Low-odor flame retardant styrene-based resin composition and preparation method thereof

A styrene-based resin and composition technology, applied in the field of resin composition and its preparation, can solve the problems of material pollution to the working environment, human injury, etc., and achieve the effects of reducing the risk of discoloration, reducing odor, and reducing the plasticizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

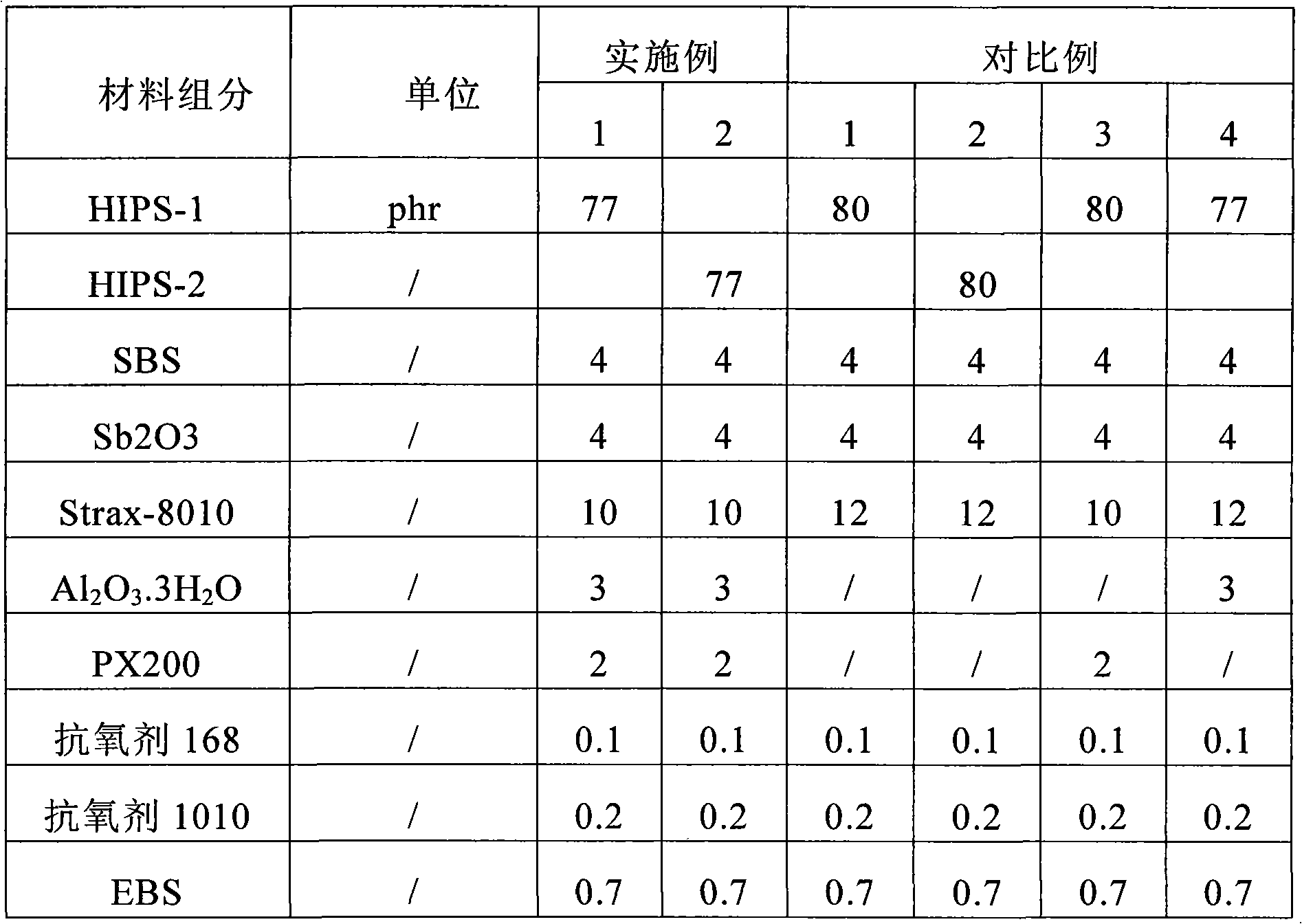

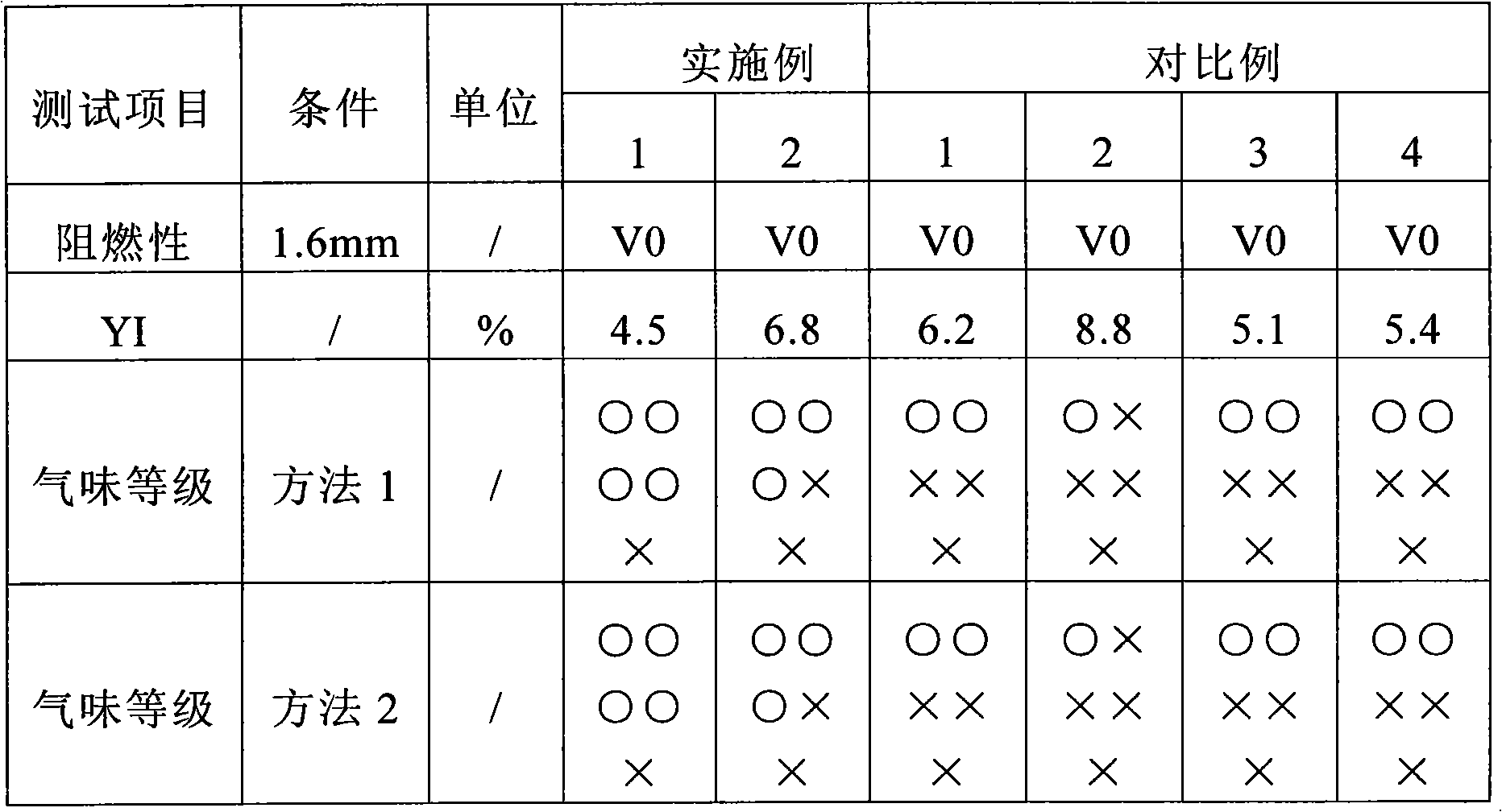

Embodiment 1~2

[0040] In order to realize the present invention, the inventors innovatively obtained a low-odor resin composition by adding phosphorus-containing compounds and hydrated metal oxides. The principle is as follows: 1) The plasticizing effect of phosphorus-containing compounds such as aromatic phosphate itself reduces the plasticizing temperature of the material and reduces the production of secondary oligomers in styrene resin; 2) P-Br synergistically stabilizes the heat The amount of bromine flame retardants with poor properties is reduced, which improves the thermal stability of the material and reduces the content of free bromine; 3) The endothermic effect during the dehydration process of hydrated metal oxides can reduce the heat loss caused by the overheating of the melt. The risk of flame retardant degradation and the generation of secondary oligomers; 4) the dehydration temperature of the hydrated metal oxide used in the present invention is close to the blending temperatu...

Embodiment 3

[0059] A preparation method of a low-odor flame-retardant styrene-based resin composition, the method comprising the following steps:

[0060] (1) Prepare materials according to the following components and parts by weight: 60kg of styrene-based resin, 10kg of impact modifier, 8kg of brominated flame retardant, 1kg of flame-retardant synergist, 0.5kg of phosphorus-containing compound, and 1kg of hydrated metal oxide , wherein the styrene-based resin is a styrene-butadiene-acrylonitrile terpolymer, the content of styrene residues is less than 200ppm, and the melt flow rate of the resin is 3g / 10min (ASTM D1238, test conditions: 200°C×5kg ), there is no irritating smell after baking at 80°C for 30 minutes, the impact modifier is styrene-butadiene block copolymer, the rubber content is 50wt%, and the brominated flame retardant is tetrabromobisphenol A, which is flame retardant The synergist is antimony trioxide with a particle size of less than 2000 meshes, the phosphorus compound...

Embodiment 4

[0064] A preparation method of a low-odor flame-retardant styrene-based resin composition, the method comprising the following steps:

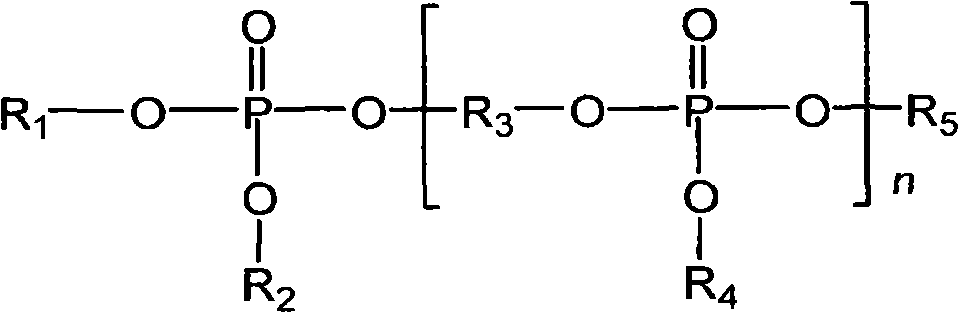

[0065] (1) Prepare materials according to the following components and parts by weight: styrene-based resin 80kg, brominated flame retardant 20kg, flame-retardant synergist 5kg, phosphorus-containing compound 5kg, hydrated metal oxide 3kg, wherein styrene-based resin is Styrene-acrylate-acrylonitrile terpolymer, styrene residue content <100ppm, melt flow rate of the resin is 18g / 10min (ASTM D1238, test condition: 200℃×5kg), after baking at 80℃ for 30min There is no irritating odor, the brominated flame retardant is a mixture of decabromodiphenylethane and 2,4,6-tribromotriphenoxy-1,3,5-triazine, and the flame retardant synergist is colloid Antimony pentoxide, the molecular formula of phosphorus-containing compounds is as follows:

[0066]

[0067] R1, R2, R4, and R5 are respectively selected from C6, C10, and C12C20 aromatic groups substit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com