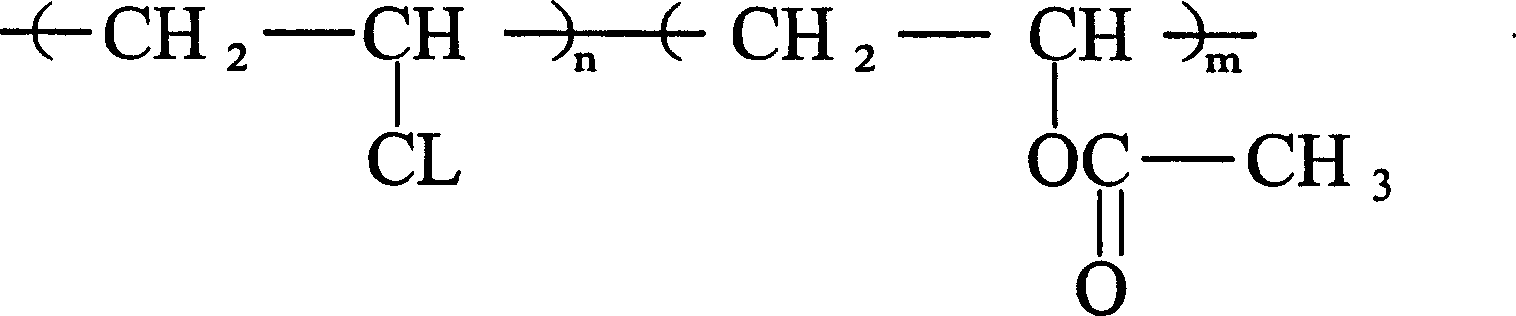

Prepn. of vinyl chloride-vinyl acetate copolymer resin

A technology for vinyl acetate copolymerization and resin blending, which is applied in the field of preparing vinyl chloride-vinyl acetate resin by a suspension method, can solve the problems of insufficiently compact structure, easy precipitation, poor viscosity reduction effect, etc., and achieves easy operation and improved flow and thixotropy. , the effect of low oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 14.25 kg of vinyl chloride, 0.75 kg of vinyl acetate, 0.014 kg of dimyristyl peroxide, 0.016 kg of trisodium citrate, 0.012 kg of sodium bicarbonate, 0.015 kg of hydroxypropyl methylcellulose and polypeptide polymer, 0.026 kg Put chlorinated paraffin and 27 kg of water in a polymerization kettle, react at a temperature of 58 ° C for 7 to 8 hours, add 0.003 kg of acetone thiosemicarbazone, and obtain an aqueous suspension of vinyl chloride-vinyl acetate copolymer blended resin , stripped with steam to remove unreacted vinyl chloride and vinyl acetate monomers, and centrifugally dried to obtain the finished product. The obtained finished product was tested according to the GB5761-93 standard, and the results are shown in Table 1.

Embodiment 2

[0033] 13.8 kg of vinyl chloride, 1.2 kg of vinyl acetate, 0.014 kg of dimyristyl peroxide, 0.018 kg of trisodium citrate, 0.012 kg of sodium bicarbonate, 0.015 kg of hydroxypropyl methylcellulose and polypeptide polymer, 0.026 kg 16, 18 mixed acid and 27 kg of water are placed in a polymerization kettle, reacted at a temperature of 58 ° C for 7 to 8 hours, and 0.003 kg of acetone thiosemicarbazide is added to obtain a vinyl chloride-vinyl acetate copolymer blended resin The aqueous suspension is stripped with steam to remove unreacted vinyl chloride and vinyl acetate monomers, and dried by centrifugation to obtain the finished product. The obtained finished product was tested according to the GB5761-93 standard, and the results are shown in Table 1.

Embodiment 3

[0035] 12.75 kg of vinyl chloride, 2.25 kg of vinyl acetate monomer, 0.015 kg of dimyristyl peroxide, 0.02 kg of trisodium citrate, 0.012 kg of sodium bicarbonate, 0.018 kg of hydroxypropyl methylcellulose and polypeptide polymer, Put 0.026 kg of octadecyl alcohol and 27 kg of water in a polymerization kettle, react at a temperature of 58 ° C for 7 to 8 hours, add 0.003 kg of bisphenol A, and obtain an aqueous suspension of vinyl chloride-vinyl acetate copolymer blended resin, water Steam stripping to remove unreacted vinyl chloride and vinyl acetate monomers, and centrifugal drying to obtain the finished product. The obtained finished product was tested using the GB576l-93 standard, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com