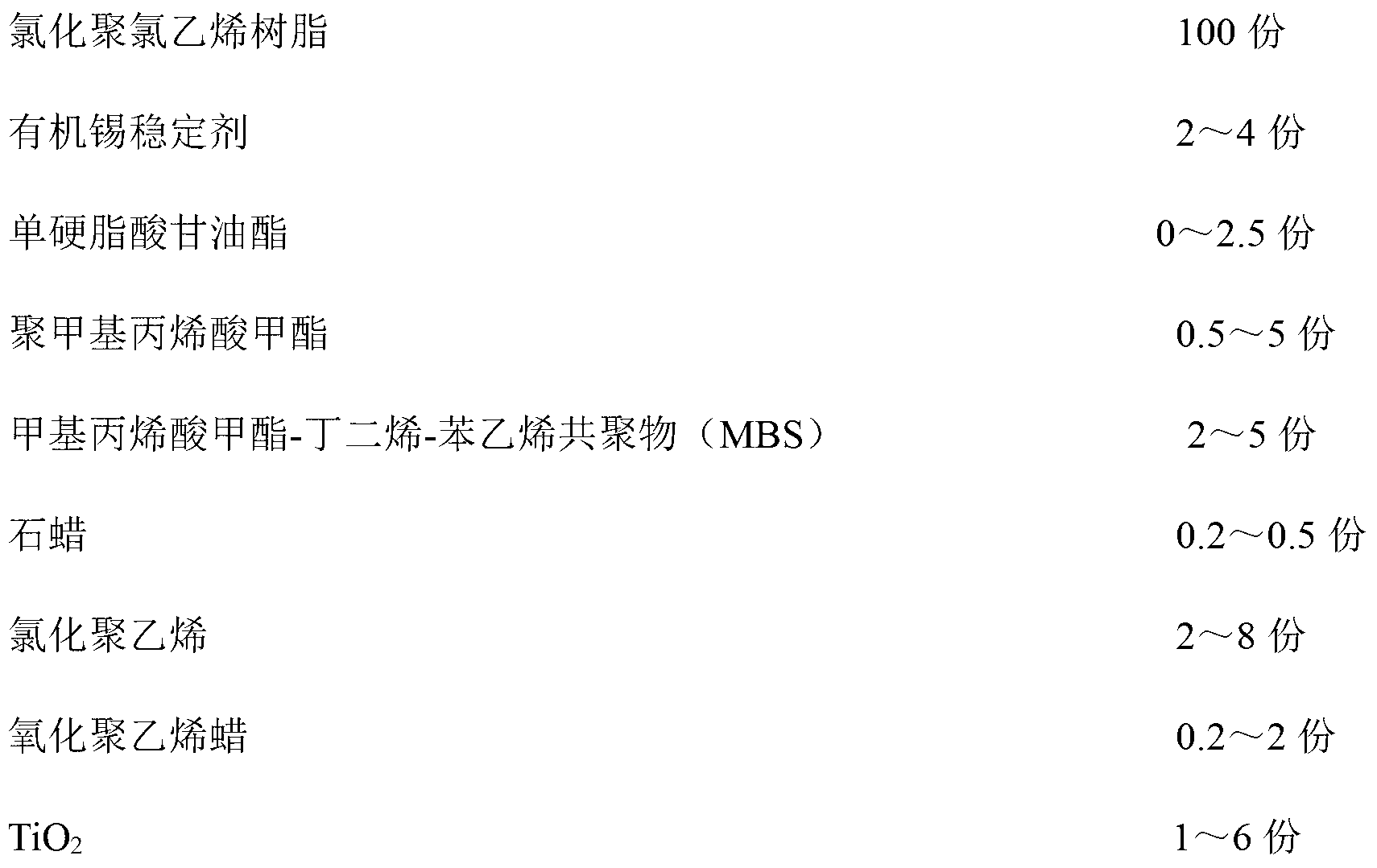

Chlorinated polyvinylchloride mixing material

A chlorinated polyvinyl chloride and chlorinated polypropylene technology, applied in the field of chlorinated polyvinyl chloride mixture, can solve the problem that the CPVC mixture cannot obtain smooth surface and good processing performance, the high-dimensional card is not easy to meet the standard, and the CPVC product loses and other problems, to achieve good demolding performance, increase operating flexibility, and improve processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4, comparative comparative example 5

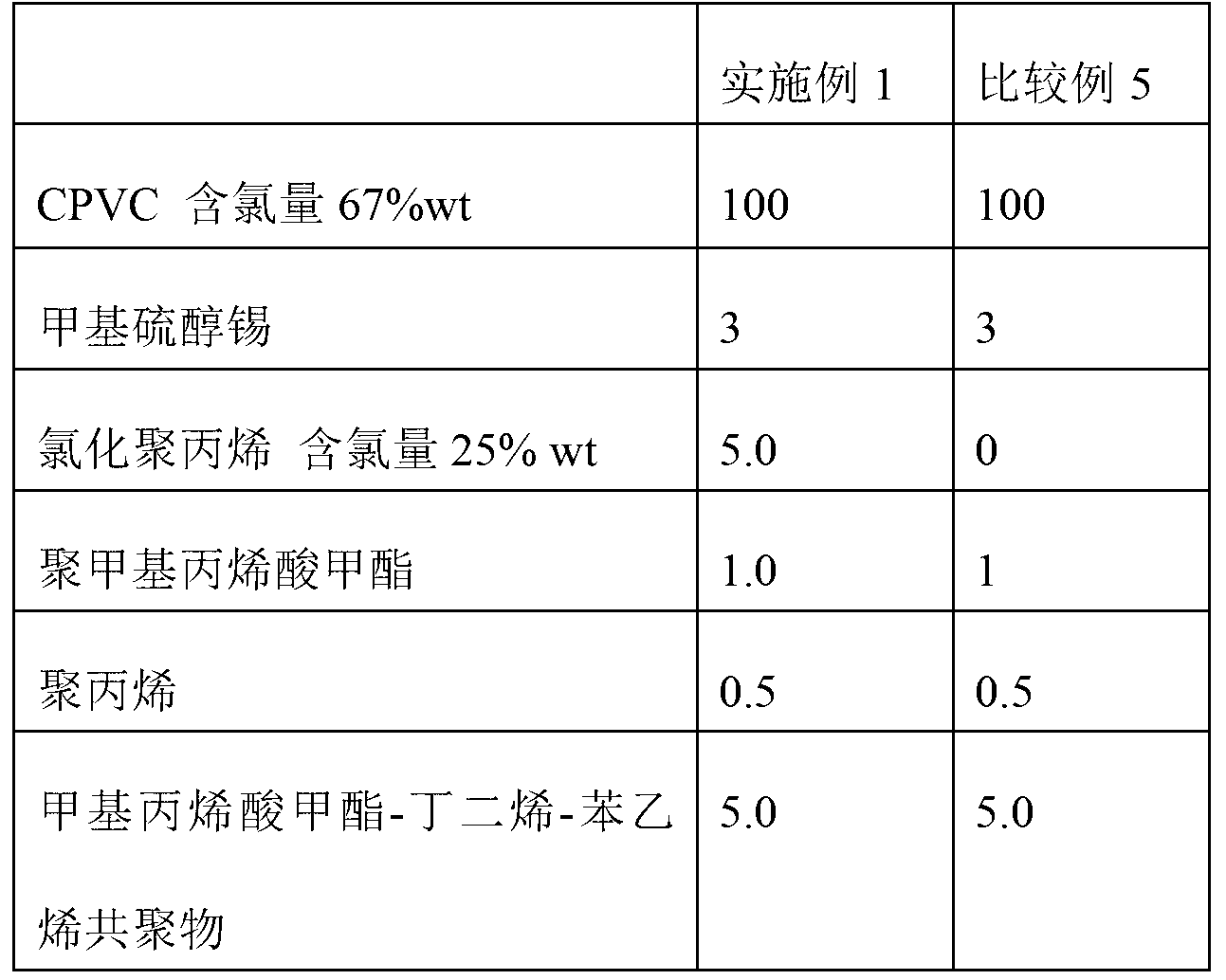

[0026] The formula is as in Table 1 and Table 2, all in parts by weight.

[0027] The preparation method is as follows: add organotin stabilizer, chlorinated polypropylene, and chlorinated polyethylene to chlorinated polyvinyl chloride resin and mix them in a mixer. The temperature rises to about 60-70 ° C, and other additives are added to mix to 100 After ~120°C, put it into a cooling mixer for cooling, cool down to below 45°C, and discharge, which is the product.

[0028] Table 1

[0029]

[0030]

[0031] As can be seen from Table 1, compared with Example 1 and Comparative Example 5, although the Vicat softening temperature of the compound added with chlorinated polypropylene is reduced, the processability and notched impact strength are greatly improved. And reduce the plasticizing temperature, improve the surface gloss, and broaden the processing width of CPVC.

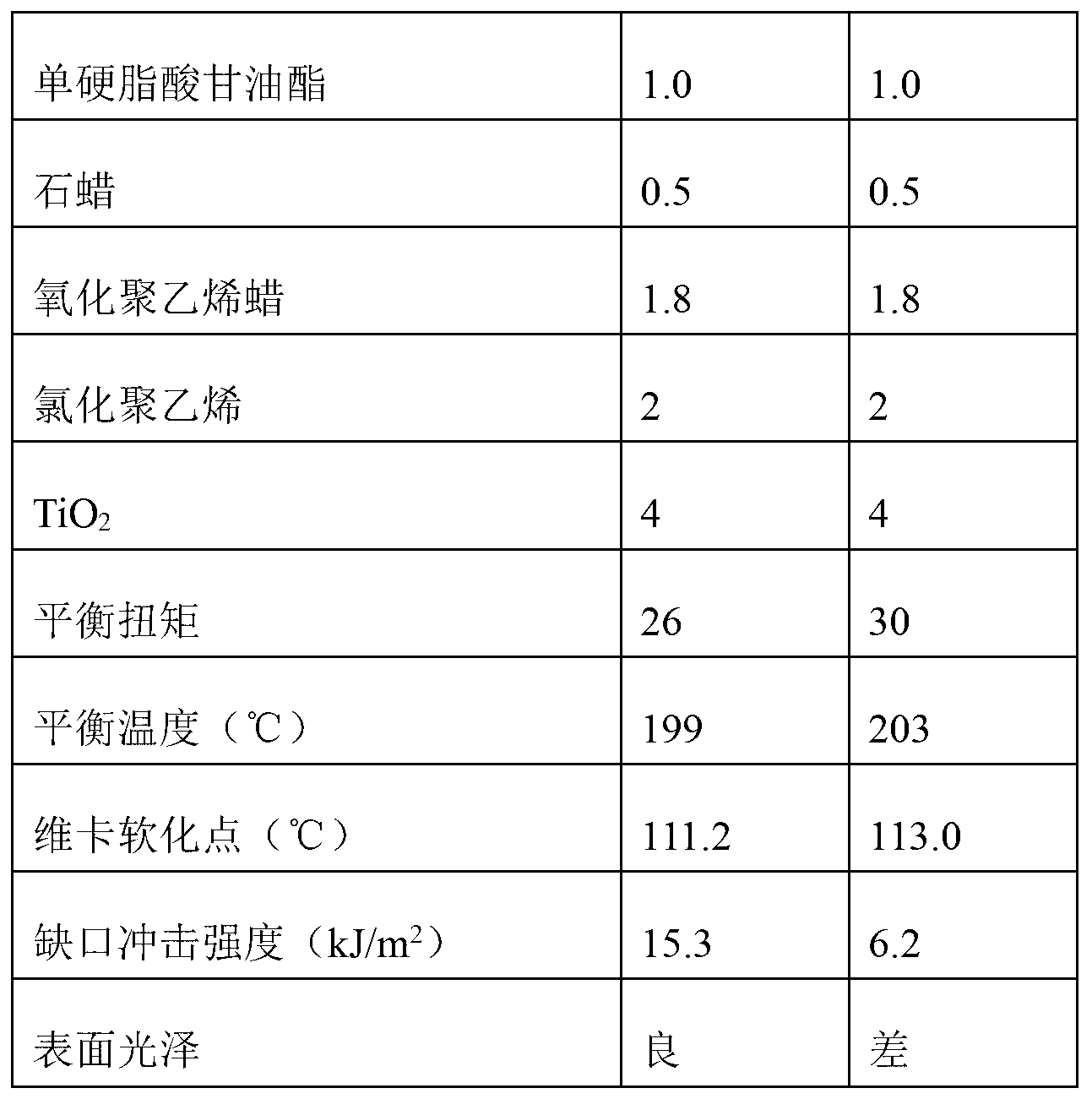

[0032] Table 2

[0033]

[0034]

[0035] It can be seen from Table 2 that with the addition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com