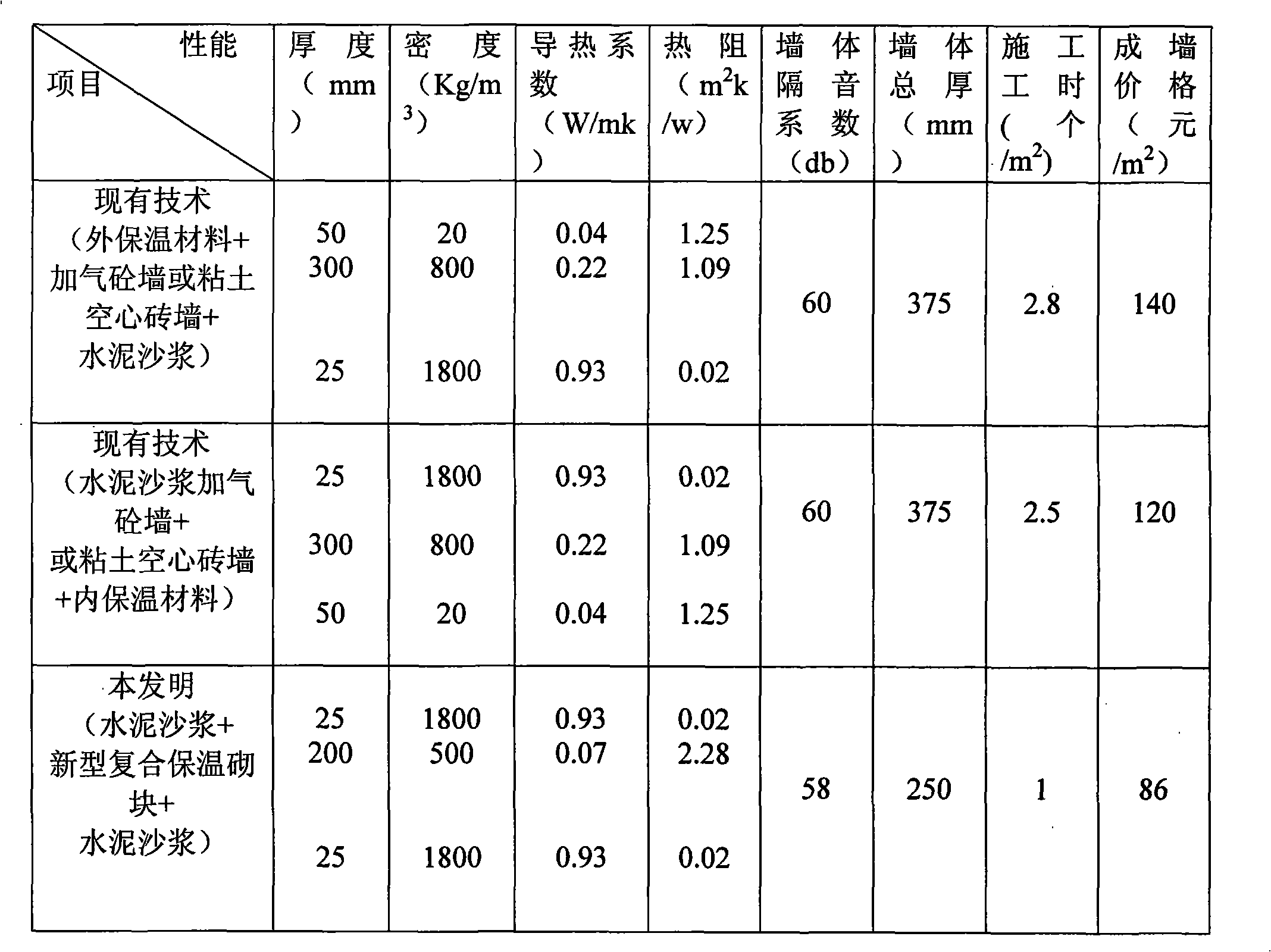

A composite thermal insulation and building block technology, applied in the field of building materials, can solve the problems of slow construction speed, poor thermal insulation effect, high construction cost, etc., and achieve the effects of fast construction, firm bonding, and increased use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

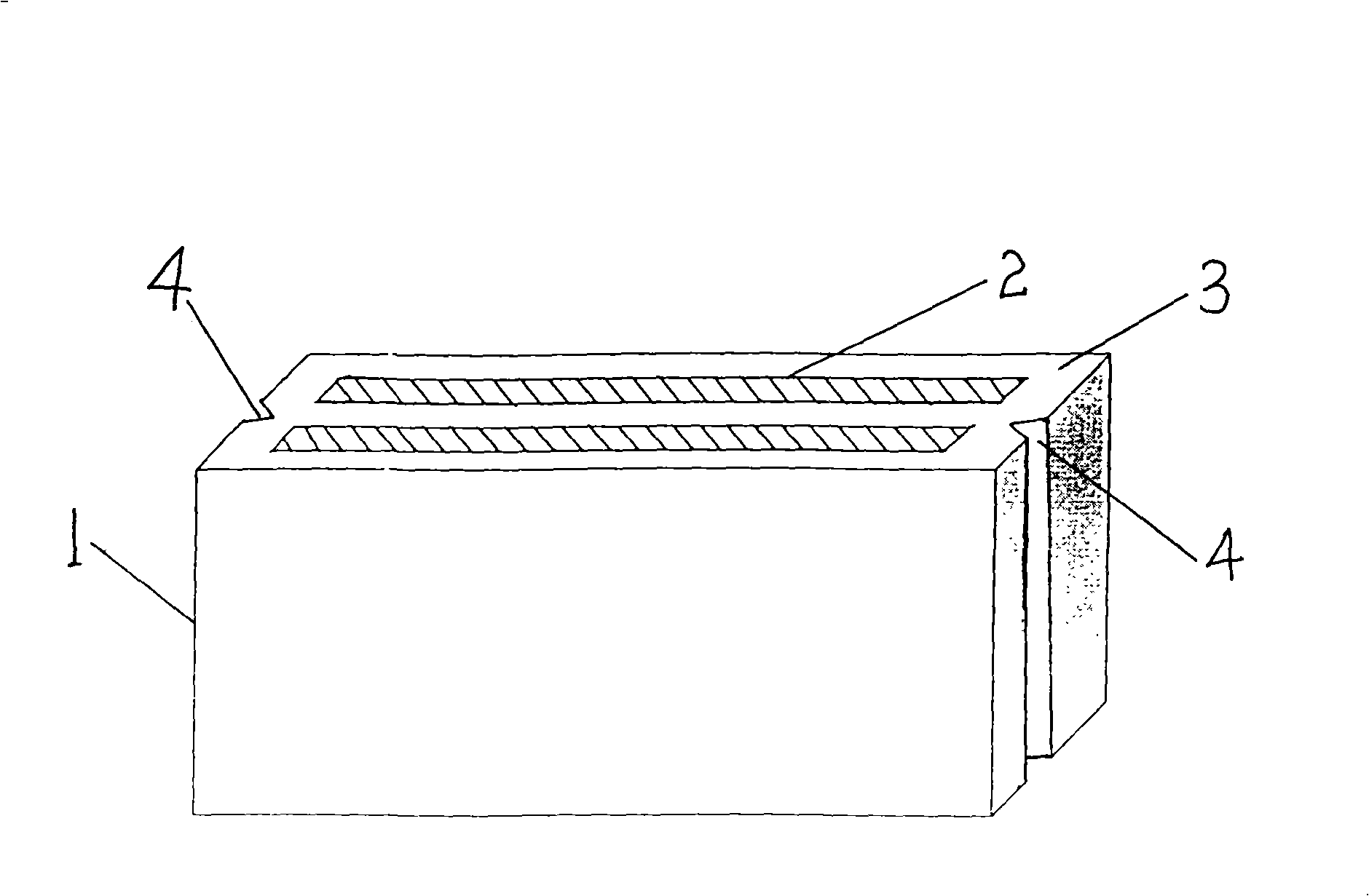

[0018] Embodiment 1: The composite thermal insulation block of the present invention has a block body 1, and the block body 1 is composed of a thermal insulation layer 2 and a reinforcement layer 3; the thermal insulation layer 2 is made of a polystyrene board, At least one layer is provided; a reinforced layer 3 made of cement mortar mixture is injected on the outside of the thermal insulation layer 2; at least one The ash slot 4 is used to strengthen the bond between two block bodies.

[0019] The reinforcement layer is made of cement, sand, coal ash, gypsum powder, glass fiber filaments, and water reducing agent in a ratio of 100:50:20:10:0.2:1. Add water and stir in a mixer to form a thin paste mixture. of.

[0020] The production method of composite thermal insulation block of the present invention:

[0021] Divide the polystyrene board into proper size according to the size of the mold, and fix it in the mold; then mix cement, sand, coal ash, gypsum powder, glass fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com