High temperature resistant PVC reinforced hose and preparation method thereof

A high-temperature-resistant hose technology, applied in the field of high-temperature-resistant PVC reinforced hose and its preparation, can solve the problems of unusable children's toys and high prices, and achieve improved thermal stability, increased strength and toughness, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

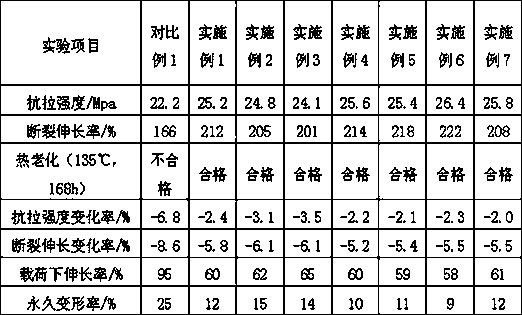

Examples

Embodiment 1

[0029] High temperature resistant PVC reinforced hose, including inner tube and outer tube, said inner tube or outer tube, in parts by mass, includes the following components: 50 parts of SG-3 type PVC and 50 parts of high polymerization degree of 2500 PVC, 1.5 parts of composite calcium zinc heat stabilizer, 35 parts of TOTM, 10 parts of PPA-2000 polyester plasticizer, 2 parts of ACR toughening modifier, 10 parts of calcium carbonate filler with an average particle size of 1 μm, 1 part Antioxidant 1010 and 0.2 parts of toner.

Embodiment 2

[0031] High temperature resistant PVC reinforced hose, including inner tube and outer tube, said inner tube or outer tube, in parts by mass, includes the following components: 50 parts of SG-3 type PVC and 50 parts of high polymerization degree of 2300 PVC, 3 parts of organotin heat stabilizer, 30 parts of TOTM, 12 parts of PPA-2500 polyester plasticizer, 2 parts of MBS toughening modifier, 15 parts of calcium carbonate filler with an average particle size of 0.1 μm, 2 parts Antioxidant 1010 and 0.5 parts of toner.

Embodiment 3

[0033] High temperature resistant PVC reinforced hose, including inner tube and outer tube, said inner tube or outer tube, in parts by mass, includes the following components: 50 parts of SG-3 type PVC and 50 parts of high polymerization degree of 2800 PVC, 2 parts of rare earth heat stabilizer, 25 parts of TOTM, 15 parts of PPA-1500 polyester plasticizer, 3 parts of EVA toughening modifier, 15 parts of calcium carbonate filler with an average particle size of 0.5 μm, 1 part of anti- Oxygen 1076 and 0.1 parts of toner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com