Active antibacterial and antiviral glove and preparation method thereof

An anti-virus and anti-viral agent technology, applied in the field of gloves, can solve the problems of not being able to effectively inhibit the growth and reproduction of bacteria, easy to breed bacteria, etc., and achieve durable antibacterial and antiviral properties, long-lasting antibacterial and antiviral effects, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

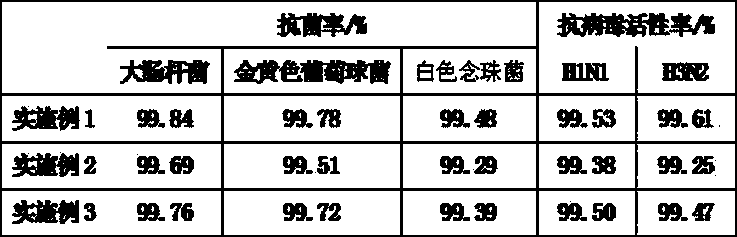

Examples

Embodiment 1

[0029] The first stage:

[0030] Slowly add 33 parts by weight of natural rubber latex to 50 parts by weight of nitrile rubber latex, stir and disperse evenly, heat up to 80°C and knead for 2 hours to prepare a rubber compound.

[0031] second stage:

[0032] In the sizing material of 83 parts by weight prepared in the first stage, under mechanical stirring, sequentially add 2 parts by weight of sodium hydroxide, 1 part by weight of sulfur powder, 3 parts by weight of nano silver, 1.2 parts by weight of diethyl diethyl Zinc thiocarbamate, 0.8 parts by weight of zinc di-n-butyldithiocarbamate, 1.2 parts by weight of titanium dioxide, 0.2 parts by weight of benzalkonium bromide, and 0.3 parts by weight of chitosan. After stirring evenly (pre-stirring for 30 minutes), heat up to 80°C and knead for 3 hours to prepare antibacterial and antiviral rubber latex.

[0033] The third stage:

[0034] Put the antibacterial and antiviral rubber latex prepared in the second stage into the...

Embodiment 2

[0037] The first stage:

[0038] Slowly add 30 parts by weight of acrylate latex and 30 parts by weight of polybutadiene latex to 30 parts by weight of nitrile rubber latex in sequence, stir and disperse evenly, raise the temperature to 65°C, and knead for 3 hours to obtain a rubber compound.

[0039] second stage:

[0040] In the sizing material of 90 parts by weight prepared in the first stage, under mechanical stirring, sequentially add 3 parts by weight of sodium hydroxide, 0.5 parts by weight of sulfur powder, 2 parts by weight of nano-silver, and 0.8 parts by weight of diethyl bismuth Zinc thiocarbamate, 0.5 parts by weight of zinc di-n-butyldithiocarbamate, 1 part by weight of titanium dioxide, 0.1 parts by weight of methylisothiazol-3-one, and 0.2 parts by weight of chitin. After stirring evenly (pre-stirring for 30 minutes), heat up to 65°C and knead for 4 hours to prepare antibacterial and antiviral rubber latex.

[0041] The third stage:

[0042] Put the antibact...

Embodiment 3

[0045] The first stage:

[0046] Slowly add 10 parts by weight of polyvinyl chloride latex, 20 parts by weight of styrene-butadiene latex, and 20 parts by weight of polybutadiene latex to 45 parts by weight of natural rubber latex. After stirring and dispersing evenly, heat up to 70°C and mix for 2.5 hours. , to prepare rubber.

[0047] second stage:

[0048] In the sizing material of 95 parts by weight prepared in the first stage, under mechanical stirring, sequentially add 1 part by weight of sodium hydroxide, 1.2 parts by weight of sulfur powder, 3.2 parts by weight of nano silver, 1 part by weight of diethyl diethyl Zinc thiocarbamate, 1 part by weight of zinc di-n-butyldithiocarbamate, 1.2 parts by weight of titanium dioxide, 0.3 parts by weight of polyhexamethyleneguanidine hydrochloride, and 0.3 parts by weight of castor oil. After stirring evenly (pre-stirring for 30 minutes), heat up to 70°C and knead for 3.5 hours to prepare antibacterial and antiviral rubber latex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com