High-weatherability chlorinated polyethylene power cord sheath material and preparation method thereof

A technology of chlorinated polyethylene and chlorosulfonated polyethylene, applied in circuits, electrical components, insulating cables, etc., can solve the problems of easy deformation, poor weather aging resistance, and affecting the safe operation of power lines, and achieve excellent electrical The effect of excellent insulation, weathering resistance and good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

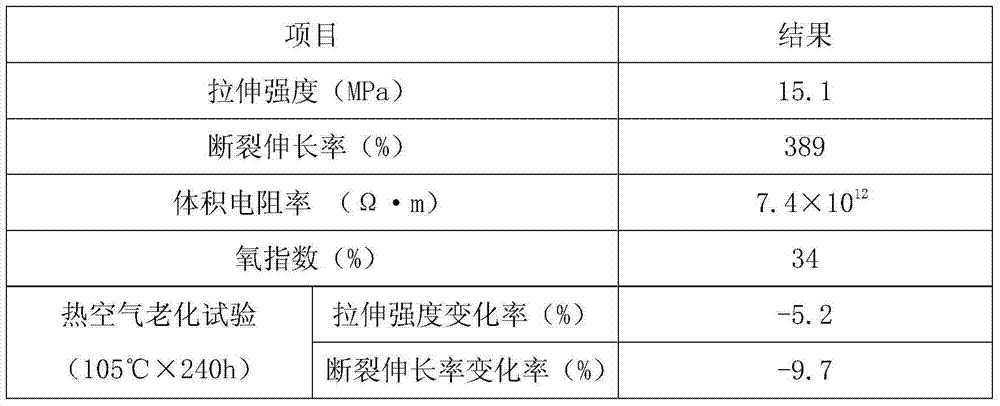

Examples

Embodiment Construction

[0012] A high weather resistance chlorinated polyethylene power cord sheath material, made of the following raw materials in weight (kg): chlorosulfonated polyethylene rubber (CSM2305) 80, EPDM rubber (4770R) 20, SEBS12, high activity Magnesium oxide 4, microcrystalline paraffin wax 3, talc powder 18, carbon black N550 25, black smoke gum 8, triallyl isocyanurate 2, 1,3-bis(tert-butylperoxyisopropyl)benzene 0.6 , trioctyl trimellitate 12, dioctyl phthalate 10, antioxidant 168 1.5, antimony trioxide 8, environmental protection flame retardant FR-T801 10, dibenzothiazole disulfide 2, hexasulfide Dipentamethylenethiuram 1.5, dibenzothiazole disulfide 1, nickel dibutyldithiocarbamate 2, composite filler 5;

[0013] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): pyrophyllite 10, diopside 8, opalite 6, N-2-(aminoethyl)-3-aminopropyltrimethoxy Silane 1.5, calcium lignosulfonate 2, sodium silicate 4, tourmaline slag 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com