Functional modification processing method and product for knitted animal down product

A processing method and functional technology, applied in textiles and papermaking, ultrasonic/sonic fiber processing, fiber processing, etc., can solve the problems of poor skeleton fullness, poor resilience, easy fluff, etc., to achieve easy to master, The skeleton is plump and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

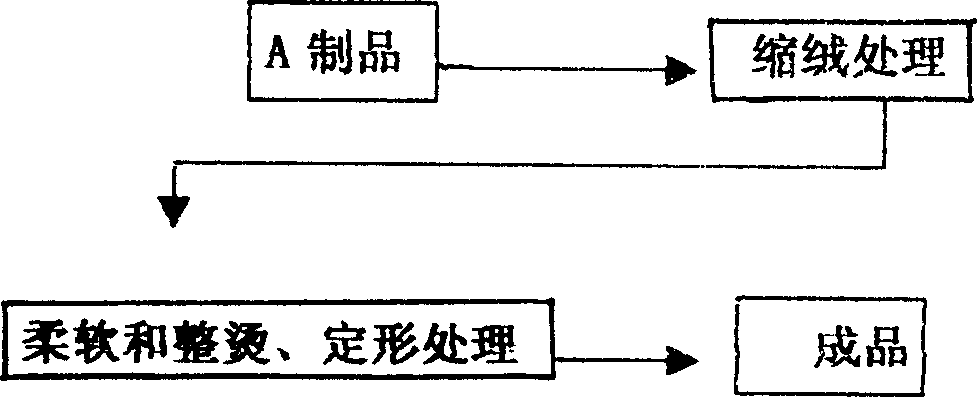

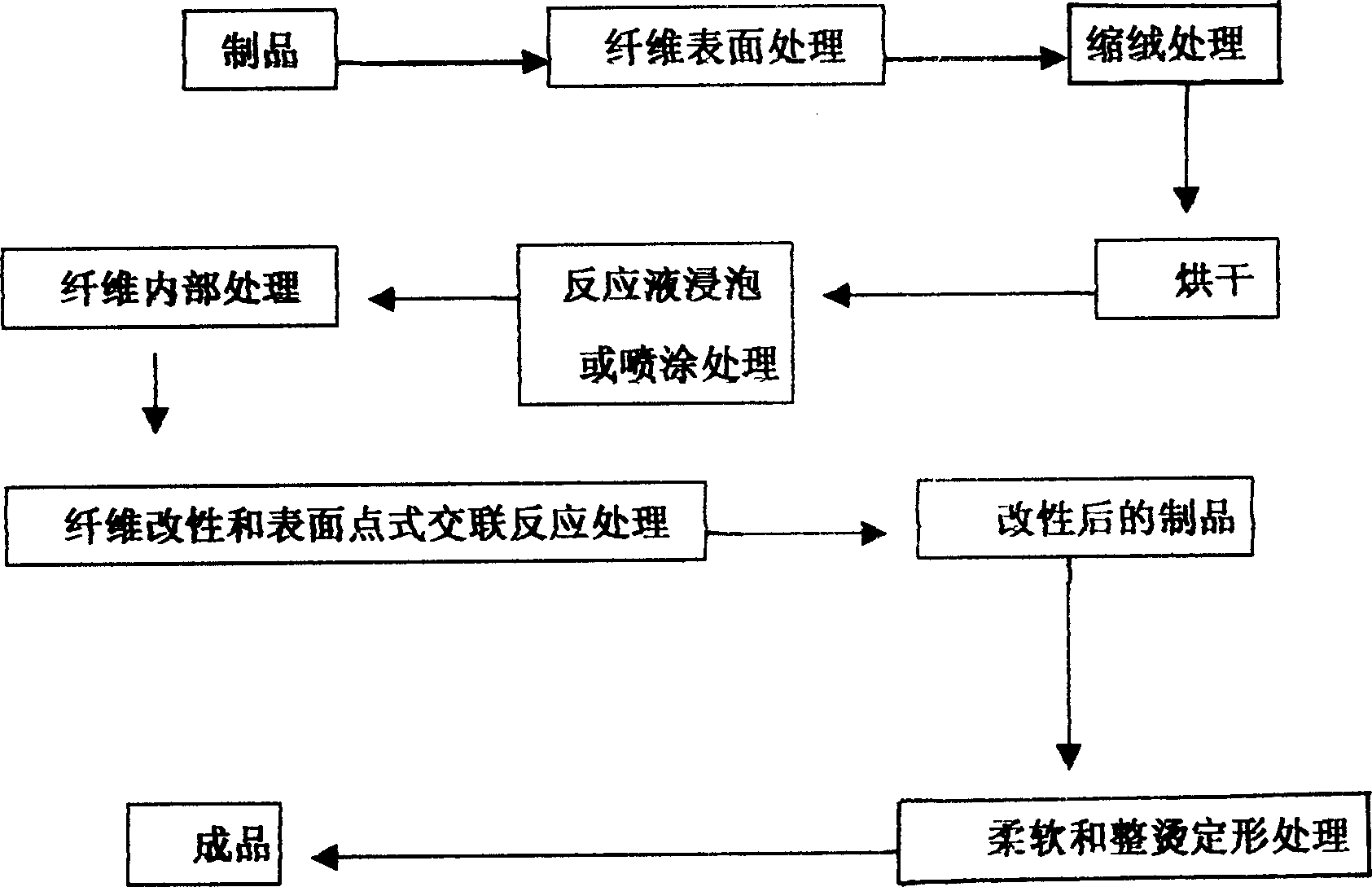

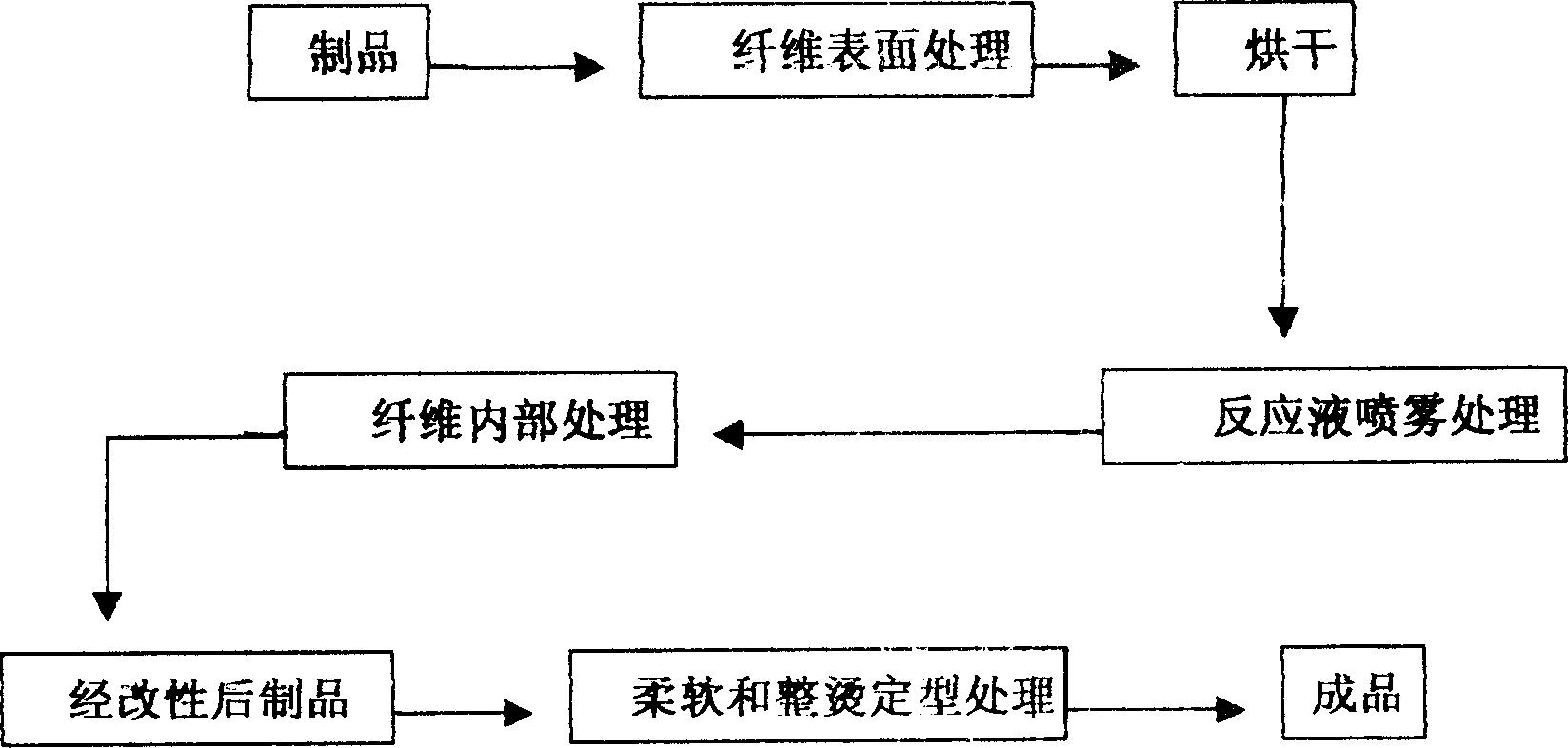

Method used

Image

Examples

Embodiment Construction

[0029] A. Take 1 kg of knitted pure cashmere sweater and put it into 10 kg of soft water, 10 g of acetic acid, 100 g of PROTOIAN368, and 10 g of ceramic powder with an average particle size of 1 μm. The ultrasonic frequency is 28 kHz, and the power is 1 kW. Soak for 10 minutes in a container tank that emits ultrasonic waves, and the temperature is between 30-35°C. Carry out rinsing, dehydration, spin-dry afterwards, make the liquid content rate be at 35%.

[0030] B. Take out the cashmere sweater treated by A and put it in the shrinking machine, and add the shrinking agent and soft water for shrinking treatment according to the routine, so that the length of the shrinkage is about 1-3mm.

[0031] C. Spin and dry to keep the liquid content at 12%.

[0032] D, soak the cashmere sweater that has been dried and dried in a container with a ratio of 1:10 (dry weight cashmere sweater 1, mixed liquid 10) prepared by 94% soft water and 6% mspu (its main component is polyurethane) Li,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com