Polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable, high-density polyethylene technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of loss of life and property, obstruction of safe evacuation and fire extinguishing work, etc., to achieve reasonable formula and high mechanical performance , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

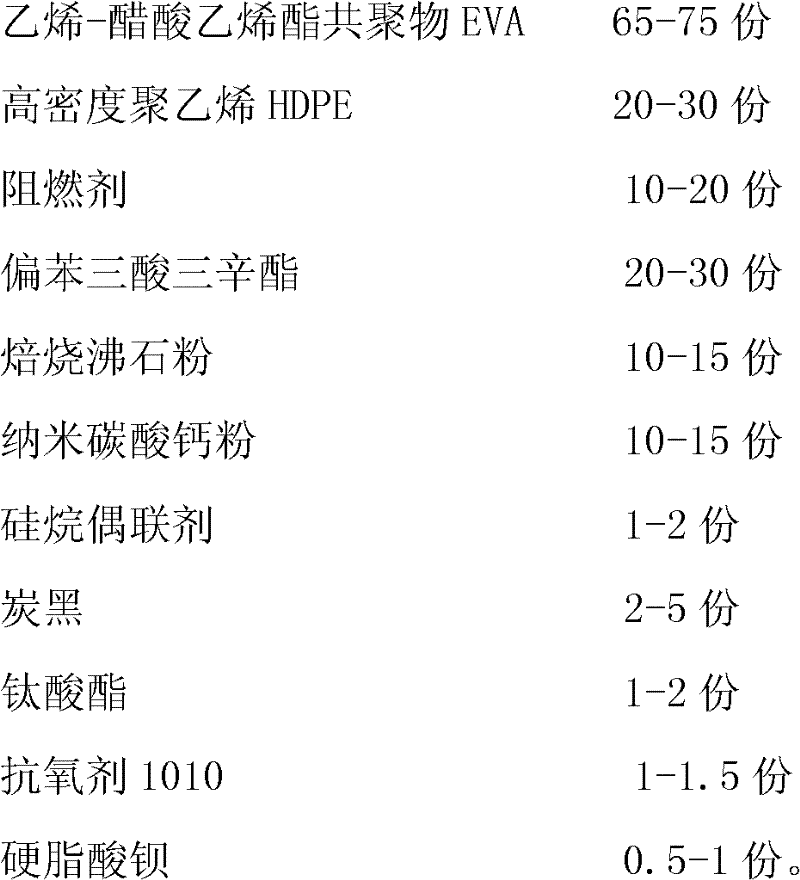

[0014] Embodiment 1: polyvinyl chloride cable material, the parts by weight of its constituent raw materials are:

[0015]

[0016] The preparation method of polyvinyl chloride cable material comprises the following steps:

[0017] (1) Take each raw material by the weight part that forms raw material, ethylene-vinyl acetate copolymer EVA, high-density polyethylene HDPE, trioctyl trimellitate, part roasted zeolite powder and nano calcium carbonate powder are mixed uniformly, Obtain mixture A;

[0018] (2) Add aluminum hydroxide, carbon black, silane coupling agent, titanate, antioxidant 1010 and barium stearate by weight in the mixture A in the above-mentioned steps (1), and stir at a low speed for 1 -2 minutes, make the mixing evenly, obtain the mixture B;

[0019] (3) Add the mixture B obtained in the above step (2) into an open mill, an internal mixer or a twin-screw extruder for mixing and granulation, and control the temperature at 140-170° C. to obtain a finished pro...

Embodiment 2

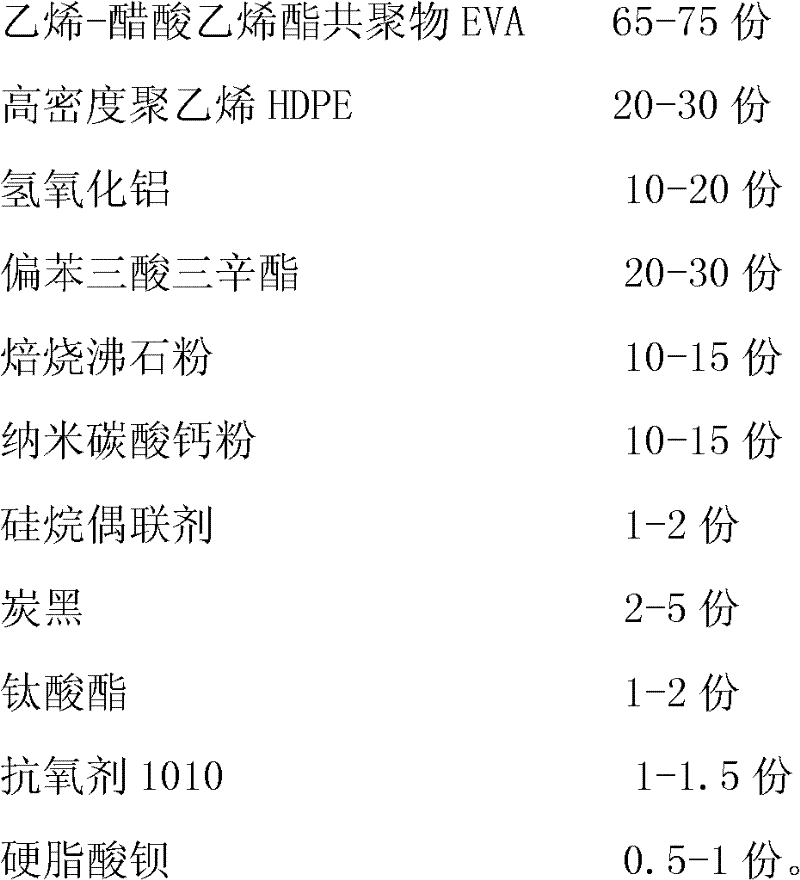

[0020] Embodiment 2: polyvinyl chloride cable material, the weight portion of its composition raw material is:

[0021]

[0022] The preparation method of polyvinyl chloride cable material comprises the following steps:

[0023] (1) Take each raw material by the weight part that forms raw material, ethylene-vinyl acetate copolymer EVA, high-density polyethylene HDPE, trioctyl trimellitate, part roasted zeolite powder and nano calcium carbonate powder are mixed uniformly, Obtain mixture A;

[0024] (2) Add aluminum hydroxide and magnesium hydroxide mixture, carbon black, silane coupling agent, titanate, antioxidant 1010 and barium stearate by weight in the compound A in above-mentioned step (1), Stir at low speed at room temperature for 1-2 minutes to make the mixture uniform and obtain mixture B;

[0025] (3) Add the mixture B obtained in the above step (2) into an open mill, an internal mixer or a twin-screw extruder for mixing and granulation, and control the temperatur...

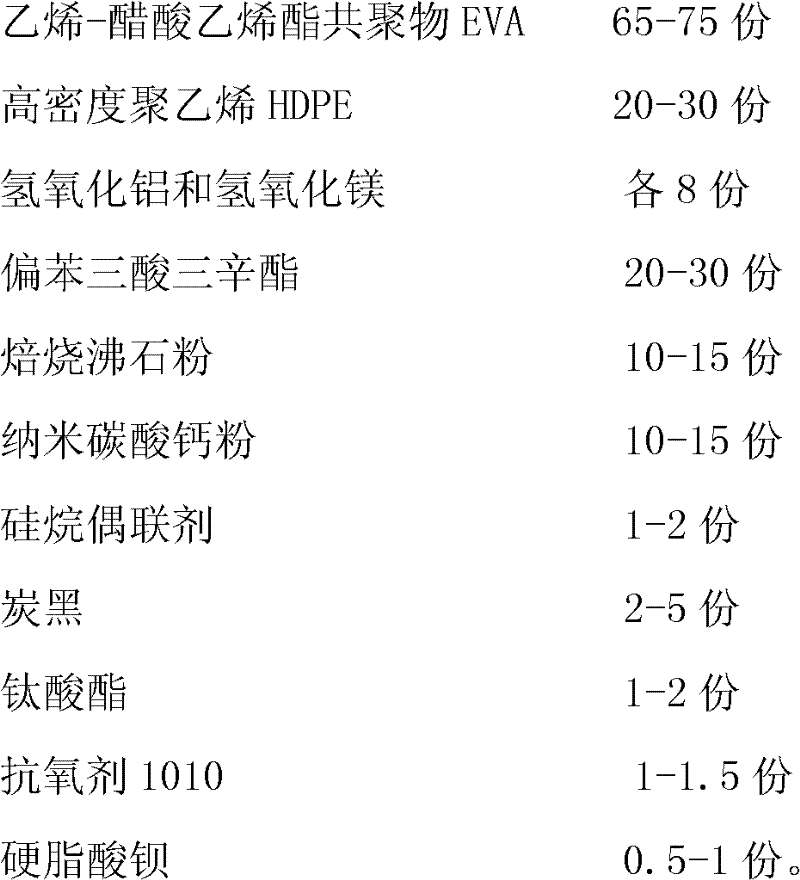

Embodiment 3

[0026] Embodiment 3: cable material of the present invention compares with existing cable material general performance:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com