PVC (Polyvinyl Chloride) sealing strip and application thereof

A sealing strip and PVC resin technology, applied in the field of materials, can solve problems such as non-compliance, poor resilience, and migration resistance, and achieve the effects of improving resilience performance, improving migration resistance, and high migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

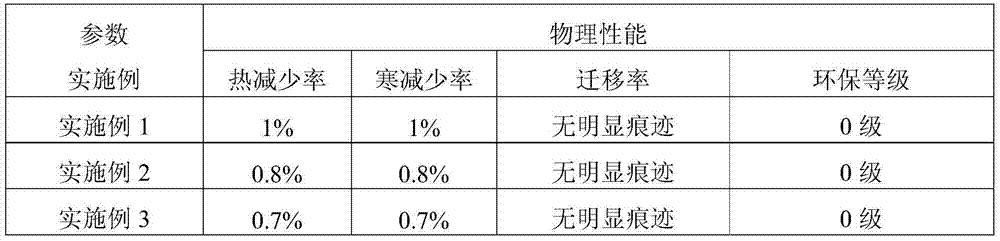

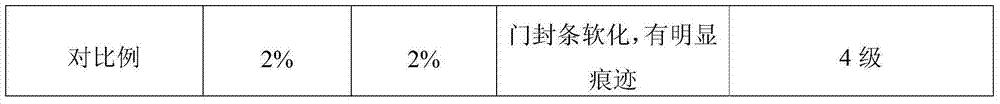

Examples

Embodiment 1

[0044] Raw material formula:

[0045] 100g of PVC resin (Formosa Plastics S-70), 40g of combined plasticizer containing diisononyl adipate plasticizer and trioctyl trimellitate plasticizer, 5g of epoxy soybean oil plasticizer agent, 10g of polyester plasticizer (PN7030), 5g of elastomer (P83), 5g of Ca-Zn stabilizer, 30g of calcium carbonate (LD-800), 5g of lubricant (stearic acid), 1g Titanium dioxide pigment, 1-3g antioxidant and thermal aging agent and 0.5-2g antibacterial and antifungal agent.

[0046] Preparation:

[0047] First mix and stir the pigment, additives, antibacterial and antifungal agent and Ca-Zn stabilizer to obtain a stabilizer mixture, then put the PVC resin into a high-speed mixer, stir at a low speed first, and then mix the obtained stabilizer mixture Stir for 5 minutes after adding, then slowly add the plasticizer one by one with stirring, turn to high speed after spraying the plasticizer, adjust the high and low speed to control the temperature of the ...

Embodiment 2

[0049] Raw material formula:

[0050] 100g of PVC resin (Formosa Plastics S-70), 40g of trioctyl trimellitate plasticizer, 5g of epoxy soybean oil plasticizer, 10g of polyester plasticizer (PN7030), 10g of powder Nitrile (P83), 5g of Ca-Zn stabilizer, 30g of calcium carbonate (LD-800), 5g of lubricant (stearic acid), 0.2-1g of titanium dioxide pigment, 1-3g of antioxidant and heat aging agent and 0.5-2g antibacterial and antifungal agent.

[0051] Preparation method: with embodiment 1.

Embodiment 3

[0053] Raw material formula:

[0054] 100g of PVC resin (Formosa Plastics S-70), 30g of diisononyl adipate plasticizer, 10g of trioctyl trimellitate plasticizer, 5g of epoxy soybean oil plasticizer, 15g of Polyester plasticizer (PN7030), 5g of powdered nitrile (P83), 5g of Ca-Zn stabilizer, 30g of calcium carbonate (LD-800), 5g of lubricant (paraffin wax and stearic acid combination), 0.2- 1g of titanium dioxide pigment, 1-3g of antioxidant and thermal aging agent and 0.5-2g of antibacterial and antifungal agent.

[0055] Preparation method: with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com