Transparent polyvinyl chloride profile formula applied to led rainbow light strip

A technology of polyvinyl chloride and rainbow lights, which is applied in the field of transparent polyvinyl chloride profile formulations, can solve the problems of easy aging and damage, lack of plastic materials, and easy precipitation, etc., and achieve the effect of excellent weather aging resistance and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following parts by weight of the core wire material and the outer coating material are weighed, kneaded and blended respectively by a high-speed mixer, and then extruded by a parallel twin-screw extruder to be hot-cut and granulated for later use.

[0046] Core material: 100 parts of PVC resin powder, 60 parts of plasticizer, 1.5 parts of heat stabilizer, 0.4 parts of external lubricant, and 0.2 parts of internal lubricant;

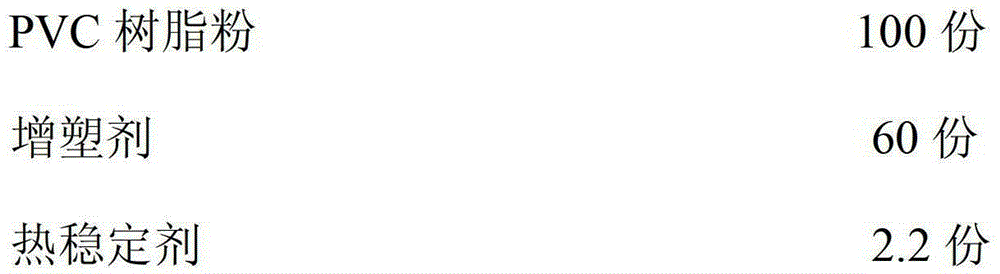

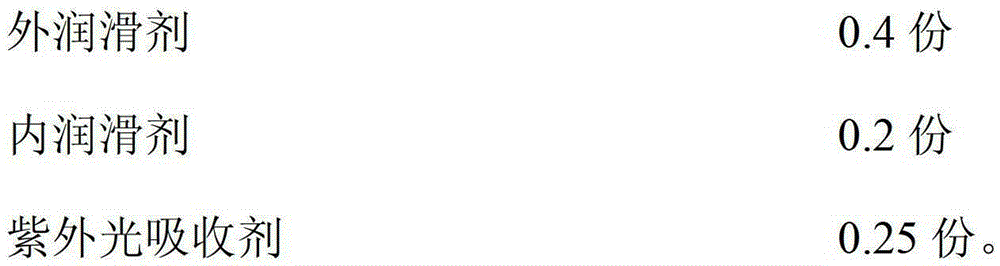

[0047] Cover material: 100 parts of PVC resin powder, 60 parts of plasticizer, 2.2 parts of heat stabilizer, 0.4 part of external lubricant, 0.2 part of internal lubricant, 0.25 part of ultraviolet light absorber;

[0048] According to the secondary molding process of PVC LED light strips, the core wire of the light strip is first formed with core wire material and tinned copper wire at one time, and then the core wire is covered with outer coating material to form a pipeline.

Embodiment 2

[0050] The following parts by weight of the core wire material and the outer coating material are weighed, kneaded and blended by a high-speed mixer, and then extruded and granulated by a parallel twin-screw extruder for subsequent use.

[0051] Core material: 100 parts of PVC resin powder, 60 parts of plasticizer, 1.5 parts of heat stabilizer, 0.4 part of external lubricant, 0.2 part of internal lubricant, 0.004 part of whitening agent, 0.002 part of ultramarine pigment;

[0052] Outer coating: 100 parts of PVC resin powder, 60 parts of plasticizer, 2.2 parts of heat stabilizer, 0.4 part of external lubricant, 0.2 part of internal lubricant, 0.25 part of ultraviolet light absorber, 0.004 part of whitening agent, 0.002 part of ultramarine blue pigment share;

[0053] According to the secondary molding process of PVC LED light strips, the core wire of the light strip is first formed with core wire material and tinned copper wire at one time, and then the core wire is covered wi...

Embodiment 3

[0055] The following parts by weight of the core wire material and the outer coating material are weighed, kneaded and blended by a high-speed mixer, and then extruded and granulated by a parallel twin-screw extruder for subsequent use.

[0056] Core material: 100 parts of PVC resin powder, 60 parts of plasticizer, 1.5 parts of heat stabilizer, 0.4 parts of external lubricant, 0.2 part of internal lubricant, and 0.002 parts of other pigments;

[0057] Cover material: 100 parts of PVC resin powder, 60 parts of plasticizer, 2.2 parts of heat stabilizer, 0.4 part of external lubricant, 0.2 part of internal lubricant, 0.25 part of ultraviolet light absorber, 0.004 part of whitening agent, 0.002 part of other pigments share;

[0058] According to the secondary molding process of PVC LED light strips, the core wire of the light strip is first formed with core wire material and tinned copper wire at one time, and then the core wire is covered with outer coating material to form a pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com