Hot-melt pressure sensitive adhesive for automobile interior part

A technology for hot-melt pressure-sensitive adhesives and automotive interior parts, which is applied in the directions of adhesives, adhesive types, mineral oil-hydrocarbon copolymer adhesives, etc. High problems, to achieve the effect of excellent bonding and sealing performance, high production efficiency, good softness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

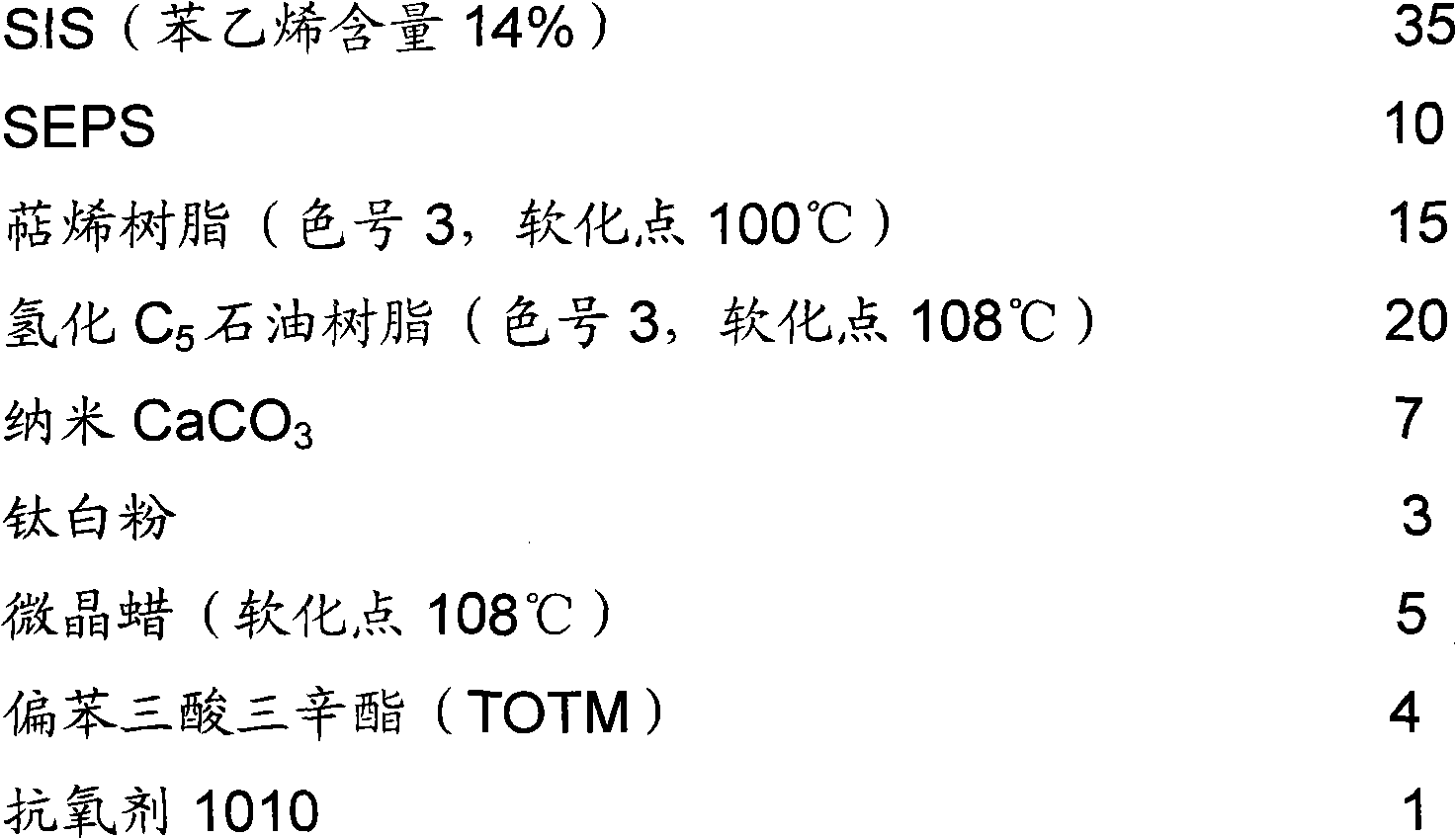

[0020] Embodiment 1: Automobile hot-melt pressure-sensitive adhesive component ratio (mass %)

[0021]

[0022] SIS, SEPS, TOTM and antioxidants were weighed in proportion and added to a horizontal kneader that had been preheated for 60 minutes (wall temperature 180°C), kneaded for 40 minutes, and then added proportionally weighed terpene resin, hydrogenated C 5 Petroleum resin, microcrystalline wax, titanium dioxide, and nano fillers were kneaded at high temperature (175°C) for 40 minutes. Pour into a 25cm×15cm×7cm cube box (lined with high-temperature release paper) in a molten state, and wrap it with release paper after cooling.

Embodiment 2

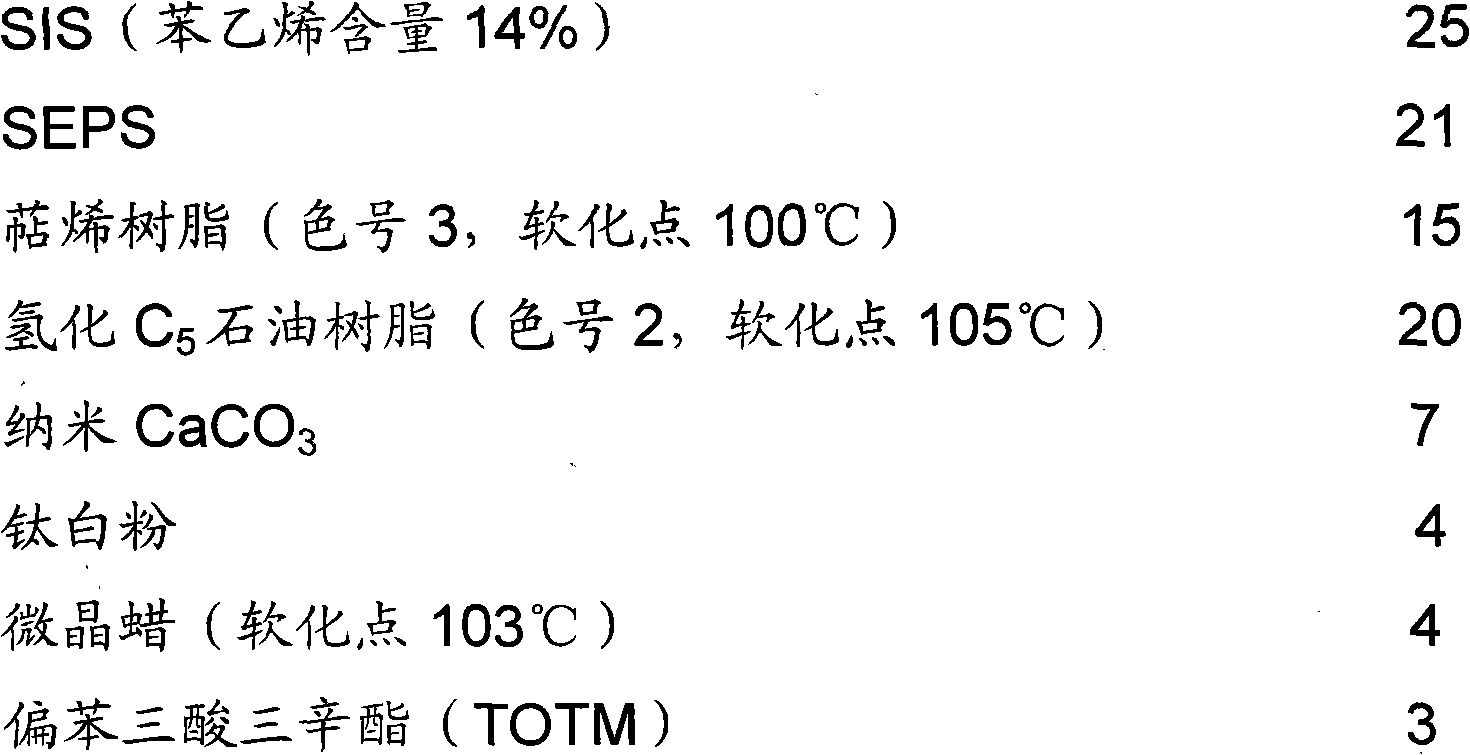

[0023] Embodiment 2: automobile hot-melt pressure-sensitive adhesive component ratio (mass %)

[0024]

[0025]

[0026] SIS, SEPS, TOTM and antioxidants were weighed in proportion and added to a horizontal kneader that had been preheated for 70 minutes (wall temperature 190°C). After kneading for 40 minutes, terpene resin, hydrogenated C 5 Petroleum resin, microcrystalline wax, titanium dioxide, and nano fillers were kneaded at high temperature (170°C) for 50 minutes. Pour into a 25cm×15cm×7cm cube box (lined with high-temperature release paper) in a molten state, and wrap it with release paper after cooling.

Embodiment 3

[0027] Embodiment 3: automobile hot-melt pressure-sensitive adhesive component ratio (mass %)

[0028]

[0029] SIS, SEPS, TOTM and antioxidants were weighed in proportion and added to a horizontal kneader that had been preheated for 60 minutes (wall temperature 180°C), kneaded for 40 minutes and then added proportionally weighed terpene resin, hydrogenated C 5 Petroleum resin, microcrystalline wax, titanium dioxide, and nano fillers were kneaded at high temperature (185°C) for 60 minutes. Pour into a 25cm×15cm×7cm cube box (lined with high-temperature release paper) in a molten state, and wrap it with release paper after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com