Paperboard processing device

A technology for processing equipment and cardboard, applied in the direction of metal processing, cardboard items, etc., can solve the problems of non-compliance with the grain direction, reduce the flatness of cutting, and not easy to cut, so as to achieve smooth cuts, avoid equipment jamming, and improve The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

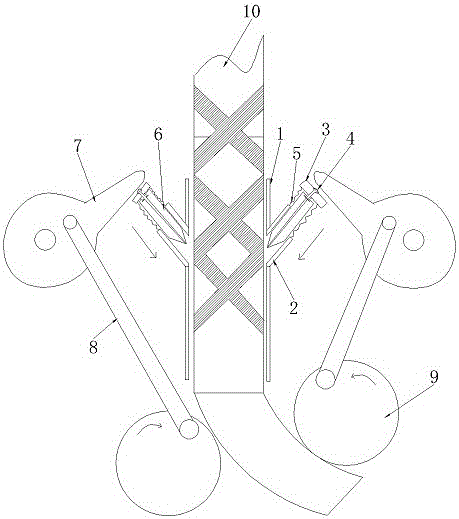

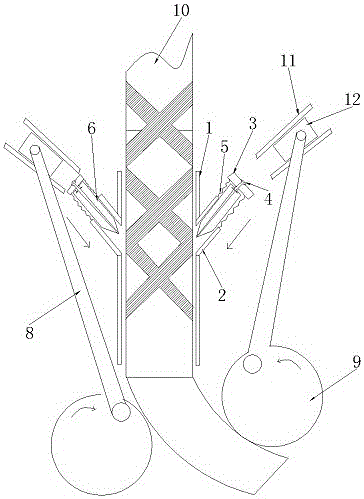

[0022] Embodiment 1 is basically as attached figure 1 Shown: a cardboard processing equipment, including a material introduction chamber 1 for guiding the cardboard to the cutting position; a through hole is symmetrically opened in the middle of the material introduction chamber 1, and a cutting chamber 2 is fixedly installed on the through hole, and the inclination angle of the cutting chamber 2 is the same as The honeycomb pattern of the paper core is the same; the cutting cavity 2 is slidingly connected with 6, and the top of the blade 6 is provided with a limit block 3, and the limit block 3 is connected with the upper edge of the cutting cavity 2 by a spring 5. The part of the stop block 3 that is knocked by the cam 7 is provided with a concave cavity, and the surface of the concave cavity is provided with a layer of rubber film 4; Both sides of the outlet of the material introduction cavity 1 are provided with round rollers 9 that can drive the discharge. The rotating sp...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that the beating part is a guide rail 11 installed above the limit block, and a slider 12 slidably connected to the guide rail 11 and eccentrically hinged with the round roller; the length of the guide rail is greater than that of the slider Upper limit position when driven. The round roller and the slider constitute a slider crank mechanism, which changes the periodic rotation of the round roller into the reciprocating motion of the slider 12, thereby realizing the beating of the limit block 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com