Environment-friendly low-temperature curing PVC plastisol and preparation method thereof

An environment-friendly, plastisol technology, applied in the field of environment-friendly low-temperature curing PVC plastisol and its preparation, can solve the problems of low mechanical properties, high curing temperature, unenvironmental PVC plastisol, etc. The effect of plasticizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

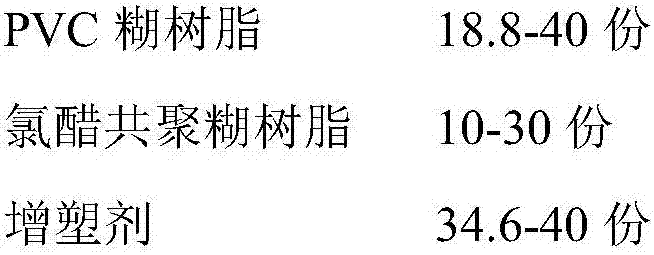

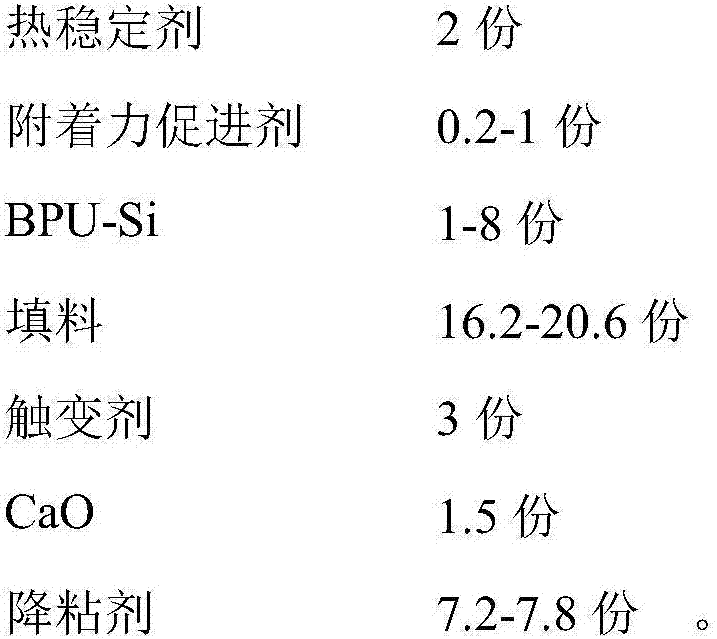

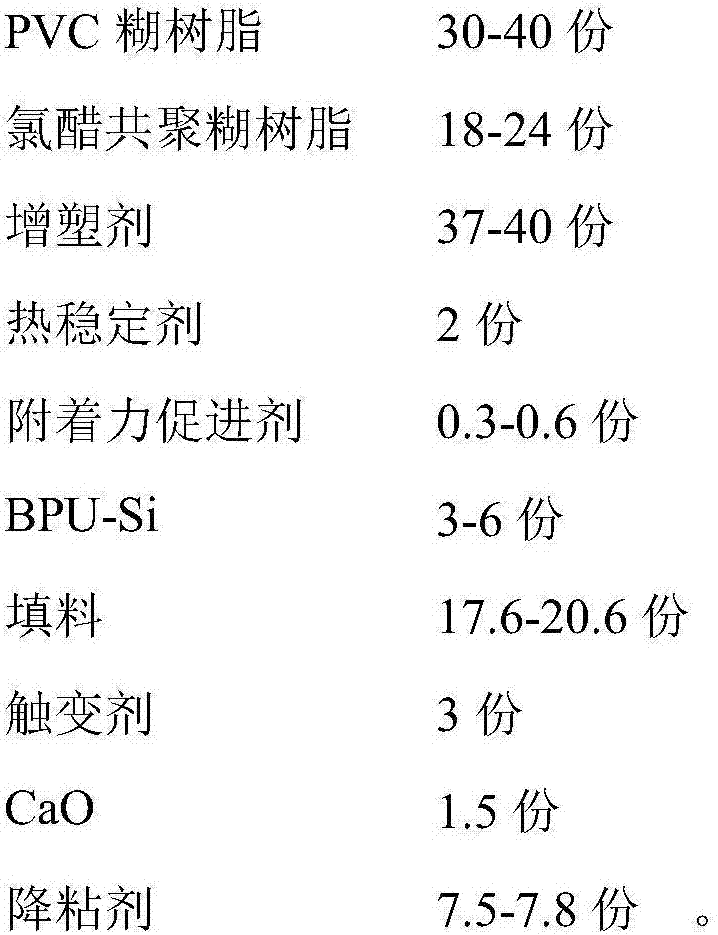

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, add the adhesion promoter to the plasticizer and disperse evenly, then add PVC paste resin and vinyl chloride copolymer paste resin in turn, stir at 1000rpm for 5min, then add filler, stir at 2200rpm for 5min, then add heat stabilizer agent, thixotropic agent and CaO, stirred at 2800rpm for 8min, and the obtained mixture was ground by a three-roller mill to a fineness≤120μm (determined fineness with a scraper fineness meter), and then added viscosity reducer, at 3000rpm Stir at low temperature for 10 minutes, finally add BPU-Si, defoam at a vacuum of 0.095MPa for 15 minutes, then mature at room temperature for 24 hours, bake at 120-130°C for 25 minutes, and cool at room temperature for 12 hours to obtain PVC plastisol .

[0032] Wherein the PVC paste resin is a microsuspension polymer resin (PVC paste resin (TPM-31), industrial grade, Xinjiang Tianye) of a degree of polymerization of 1100, and the vinyl chloride-vinyl copolymer paste resin is a micr...

Embodiment 2

[0034] At room temperature, add the adhesion promoter to the plasticizer and disperse evenly, then add PVC paste resin and vinyl chloride copolymer paste resin in turn, stir at 1000rpm for 5min, then add filler, stir at 2200rpm for 5min, then add heat stabilizer agent, thixotropic agent and CaO, stirred at 2800rpm for 8min, and the obtained mixture was ground by a three-roller mill to a fineness≤120μm (determined fineness with a scraper fineness meter), and then added viscosity reducer, at 3000rpm Stir at low temperature for 10 minutes, finally add BPU-Si, defoam at a vacuum of 0.095MPa for 15 minutes, then mature at room temperature for 24 hours, bake at 120-130°C for 25 minutes, and cool at room temperature for 12 hours to obtain PVC plastisol .

[0035] Wherein the PVC paste resin is a microsuspension polymer resin (PVC paste resin (TPM-31), industrial grade, Xinjiang Tianye) of a degree of polymerization of 1200, and the vinyl chloride-vinyl chloride paste resin is a micro...

Embodiment 3

[0037]At room temperature, add the adhesion promoter to the plasticizer and disperse evenly, then add PVC paste resin and vinyl chloride copolymer paste resin in turn, stir at 1000rpm for 5min, then add filler, stir at 2200rpm for 5min, then add heat stabilizer agent, thixotropic agent and CaO, stirred at 2800rpm for 8min, and the obtained mixture was ground by a three-roller mill to a fineness≤120μm (determined fineness with a scraper fineness meter), and then added viscosity reducer, at 3000rpm Stir at low temperature for 10 minutes, finally add BPU-Si, defoam at a vacuum of 0.095MPa for 15 minutes, then mature at room temperature for 24 hours, bake at 120-130°C for 25 minutes, and cool at room temperature for 12 hours to obtain PVC plastisol .

[0038] Wherein the PVC paste resin is a microsuspension polymeric resin (PVC paste resin (TPM-31), industrial grade, Xinjiang Tianye) of a degree of polymerization of 1300, and the vinyl chloride-vinegar copolymer paste resin is a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com