Water-soluble near-infrared quantum dot, preparation method and application thereof

A quantum dot and near-infrared technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as poor stability, low quantum yield, and long time consumption, and achieve less surface defects, high quantum yield, and shortened time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

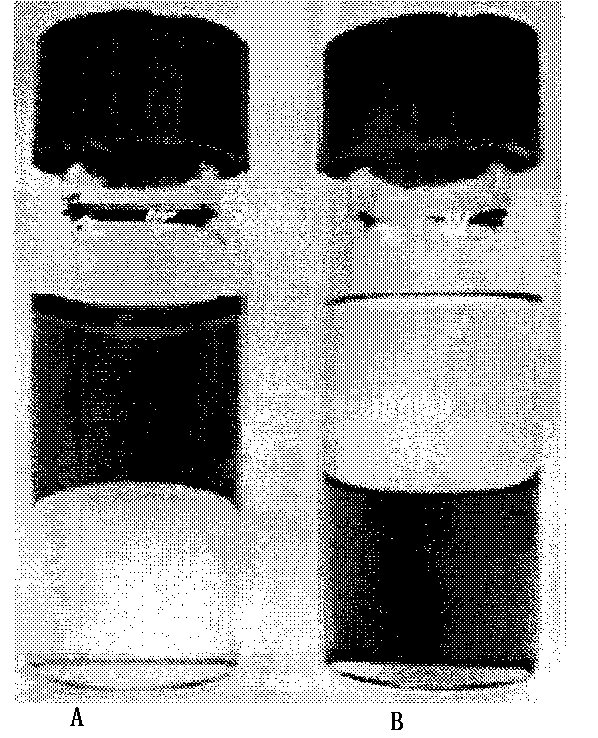

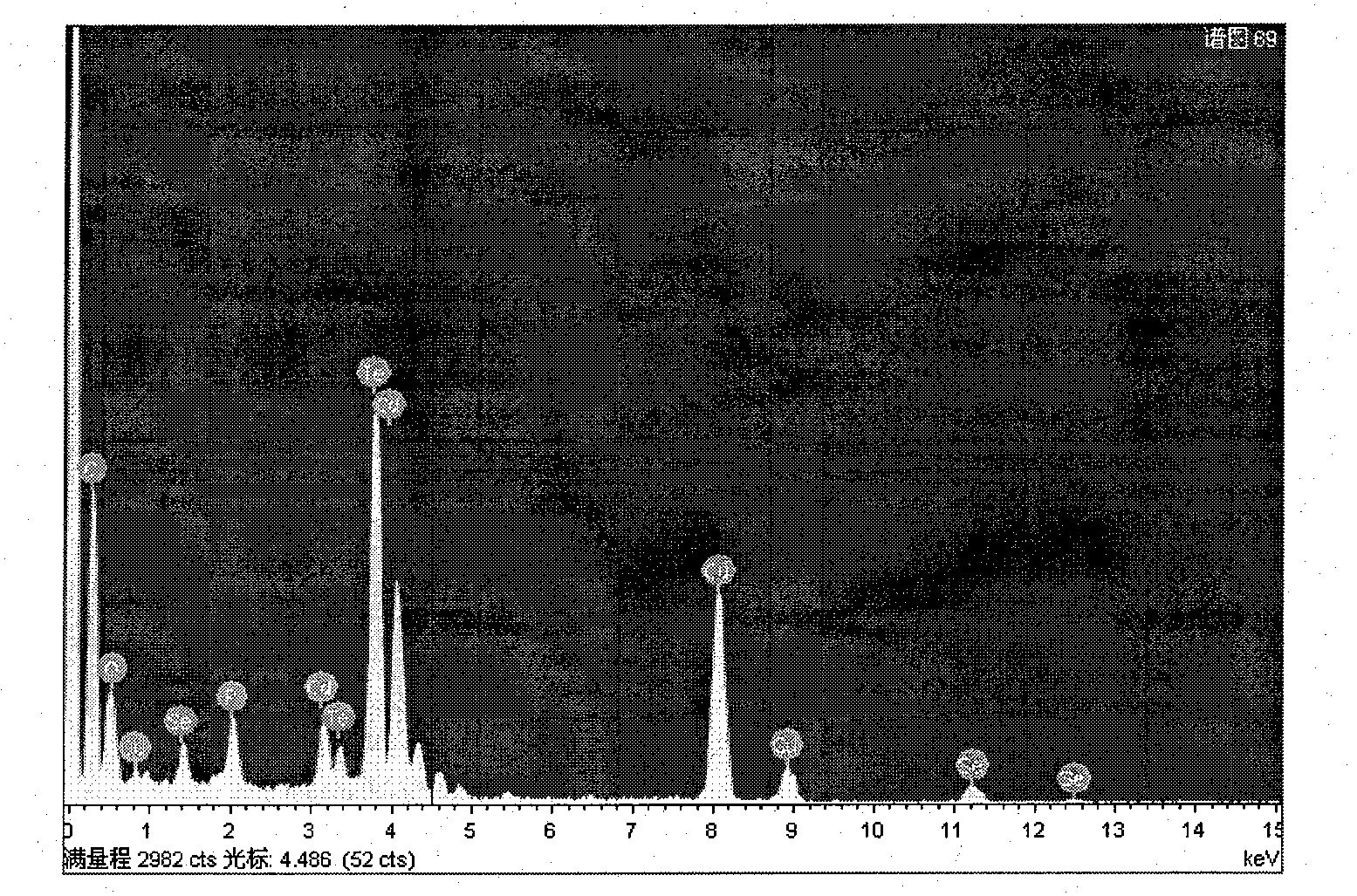

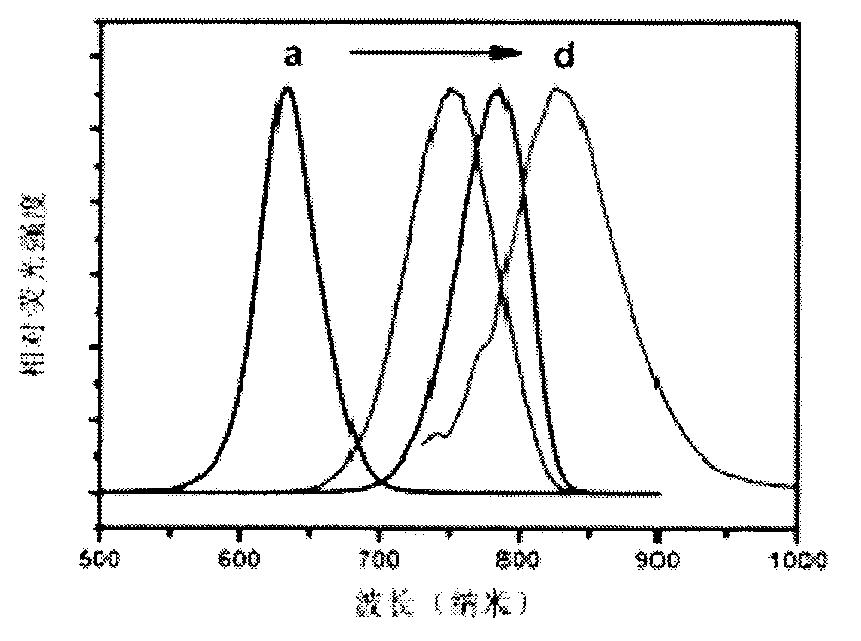

[0041] The invention provides a method for preparing water-soluble near-infrared quantum dots, which uses CdTeSe as the core, and adjusts the fluorescence emission wavelength of quantum dots by adjusting the ratio of tellurium components. The obtained quantum dots have a fluorescence emission wavelength of 600nm to 850nm.

[0042] Furthermore, CdTeSe is coated with a single precursor, zinc diethylthiocarbamate, to obtain CdTeSe / ZnS quantum dots. ZnS coating can improve the quantum yield of the product and increase its stability; reduce the content of Cd on the surface of the product and reduce its toxicity.

[0043] Finally, the synthesized core-shell quantum dots were modified by hydration using imidazole polymers to obtain water-soluble near-infrared quantum dots. The water-soluble near-infrared quantum dots can be conveniently applied in bioluminescent labeling, fluorescent ion probes, semiconductor devices and other fields.

[0044] Specifically, the method for preparing ...

Embodiment 1

[0095] Growth of CdTeSe quantum dot core: 0.054g Cd(Ac) 2 , 1.2g trioctylphosphine oxide and 0.1g tetradecyl phosphoric acid were added to a 25mL three-neck round bottom flask, and N 2 and heated to 360°C. Te precursor solution (60 uL) and Se precursor solution (240 uL) precursor solutions were quickly injected into the reactor. The temperature was lowered to 320° C. to obtain a solution of CdTeSe quantum dot cores.

[0096] Encapsulation: Cool the solution of CdTeSe quantum dot core to 120°C, slowly add 0.5mL ZnS precursor solution dropwise to the reactor, react for 30 minutes and then rapidly raise the temperature to 180°C for 1h to obtain CdTeSe / ZnS quantum dot solution.

[0097] Separation: After cooling the CdTeSe / ZnS quantum dot solution to room temperature (25°C), add n-hexane and methanol solution with a volume ratio of 1:2, centrifuge to remove the precipitate, suck out the upper layer solution, add acetone, and use a separator at 4000 rpm centrifuge for 5 minutes,...

Embodiment 2

[0101] Growth of CdTeSe quantum dot core: 0.158g Cd(Ac) 2 , 1.2g trioctylphosphine oxide and 0.1g tetradecyl phosphoric acid were added to a 25mL three-neck round bottom flask, and N 2 and heated to 360°C. Te precursor solution (15uL) and Se precursor solution (285uL) precursor solutions were injected rapidly into the reactor. The temperature was lowered to 320° C. to obtain a solution of CdTeSe quantum dot cores.

[0102] Encapsulation: Cool the solution of CdTeSe quantum dot core to 120°C, slowly add 0.5mL ZnS precursor solution dropwise to the reactor, react for 30 minutes and then rapidly raise the temperature to 180°C for 1h to obtain CdTeSe / ZnS quantum dot solution.

[0103] Separation: same as Example 1

[0104] Hydration modification: Take 15mg of CdTeSe / ZnS quantum dot powder and add it to 1mL chloroform to dissolve, weigh 30mg polymer modifier and add it to 1mL dimethyl sulfoxide solution, add the polymer modifier solution to the quantum dot solution and mix well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com